Air Knocker, Exen, Japan

EXEN RKV60PA Relay Knocker (Vibe Type)

Products Made In Japan

Manufacturer: EXEN

Model: RKV60PA

Automation of hammer rings eliminates blockages in powders

It has been used in this way

- 01.Sludge fueling equipment To prevent residence in hoppers

- 02.Prevention of dust hopper blockage at garbage disposal sites

- 03.Prevention of blockage of recycled fuel (capsules compressed with wood) supplied hoppers

- 04.Prevention of glass carette storage hopper blockage

- 05.Elimination of blockages in feed silos for livestock

- 06.For promoting silica gel discharge

- 07.Elimination of wall adhesion of fired raw materials

- 08.Dusting off ash adhesion at recycling plants. Promotion of aluminum powder discharge

- 09.Prevention of adhesion in piping at pharmaceutical factories

Features

- The air-type relay knocker (vibe type) is a unique device that eliminates powder adhesion and blockage prevention due to the impact of the piston hitting the base surface with the force of compressed air. In addition, since it can be used only by air supply, it is excellent in safety and economy, and can be used safely without hindrance to powders with the property of sticking when centrilytic force vibration is given.

High strength adoption improves durability

The blow force can be varied by adjusting the supply air pressure.

Relay piping of multiple simultaneous use is possible.

Oil-free, drive-free and eco-friendly

Simple construction and high durability

Large knocker to eliminate blockages

Strike energy graph at RKV-PA/PAR 0.7MPa.

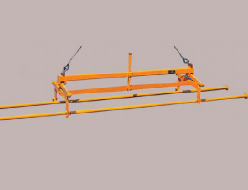

Knocker mounting method

Compact and lightweight for widespread use

Operating principle of relay knocker

1. Compressed air flowing into the knocker is first supplied to the valve chamber, and the umbrella valve is pushed down and stored in the storage chamber.

2. When the three-way valve is activated to exhaust the air in the valve room, compressed air in the storage chamber moves the umbrella valve up.

3. When the umbrella valve moves, compressed air in the storage chamber pushes the piston down and knocks the base surface.

Its impact force eliminates adhesion and blockage of powders.

Specification

Product dimension table

| Model | φA | φC | D | G | H | I | φJ | φK | L | M | M’ | φN | O | P | Tube diameter used |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RKV60PA/PAR | 115 | 138 | 14 | Rp1/8 | 183 | (25) | 15.0 | 110 | 15 | 80 | 120 | 76.0 | Rp3/8 | (196) | φ8Xφ6 |

| RKV80PA/PAR | 146 | 148 | 16 | Rp1/4 | 222 | (28) | 17.0 | 120 | 18 | 90 | 115 | Rp1/2 | (216) | ||

| RKV100PA/PAR | 175 | 208 | 20 | 270 | 21.0 | 170 | 23 | 115 | 135 | 114.3 | Rp3/4 | (308) | |||

| RKV120P | 220 | 235 | 21 | 326 | 17.5 | 198 | 23 | 100 | 120 | 133 | 2-Rp3/4 | (313) |

Installation method

■Tightening torque table (units: N/m)

| Nut size | *M6 | M8 | M10 | M12 | M14 | M16 | M20 | |

|---|---|---|---|---|---|---|---|---|

| Tightening torque | Bottom nut | *4.8 | 10.8 | 20.6 | 35.3 | 56.9 | 84.3 | 167 |

| Top nut | *4.8 | 7.6 | 14.4 | 24.7 | 39.8 | 59.0 | 117 | |

* The figures listed in M6 are the tightening torque of the double nut. Applies to RKV20P.

* The figures listed in M8 to M20 are the tightening torque of hard lock nuts. Applies to non-RKV20P.

* When fixing the main body with the included bolts, spring washers, and hard lock nuts, please protect the tightening torque. If the tightening torque is weak, the nut may loosen due to the impact during operation.

※ For fall prevention, suspend and fix the main body with the attached fall prevention wire and shackle.

Be sure to prevent loosening of the screw with wire, etc. on the screw part of the shackle.

Related Products

-

Matsumoto Kikai MS-180~405 Super Saw for stainless steel

-

MIKI NETSUREN CU-KE Concrete Road Divider Hanging Clamp

-

Aichi WM05C1NS / RM05C1NS SKYTOWER

-

LPL DS-30 Digital Data Stand

-

Watanabe WPMZ-6 Graphical Digital Panel Meter (instantaneous/integrated measurement) – Frequency meter/tachometer

-

Organo HP Micro Filter