Fukudaco, Japan

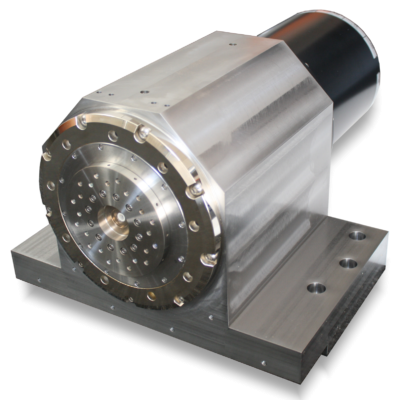

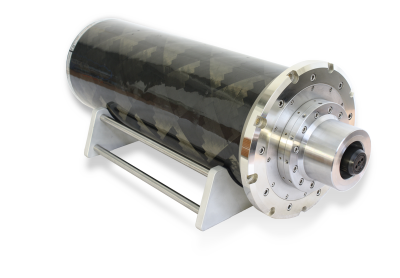

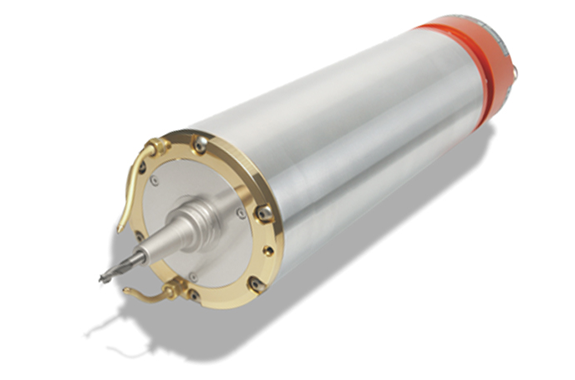

Fukudaco Air Bearing Spindle

Manufacturer: Fukudaco

Overview

Combining a minimal air gap and a wide bearing area results in high-speed rotation, high rotational accuracy, and high rigidity.

Applications

- Micromachining tool spindles (for optical components, LEDs, lighting, and precision molds)

- Precision machining worked

Features

- High-speed rotation

- Excellent rotational accuracy

- Superior stability

- High rigidity

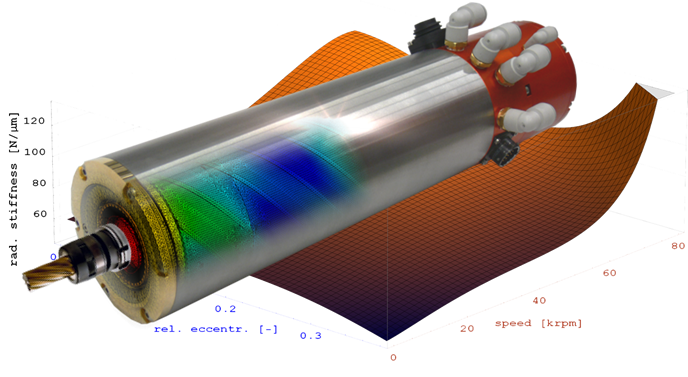

Achieve Ultra-High Precision Machining Unattainable with Rolling Bearings

We deliver high-precision air-bearing spindles with rigidity equal to or greater than conventional rolling-bearing spindles. This is made possible through our proprietary hydrostatic air-bearing technology, various analytical methods utilizing Computational Fluid Dynamics (CFD), and Finite Element Analysis (FEA). These methods and our patented in-house developments enable us to achieve ultra-high precision machining.

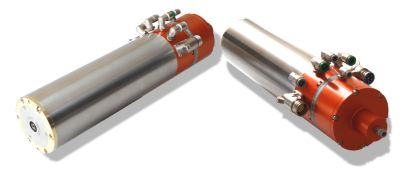

Tool spindle

| Tool Interface | Model |

|---|---|

| HSK-E20 | ASDxxxH20A, UASDxxxH20A |

| HSK-E25 | ASDxxxH25, ASDxxxH25A, UASDxxxH25, UASDxxxH25A |

| HSK-E32 | UASD060H32, UASD060H32A |

| HSK-E40 | UASD060H40 |

| Collet Type | ASDxxxCx, UASDxxxCx |

| HSK-C63 | ASD010PH63M |

HSK-E20

(U)ASDxxxH20A

(U)ASDxxxH20A

Main basic specifications:

