Dijet, Japan

DIJET EXSAP Shoulder Extreme

Product Made in Japan

Manufacturer: DIJET INDUSTRIAL CO., LTD

Mode :EXSAP

Indexable tool for high efficient shoulder milling

Line-up

| Cat. No. | Type | Tool Diameter (ΦDc) |

|---|---|---|

| EXSAP | 17 type・Facemill type | Φ50~Φ125 |

| 17 type・Endmill type | Φ25~Φ32 | |

| 17 type・Modular head type | Φ25~Φ40 | |

| 11 type・Facemill type | Φ40~Φ80 | |

| 11 type・Endmill type | Φ16~Φ40 | |

| 11 type・Modular head type | Φ16~Φ40 |

Feature of product

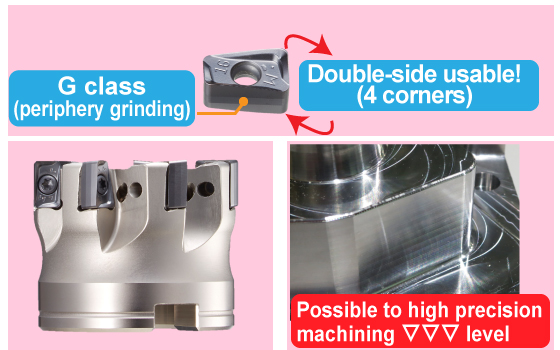

High precision G class periphery grinding inserts can get a long life and beautifully finished surfaces

Insert is double side (4 corners).

High precision G class periphery grinding inserts can get a long life and beautifully finished surfaces.

Because of arc geometry on the periphery cutting edge achieved high precision machining at ▽▽▽ level.

High rigidity insert achieved high precision machining even in large ap machining due to the thick insert

Max.depth of cut (ap)=15mm is possible.

Possible to applicate from roughing process to semi finishing even with large ap cutting

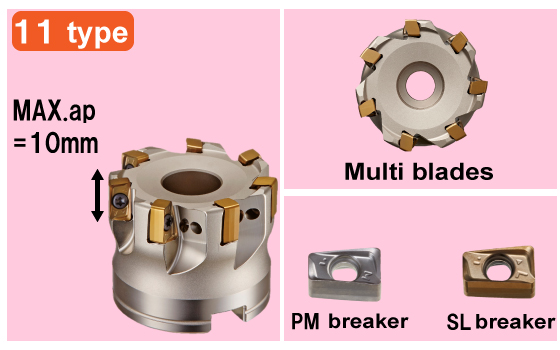

11 type has small-diameter, multi-blade, high-speed, high-precision blades for highly efficient semi-finishing processes

Accuracy of tool dia. with master insert 0〜-0.1 achieves even higher precision semi finishing process.

Superior cutting performance by multi blades with small inserts achieved high efficiency and high speed machining. SL breaker for hard-to-cut materials such as Titanium alloy and Inconel.

FAQ about Indexable tool for shoulder milling

![]() Which type is more suitable for plunging milling, 11 type or 17 type?

Which type is more suitable for plunging milling, 11 type or 17 type?

![]() 17 type is recommended because of the strength of the insert.

17 type is recommended because of the strength of the insert.

Please select 11 type when removal stock is not a lot.