Exen, Preumatic Blaster

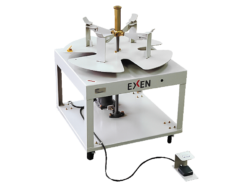

EXEN EDB4-60T Twin Blaster

Products Made In Japan

Manufacturer: EXEN

Model: EDB4-60T

Twin type pneumatic direct blaster

This product is used for the following applications:

- 01.Prevention of blockage in coal storage loader and hopper

- 02.Prevention of blockage in dust hopper for dust collector in waste treatment plant

- 03.Prevention of blockage in dust hopper for dust collector in waste treatment plant

- 04.Elimination of bridging of glass material

- 05.Elimination of sludge incineration ash

Features

Twin type pneumatic direct blaster has one tank and two injection ports. Blasting the compressed air directly into the adhesion or clogging of powder, the product has a strong destruction force like the pneumatic direct blaster and is also excellent in safety. It produces a synergistic effect on the powder that adheres when vibrated. *For the operating principle of air relay knocker, also refer to “Operating principle of flow aid”.

New valve mechanism improving maintenability

For the conventional blaster, once installed in the silo or hopper, it was necessary to replace the product itself when replacing a consumable part. This took lots of hard work because the product may have been installed to a high place. By adopting the new valve mechanism in which the above disadvantage is removed, a consumable part in the valve can be easily replaced at the installation site, which improves the maintenability.

All pressure tanks comply with design standards of class-2 pressure vessel

Like the production series (pneumatic direct blaster and pneumatic twin blaster), the pressure tank for pneumatic filling is designed and manufactured in accordance with the class-2 pressure vessel standards (JIS). Although the above standards are applied to pressure tanks with capacity of 40L or more, EXEN applies the standards to all models (20L to 230L) for customers to use them safely. In consideration of maintenance, the meter is mounted outside to be able to check whether pneumatic filling is sufficient in the pressure tank.

(standard equipment in all models)

Achievement of synergetic effect via two capabilities by twin type one unit

The injection ports located in the right and left of body blasts the air alternately. For a tough blockage, changing the second injection in a different direction than that of the first injection provides a synergetic effect. Generally, the product is installed so that combination of two or more units provides further injection effect, and has a large number of track records in the fresh concrete plant, secondary concrete product plant, plant silo of dam site.

Cost reduction via two capabilities by twin type one unit

One direct blaster has capabilities for two unit, which means that using multiple unit s allows significant cost reduction. The installation const is also reduced because of the number of units. The maintenance cost is also reduced because of the same reason.

Safety first in factory

Accidents have occurred continuously owing to reliance on man-powered work for eliminating blockage in silo. The blockage in silo is caused by an arching phenomenon and balance of contents. An imbalance from man-powered work causes the contents to start flowing, which will result in a large-scale accident. The pneumatic direct blaster is adopted in many sites for the purpose of preventing the above accident causing injury or death.

Variable injection force by pressure regulation

Adoption of mushroom valve method allows an injection force to be adjusted by changing the pressure of supplied air. If there is a request to make replacement for larger or smaller equipment, the issue can be solved by pressure regulation with unnecessary replacement work.

Nitrogen gas can be used

Nitrogen gas can be used for blast air. If the contents are flammable or likely to be exploded, nitrogen gas can be used. The safety measures for explosion proof can be secured by the blaster, which results in cost reduction. This product has a large number of proven track records in the waste disposal plant, etc.

Dedicated nozzles are available as options

Various types of dedicated nozzles are available, which can be chose depending on the situation of adhesion or clogging and installation location.

*For manufacturing of special nozzle with heat resistance of 1000℃ or more, contact EXEN.

Specification

EDB-T

Model Outlet dia.

(inch)Tank capacity

(Liter)Working pressure

(MPa)Available gas Coating Weight

(kg)Outer surface Inner surface EDB2.5-20T 2.5 20 0.3 – 0.7 Compressed air

or

Nitrogen gasEpoxy resin coating 57 EDB2.5-30T 30 58 EDB4-60T 4 60 114 EDB4-130T 130 134 EDB6-230T 6 230 231 (Imperial System)

Model Outlet dia.

(inch)Tank capacity

(Cu. Ft)Working pressure

(PSI)Available gas Coating Weight

(lb)Outer surface Inner surface EDB2.5-20T 2.5 0.71 44 – 102 Compressed air

or

Nitrogen gasEpoxy resin

coating125.7 EDB2.5-30T 1.06 127.9 EDB4-60T 4 2.12 251.3 EDB4-130T 4.59 295.4 EDB6-230T 6 8.12 509.3 * Tanks are designed and manufactured with a maximum working pressure specified to 0.97MPa.

Dimensions, installation, control panel

Product dimensional drawings

Product dimensional table

Model Outlet dia. Total length width Tank size Inlet Eye Bolt A B F L W1 W2 ΦD E G EDB2.5-20T 65 140 4-M16 1161 390 500 216 566 15A

(1/2B)M12 EDB2.5-30T 1152 417 527 267 494 EDB4-60T 100 175 8-M16 1590 494 604 319 712 M16 EDB4-130T 1641 566 676 462 685 EDB6-230T 150 240 8-M20 2155 664 774 512 1011 M20 (Imperial System)

Model Outlet dia. Total length width Tank size Inlet Eye Bolt A B F L W1 W2 ΦD E G EDB2.5-20T 2.6 5.5 4-5/8 3’10” 1’3″ 1’8″ 8.5 1’10” 15A

(1/2B)7/16 EDB2.5-30T 3’9″ 1’4″ 1’9″ 10.5 1’7″ EDB4-60T 3.9 6.9 8-5/8 5’3″ 1’7″ 2’0″ 1’1″ 2’4″ 5/8 EDB4-130T 5’5″ 1’10” 2’3″ 1’6″ 2’3″ EDB6-230T 5.9 9.4 8-3/4 7’1″ 2’2″ 2’6″ 1’8″ 3’4″ 3/4 Kouei is the Official Distributor/Agent of EXEN.

Other items of Exen

Request the quotation for Exen