Chiyoda Seiki, Japan

Chiyoda Seiki Mid-sized Dual-use Device (For AC)

Made in Japan

Manufacturer: Chiyoda Seiki

Product name: Mid-sized Dual-use Device (For AC)

Specification

| Product Name | Specification | Crater No. | Crater Diameter (φ mm) | Processing Board Thickness (mm) | Gas Pressure (a) | Gas Consumption (L/h, Standard Condition) | Total Length (mm) | |||||

| Oxygen | Acetylene | Cutting Oxygen | Preheating Oxygen / Welding Oxygen |

Acetylene | Weight (g) | |||||||

| Medium Size | Glitter | New Glitter | ||||||||||

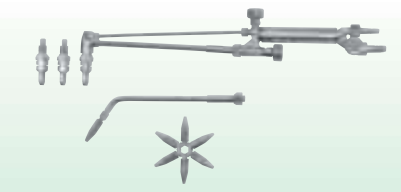

| NEO (NEO) Type features a medium construction glitter design with a medium construction device. It includes 3 cutting tips and 7 welding tips for versatile functionality. | 1 Type 1 (Cutter) |

0 | 0.6 | ~5 | 0.25 | 0.025 | 550 | 220 | 200 | 485(465) | 465 | 420 |

| 1 | 0.7 | 3 ~ 7 | 0.25 | 0.025 | 750 | 245 | 220 | Blowing Pipe 755 Welding Pipe 75 |

Blowing Pipe 670 Welding Pipe 75 |

Blowing Pipe 530 Welding Pipe 75 |

||

| 2 | 0.9 | 5 ~ 15 | 0.25 | 0.025 | 1250 | 275 | 20 | |||||

| 3 | 1.1 | 10 ~ 20 | 0.25 | 0.025 | 1850 | 315 | 280 | |||||

| Type 01 (Welder) |

200 | 1.2 | 1.5~2 | 0.3 | 0.03 | 220 | 20 | |||||

| 225 | 1.3 | 2~2.3 | 0.3 | 0.03 | 250 | 225 | ||||||

| 250 | 1.4 | 2.3 ~ 2.5 | 0.3 | 0.03 | 275 | 2500 | ||||||

| 315 | 1.5 | 2.5~3.2 | 0.3 | 0.03 | 350 | 315 | Cutting Tip 65 Welding Tip 25 |

|||||

| 400 | 1.6 | 3.2~4 | 0.3 | 0.03 | 440 | 400 | ||||||

| 450 | 1.7 | 4~4.5 | 0.3 | 0.03 | 495 | 450 | ||||||

| 500 | 1.8 | 4.5~5 | 0.3 | 0.03 | 550 | 500 | ||||||

| The NEO (Neo) Type offers a Type A dual-purpose device with a glitter finish. This device includes 3 cutting tips and 7 welding tips for enhanced versatility. | 1 Type 2 (Cutter) |

0 | 0.8 | ~10 | 0.3 | 0.03 | 1800 | 375 | 340 | 555(590) | 535 | 470 |

| 1 | 1 | 5~15 | 0.3 | 0.03 | 1800 | 400 | 360 | Blowing Pipe 960 Welding Pipe 200 |

Blowing Pipe 900 Welding Pipe 200 |

Blowing Pipe 570 Welding Pipe 200 |

||

| 2 | 1.3 | 15~25 | 0.3 | 0.03 | 3000 | 485 | 440 | |||||

| 3 | 1.6 | 20~50 | 0.3 | 0.03 | 4500 | 575 | 520 | |||||

| Type 1 (Welder) |

250 | 1.4 | 2.3~2.5 | 0.4 | 0.04 | 275 | 250 | |||||

| 315 | 1.5 | 2.5~3.2 | 0.4 | 0.04 | 350 | 315 | ||||||

| 400 | 1.6 | 3.2~4 | 0.4 | 0.04 | 440 | 400 | ||||||

| 500 | 1.8 | 4.5~5 | 0.4 | 0.04 | 550 | 500 | Cutting Tip 125 Welding Tip 45 |

|||||

| 630 | 2 | 5~6,5 | 0.4 | 0.04 | 695 | 630 | ||||||

| 800 | 2.2 | 6,5~8 | 0.4 | 0.04 | 880 | 800 | ||||||

| 1000 | 2.4 | 8~10 | 0.4 | 0.04 | 1100 | 1000 | ||||||