Fukuda Seiko, Japan

Fukuda PulseNG Sensors machine protection system PulseNG

Made in Japan

Manufacturer: Fukuda Seiko

Model: PulseNG Sensors machine protection system PulseNG

Features

The range of monitoring systems from the German-based Montronix company offers optimal solutions for various maintenance requirements such as tool and process monitoring, condition diagnostics and machine protection. Combine powerful HMI software with Montronix products to protect your machines.

- Real-time, 24-hour automatic monitoring and machine protection

- Reaction time of less than 1 ms to collision detection

- Advanced threshold control in conjunction with CNC

- Low-speed, high-load collisions can also be monitored

use

- Machining

- Various machine tools

- robot

- Conveying system

- Various equipment components (ball screws, linear guides, bearings)

PulseNG Machine Protection System

From these events that cause serious equipment failures, such as collisions, overloads, abnormal vibrations, imbalances, wear and tear of components、…、 The PulseNG system is here to help.

- Build a real-time, 24-hour automated monitoring and protection system

- We work with CNCs such as FANUC, Mitsubishi, and Siemens

- It is possible to detect not only high-speed collisions but also low-speed, high-load collisions

- Reacts to detected collisions in less than 1 ms: Equipped with output circuitry for NC stop and machine emergency stop

- Force (load, stress) and power sensor options enable simultaneous monitoring of overloads and abnormal vibrations

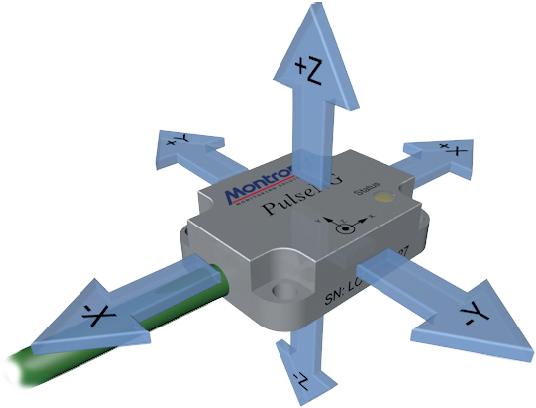

Highly customizable “omnidirectional” monitoring

Example Configurations

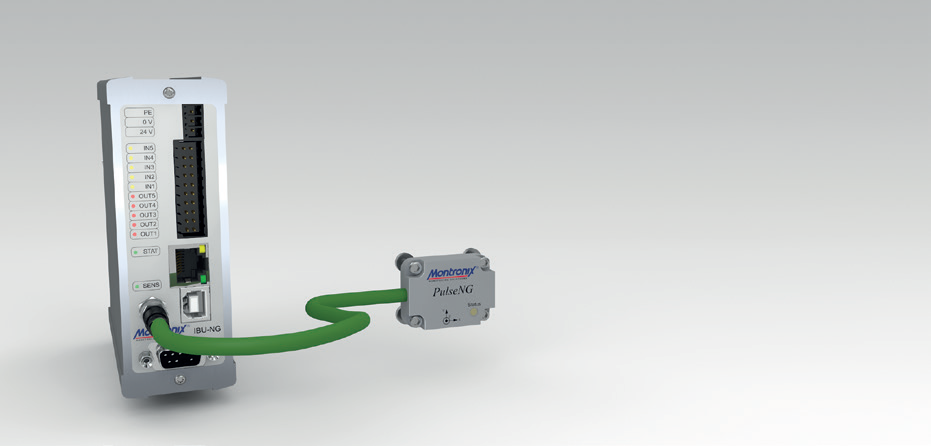

Minimum configuration: Cost-effective monitoring system with a single sensor

IBU-NG (control box) + PulseNG sensor (digital).

This configuration is- High-speed collisions

- 3-axis sensor from all directions

It is possible to monitor.

Advanced Configuration: Example of “Omnidirectional” Monitoring with a Multiplexer

For the basic configuration

- MUX-NG (Multiplexer)

- PulseNG M12 Sensor (Space-Saving Digital 3-Axis Accelerometer/Vibration Meter)

- StrainLink Displacement Sensor x2

- SLA-NG (Displacement Sensor Amplifier)

Multi-monitoring configuration with the addition of.

- At the same time monitor the high-speed collision of two different parts

- Collision of low-speed, high-load (high stress) caused by displacement sensors and abnormal deformation of machine workpieces due to this collision

Also detected. The MUX-NG multiplexer comprehensively monitors collisions between high-speed and low-speed collisions.

Protect a wide range of applications!

- Machining

- lathe

- grinder

- Drilling Machine/Milling Machine

- robot

- Conveying system

- Various equipment components (linear parts such as ball screws and linear guides, bearings, etc.)

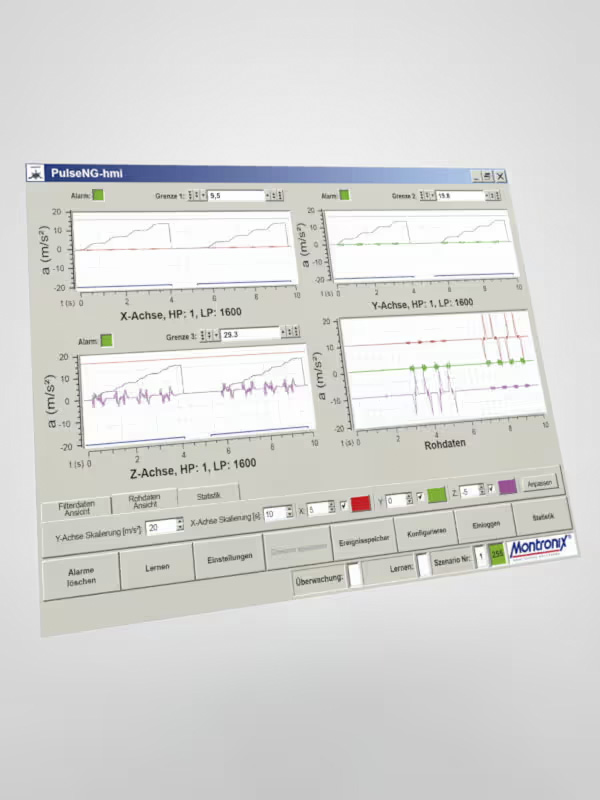

Dedicated software PulseNG-hmi

Software for system configuration and real-time monitoring.

- High-frequency real-time monitoring of 3000sps per axis

- Powerful event logging

- Manager panel with flexible threshold control settings

- Microsoft Windows: Compatible with XP, VISTA, 7, 8, 10 (can be installed on some Linux distributions)

Main Component Specifications

IBU-NG (Control Box)

Dimensions (HxWxD) Approx. 121 x 42 x 120 mm weight about 370 g Degree of protection IP40 Reaction speed to collisions ≤ 1 ms Operating humidity 0% – 95% (non-condensing) Power supply voltage 18-30 V DC