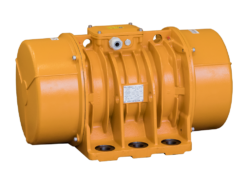

Air Knocker, Exen

EXEN EKE5000 Air Knocker Control Panel For Indoor/Outdoor Use

Products Made In Japan

Manufacturer: EXEN

Model: EKE5000

Knocker control panel supporting three input voltages!

This product is used for the following applications:

- 01Used when the timer operation for the number RKVs to be controlled is required for hopper in the environmental recycling plant

- 02Prevention of blockage in dust hopper for dust collector in waste treatment plant

-

Features

EKE5000 model is a control panel for indoor and outdoor use that can controls the operation interval of air knocker, Mini Mini Blaster, and soft disk blaster and that can operate two lines of A and B with the solenoid valve included. (IP code 44 draining waterproof) The input power voltage is 100VAC to 240VAC. (Input power voltage of 24VDC can be supported: built-to-order product) The timer can be set in wide range of time from 1 second to 99 hours, and the timer display employing LED is easily viewable. In addition to the timer control, the control of the number of times of operations is also possible.

Input power voltage range (100VAC to 240VAC) expanding applications

The product can be adapted to almost all fields because one control panel supports the input power with single-phase 100VAC to 240VAC voltage. The output voltage is the same as the input voltage. (The product supporting the input of 24VDC is a built-to-order product.)

Bright and clear timer display

The timer is displayed in bright and clear LED display, which allows the setting time to be checked even in a dark site.

Easy timer setup

The timer is set by opening the cover and then flipping the switches of second, minute, and hour with a finger to easily set second, minute, and hour to 0.5, 1 to 99 seconds, 1 to 99 minutes, and 1 to 99 hours, respectively.

Number of times of operations can be set

After the interval time of operation is set, the number of times of operations can also be set easily. The setting number is 1 to 99, and infinite. It is convenient that the remaining number of times from start to end is also displayed.

Selection of “Standard” and “Alternation” modes

When using the knockers divided into two lines by use of the port solenoid valve, select “Alternation” mode to perform the alternating operation of two lines of A and B. (the same as the function of knocker control panel HKE series) If only A line is used with the timer setting time long, select “Standard” mode. The product is factory-set to “Alternation” mode.

Simultaneous use of multiple knockers

The number of knockers that can be used (RKV, RKD, and RKVS, under standard piping) by EKE5000 model. 15: 10 sets, 20PA and 30PA: 8 sets, 60PA: 6 sets, 80 and 100PA: 4 sets (simultaneous control per line) (When the relay piping is used, up to 10 knockers can be used per line regardless of model)

IP code 44

With a structure complying with IP code IP44 draining waterproof and dustproof, EKE5000 model can be used both indoors and outdoors. It can be installed to any site where there is a large amount of dust or outdoors.

Operation triggered by signal from external equipment

The use of external contact (a-contact) of terminal block in control panel allows the knocker to start striking upon receiving the hopper opening-closing valve signal or the conveyance line signal, which is convenient to remote operation during automatic control.

Convenient combination of setup of infinite number of times and external signal

After the operation interval time is set in timer setup, if the number of times of operations is set to infinite, the knocker continues operation while external signal is received.

Easy test run

Before the timer is set, it is possible to check whether the relay knocker or blaster installed operates correctly, by setting the power switch on the panel to “Setup” and then pressing “Enter” key.

EKE5000 model: precautions for wiring

“2” and “3” of terminal block are used when the control panel is controlled externally. Use the control panel with a switch is connected between “2” and “3” of terminal block.

Specification

EKE5000

Model Protection

ClassInput Voltage

(V)Timer’s

Set TimeStroke

CycleWorking Pressure

(MPa)Number Of The Units

Can Be OperatedApprox dimensions

(LXWXH)(mm)Weight

(kg)EKE5000 IP44 Single Phase

AC100-240On Setting

0.5sec1-99.

Infinity0.3-0.7 15 10 Units.

20・30PA 8 Units.

40・60PA 6 Units.

80・100 PA 4 Units.

(Per 1 System)450x390x219 13.7 Off Setting

1sec-pphrs(Imperial System)

Model Protection

ClassInput Voltage

(V)Timer’s

Set TimeStroke

CycleWorking Pressure

(PSI)Number Of The Units

Can Be OperatedApprox dimensions

(LXWXH)(inch)Weight

(lb)EKE5000 IP44 Single Phase

AC100-240On Setting

0.5sec1-99.

Infinity44-102 15 10 Units.

20・30PA 8 Units.

40・60PA 6 Units.

80・100 PA 4 Units.

(Per 1 System)17-1/32

x

15-1/64

x

8-5/830.20 Off Setting

1sec-pphrsDimensions, installation, control panel

Product dimensional drawings

EKE5000(Parentheses inch display)