Japan

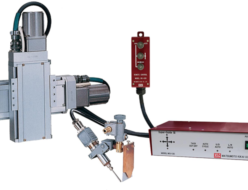

CVJ Shaft Joint Automatic Ultrasonic Flaw Detection System

Made in Japan

Feature:

- This equipment performs 100% inspection of shaft joints of constant velocity joints (CVJ shafts) of automobile parts using ultrasonic flaw detection.

- There are manual type and automatic transfer types, and inspection can be done without setup change just by changing the model, even for a wide variety of products

- .If the joint is friction welded, the center and periphery of the shaft are mainly inspected.

- After flaw detection, water is removed by air blow before being carried out.

Specifications:

1) Target work

- Shape: Shaft & Cup

- Material: Steel

- Dimensions, etc.: Shaft outer diameter Φ20-50mm, length 400mm-600mm

- Work type: No question

2) Flaw detection method and inspection performance

- Flaw detection method: Gap water immersion oblique angle method & 2 probe K scanning method or vertical method

- Target flaw: All-cross-section bonding failure

- Inspection performance: Φ2FBH and peripheral slit

- Processing capacity: 20 to 30 seconds/piece

Related Products

-

Tokyo Ko-on Denpa 2R6-A, 4R6-A Rotary Switch

-

SUGIYASU KGL20HF Platform Stacker

-

DIJET WNMA080404, WNMA080408, WNMA080412 Insert For Cast Iron

-

Gentos GF-116RG Flashlight

-

Matsumoto Kikai WSG-1300/2300 Automatic Groove Tracking Device “Super Guide”

-

Kansai Kogu 1300008210,1300108210,1300209210 Air Hammer Chisel Sheet Smoothing Hammer