Dam-use Vibrator, Exen

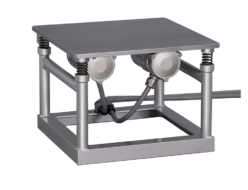

EXEN HIB150HDL VIBACK Front Assembly

Products Made In Japan

Manufacturer: EXEN

Model: HIB150HDL

Best suited for concrete placement in cramped places and sand control dams inaccessible to hydraulic shovels.

This product serves the following applications: Dam concrete placement

Features

Versatile slewing front assembly

We have taken advantage of the know-how accumulated over many years of dam concreting with Vibacks to adoptize the slewing system of the front.

Processes these days require concreting in vertically long, cramped spaces inaccessible with a transverse single-row array of vibrators, along with concreting in the lateral sides of the corners without moving the base machine. The operator can control the slewing of the front, efficiently pouring concrete.

An operationally safer front unit

The hydraulic piping of the front with a vibrator on it is of the manifold type, resulting in a reduced incidence of moving the hydraulic hose around and in a simple, thin shape. A more compact front improves the operator’s field of vision, while increasing safety in slewing the base machine.

Labor-saving

Conventional concreting practices used a handheld vibrator to pour concrete in cramped locations. The Viback front assembly has a powerful hydraulic vibrator that displays great performance. This, together with a slewing frame, saves labor.

(In molds with their backs opposed to each other and other particular locations, a handheld vibrator may be needed. Prudent construction planning is therefore necessary.)

Powerful, safe vibrating compaction

A large hydraulic vibrator with an outer diameter of 150 mm powerfully vibrates and finishes dam concrete as equally strong concrete, effectively managing coarse aggregate (up to 150 mm) and low-slump concrete (0 to 3 mm).

A highly abrasion-resistant vibrator tip

Unlike ordinary concrete used in architectural and civil engineering works, dam concrete is hard and not fluid. During concreting and during the initial contact with rock, the vibrator tip becomes considerably worn.

We make the tip from ductile cast iron and subject it to special treatment, ensuring high durability. (Users can replace the tip alone.)

A damping structure with controlled vibration transmission to the base machine

The unit has a unique dual damping structure where the powerful vibration of the hydraulic vibrator is prevented from reaching the front assembly frame or base machine connections.

Hydraulic circuit

To secure a required frequency for concrete placing, There is a flow control valve which can be easy adjustment.

Hydraulic vibrator for the front assembly

The inner vibrator used is a hydraulic vibrator HIB150HDL.

This special-purpose front assembly machine has been enhanced to ensure applicability in circuit breaker circuits.

*Please note that this unit is no longer compatible with the HIB150HL,which used to be used in conventional Vibacks.

The base machine can be made versatile

Your hydraulic shovel has been used to realize front assembly system for use as a dam concreting machine.

At the end of the concreting, the unit can easily be put back into the backhoe.

Specification

Vibrator Specifications

| Model | Frequency (Hz) | CentrifugalForce (kN) | Maximum use pressure (MPa) | Oil flow rate (L/min) | Head length (dia×length) (mm) | Effecive range (m) | Weight (kg) |

|---|---|---|---|---|---|---|---|

| HIB150HDL | 117~133 | 13.6~17.8 | 20.6 | 14~16 | Φ150×850 | 1.0 | 68 |

(Imperial System)

| Model | Frequency (lbf) | CentrifugalForce (lbf) | Maximum use pressure (PSI) | Oil flow rate (gal/min) | Head length (dia×length) (in×ft) | Effecive range (ft) | Weight (lb) |

|---|---|---|---|---|---|---|---|

| HIB150HDL | 117~133 | 3,057~4,002 | 2,987 | 3.7~4.2 | Φ5.9×2’9″ | 3’3″ | 149 |