| Model | (U)ASDxxxH20A |

|---|---|

| Tool Interface | HSK-E20 |

| Tool change | Automatic, air supply |

| Housing Body Diameter | φ80 mm |

| Motor Type | Brushless DC Motor |

| encoder | 1 Vss SinCos |

| Static taper runout accuracy | < 0.1 μm |

| Shaft Error Motion | < 40nm to 55nm |

| Main Applications | Cutting, internal grinding, drilling |

Available options

| Air Bearing Supply Pressure | ・Standard pressure (0.6 to 1.0 MPa) ・High pressure (2.0 to 3.0 MPa) |

| Connector/joint position | – Axial direction (rear of spindle) |

| Maximum RPM | ・120,000 min -1 ・150,000 min -1 |

| Motor Specifications | ・200 V, high torque (0.22 Nm) ・400 V, high torque (0.22 Nm) ・200 V, high precision slotless (0.13 Nm) |

Specification comparison based on supply pressure and maximum rotation speed

| Standard pressure (0.6 to 1.0 MPa) ASD-H20A | High pressure (2.0 to 3.0 MPa) UASD-H20A | |||

|---|---|---|---|---|

| Maximum rotation speed (min -1 ) | 120,000 | 150,000 | 120,000 | 150,000 |

| Output (kW) High torque motor | 2.5 | 2.8 | 2.5 | 2.8 |

| Output (kW) High-precision motor | 1.6 | 1.9 | 1.6 | 1.9 |

| Radial load capacity (N) | 160 to 200 | 190 | 280~310 | 580 |

| Axial load capacity (N) | 240 | 230 | 650 | 630 |

| Radial stiffness (N/μm) | 16 | 20 | 24 | 38 |

| Axial rigidity (N/μm) | 21 | 25 | 30 | 45 |

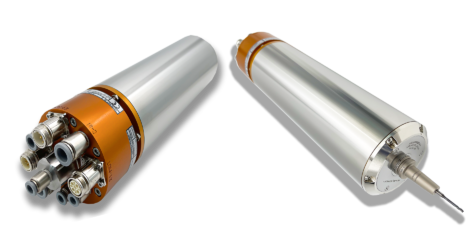

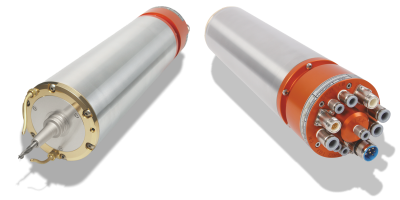

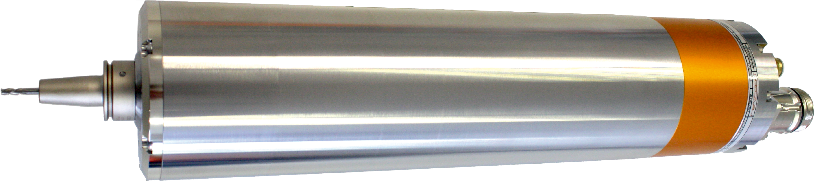

HSK-E25

Main basic specifications:

| Model | (U)ASDxxxH25, (U)ASDxxxH25A |

|---|---|

| Tool Interface | HSK-E25 |

| Tool change | Automatic, air supply |

| Housing Body Diameter | φ100 mm |

| Motor Type | Brushless DC Motor |

| encoder | 1 Vss SinCos |

| Static taper runout accuracy | < 0.1 μm |

| Shaft Error Motion | < 30 nm |

| Main Applications | Cutting, internal grinding, drilling |

Available options

| Air Bearing Supply Pressure | ・Standard pressure (0.6 to 1.0 MPa) ・High pressure (2.0 to 3.0 MPa) |

| Connector/joint position | ・Radial direction ・Axial direction (rear of the spindle) |

| Maximum RPM | ・60,000 min -1 ・80,000 min- 1 ・90,000 min -1 |

| Motor Specifications | ・208 V, high torque (0.7 Nm) ・400 V, high torque (0.7 Nm) ・208 V, high precision slotless (0.33 Nm) ・400 V, high precision slotless (0.33 Nm) |

Specification comparison based on supply pressure and maximum rotation speed

| Standard pressure (0.6 to 1.0 MPa) ASD-H25, ASD-H25A | High pressure (2.0 to 3.0 MPa) UASD-H25, UASD-H25A | |||||

|---|---|---|---|---|---|---|

| Maximum rotation speed (min -1 ) | 60,000 | 80,000 | 90,000 | 60,000 | 80,000 | 90,000 |

| Output (kW) High torque motor | 4.7 | 5.3 | 4.8 | 4.7 | 5.3 | 4.8 |

| Output (kW) High-precision motor | 1.9 | 2.5 | 2.8 | 1.9 | 2.5 | 2.8 |

| Radial load capacity (N) | 300 | 260 | 220 | 900 | 800 | 750 |

| Axial load capacity (N) | 550 | 500 | 450 | 1,300 | 1,250 | 1,200 |

| Radial stiffness (N/μm) | 40 | 25 | 20 | 70 | 50 | 35 |

| Axial rigidity (N/μm) | 65 | 45 | 35 | 150 | 120 | 80 |

HSK-E32

Main basic specifications:

| Model | UASD060H32, UASD060H32A |

|---|---|

| Tool Interface | HSK-E32 |

| Tool change | Automatic, air supply |

| Housing Body Diameter | φ100 mm |

| Motor Type | Brushless DC Motor |

| Maximum RPM | 60,000 min -1 |

| output | 4.2 kW |

| torque | 0.7 Nm |

| encoder | 1 Vss SinCos |

| Static taper runout accuracy | < 0.1 μm |

| Shaft Error Motion | < 30 nm |

| Air Bearing Supply Pressure | 2.0 to 3.0 MPa |

| Radial Load Capacity | 900 N |

| Axial load capacity | 1,300 N |

| Radial Stiffness | 70 N/μm |

| Axial rigidity | 150 N/μm |

| Main Applications | Cutting, internal grinding, drilling |

Available options

| Connector/joint position | ・Radial direction ・Axial direction (rear of the spindle) |

| Motor Specifications | ・208 V, high torque (0.7 Nm) ・400 V, high torque (0.7 Nm) |

HSK-E40

Main basic specifications:

| Model | UASD-H40 |

|---|---|

| Tool Interface | HSK-E40 |

| Tool change | Automatic, air supply |

| Housing Body Diameter | φ120 mm |

| Motor Type | Brushless DC Motor |

| Maximum RPM | 60,000 min -1 |

| output | 4.2 kW |

| torque | 0.7 Nm |

| encoder | 1 Vss SinCos |

| Static taper runout accuracy | < 0.1 μm |

| Shaft Error Motion | < 30 nm |

| Air Bearing Supply Pressure | 4.0 to 6.0 MPa |

| Main Applications | Cutting, internal grinding, drilling |

Collet type

Main basic specifications:

| Model | ASDxxxCx, UASDxxxCx |

|---|---|

| Tool Interface | Collet type (φ3mm, 4mm, 6mm, 1/8″, 1/4″) |

| Tool change | Automatic, air supply |

| Housing Body Diameter | φ100 mm |

| Motor Type | Brushless DC Motor |

| encoder | 1 Vss SinCos |

| Static taper runout accuracy | < 0.1 μm |

| Shaft Error Motion | < 30 nm |

| Main Applications | Cutting, internal grinding, drilling |

Available options

| Air Bearing Supply Pressure | ・Standard pressure (0.6 to 1.0 MPa) ・High pressure (2.0 to 3.0 MPa) |

| Maximum RPM | ・60,000 min -1 ・80,000 min- 1 ・100,000 min -1 |

| Motor Specifications | ・208 V, high torque (0.7 Nm) ・400 V, high torque (0.7 Nm) ・208 V, high precision slotless (0.33 Nm) ・400 V, high precision slotless (0.33 Nm) |

HSK-C63

Main basic specifications:

| Model | ASD-PH63M |

|---|---|

| Tool Interface | HSK-C63 |

| Tool change | Manual |

| Housing Body Diameter | φ175 mm |

| Motor Type | Brushless DC Motor |

| Maximum RPM | 10,000 min -1 |

| Static taper runout accuracy | < 0.1 μm |

| Shaft Error Motion | < 15 nm |

| Air Bearing Supply Pressure | 0.6 to 1.0 MPa |

| Radial Load Capacity | 1,800 N |

| Axial load capacity | 2,500 N |

| Radial Stiffness | 180 N/μm |

| Axial rigidity | 250 N/μm |

| Main Applications | Cutting, internal grinding, external grinding |

Available options

| Motor Specifications | ・400 V, high torque (13.5 Nm) ・400 V, high precision (6.5 Nm) |

| Encoder (Axial Mode) | Standard: Optical, Incremental (1 Vss Sin/Cos, 11840) Optional: Absolute , BISS-C (18/26/32-bit) , Mitsubishi-2/4 (23/27-bit) , Fanuc (23/27-bit) , Drive-CliQ (26/29-bit) |

| Encoder (Spindle Mode) | GMR sensor, increment (1 Vss Sin/Cos, 253) *Not available if absolute encoder in axis mode is selected |

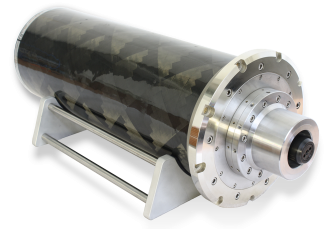

Work head spindle

Main basic specifications:

| Model | ASD-Px |

|---|---|

| Tip Shape | Flat end surface φ120mm |

| Housing Body Diameter | φ175 mm |

| Motor Type | Brushless DC Motor |

| Maximum RPM | 10,000 min -1 |

| Static taper runout accuracy | < 0.1 μm |

| Shaft Error Motion | < 15 nm |

| Air Bearing Supply Pressure | 0.6 to 1.0 MPa |

| Radial Load Capacity | 1,800 N |

| Axial load capacity | 2,500 N |

| Radial Stiffness | 180 N/μm |

| Axial rigidity | 250 N/μm |

| Main Applications | Work heads, turning, shafts, fluctuating |

Available options

| Tip Shape | Standard: Flat end face φ120mm Option : Vacuum chuck (φ150-200mm) HSK-C63 (spindle model number is ASD-PH63M) |

| Motor Specifications | ・400 V, high torque (13.5 Nm) ・400 V, high precision (6.5 Nm) |

| encoder | Standard: Optical, Incremental (1 Vss Sin/Cos, 11840) Optional: Absolute , BISS-C (18/26/32-bit) , Mitsubishi-2/4 (23/27-bit) , Fanuc (23/27-bit) , Drive-CliQ (26/29-bit) |

| Encoder (Spindle Mode) | GMR sensor, increment (1 Vss Sin/Cos, 253) *Not available if absolute encoder in axis mode is selected |

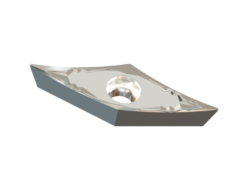

Ultra-precision HSK tool holder

To maximize the capabilities of Levicron’s ultra-precise HSK spindles, the tool holders must be as ultra-precise and highly balanced as the spindles. This is because ordinary tool holders available on the market cannot achieve nano-level precision. Levicron has

developed ultra-precise shrink-fit tool holders through special manufacturing and balancing processes. By combining these tool holders with Levicron’s HSK spindles, you can obtain the following characteristics:

| Tool Interface | HSK-E (DIN 69893-E) 25, 32, 40 |

| Tool fixing method | Shrink fitting |

| Shank diameter (mm) | 8mm, 6mm, 4mm, 3mm (3mm is HSK-E25, -E32 only) |

| Shank diameter (inch) | 1/4″, 1/8″ (HSK-E25 only) |

| Static runout accuracy | < 0.8 μm |

| Balance Grade | G0.3 mm/s@60,000 min -1 |

| Repeatability (axial, radial) | < 0.2 μm |