Fukudaco, Japan

Fukudaco Coolant-Driven Spindle ColibriJet

Manufacturer: Fukudaco

Existing spindles transform into high-speed spindles.

Improve production efficiency without introducing new machinery.

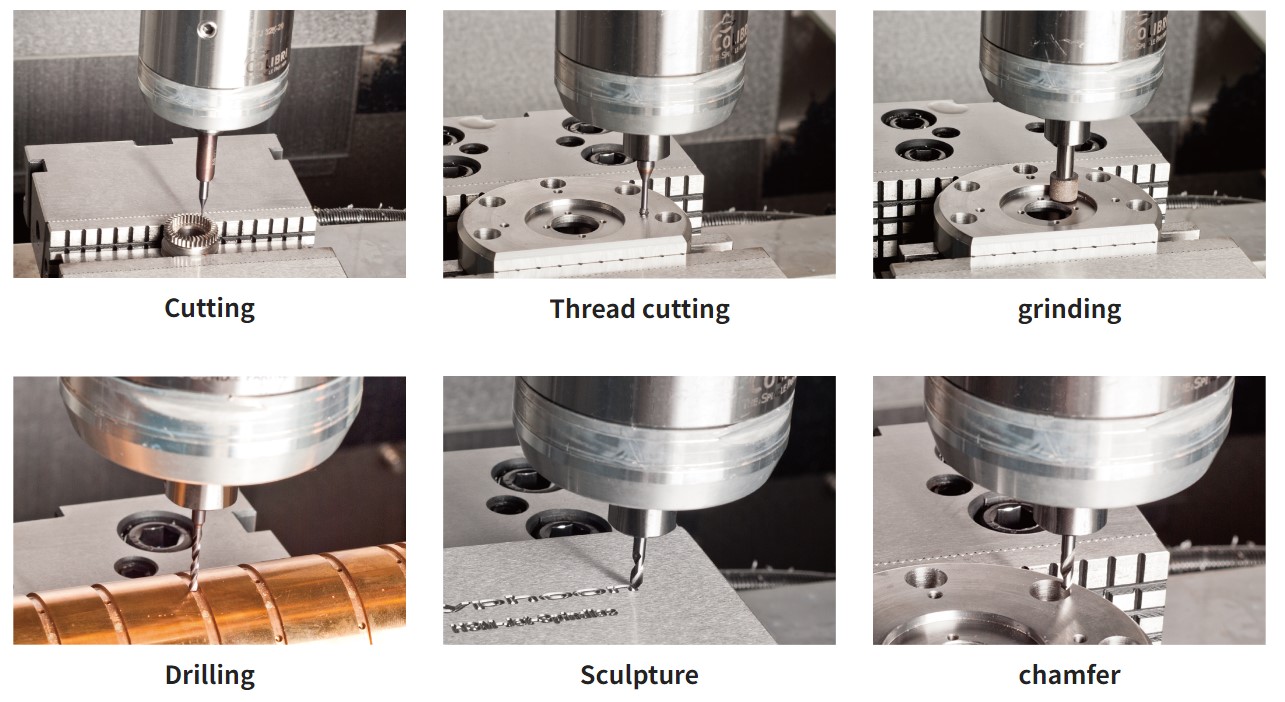

Applications

High-speed rotation for spindles in existing machines

Finishing processes (cutting, drilling, engraving, chamfering, etc.)

Features

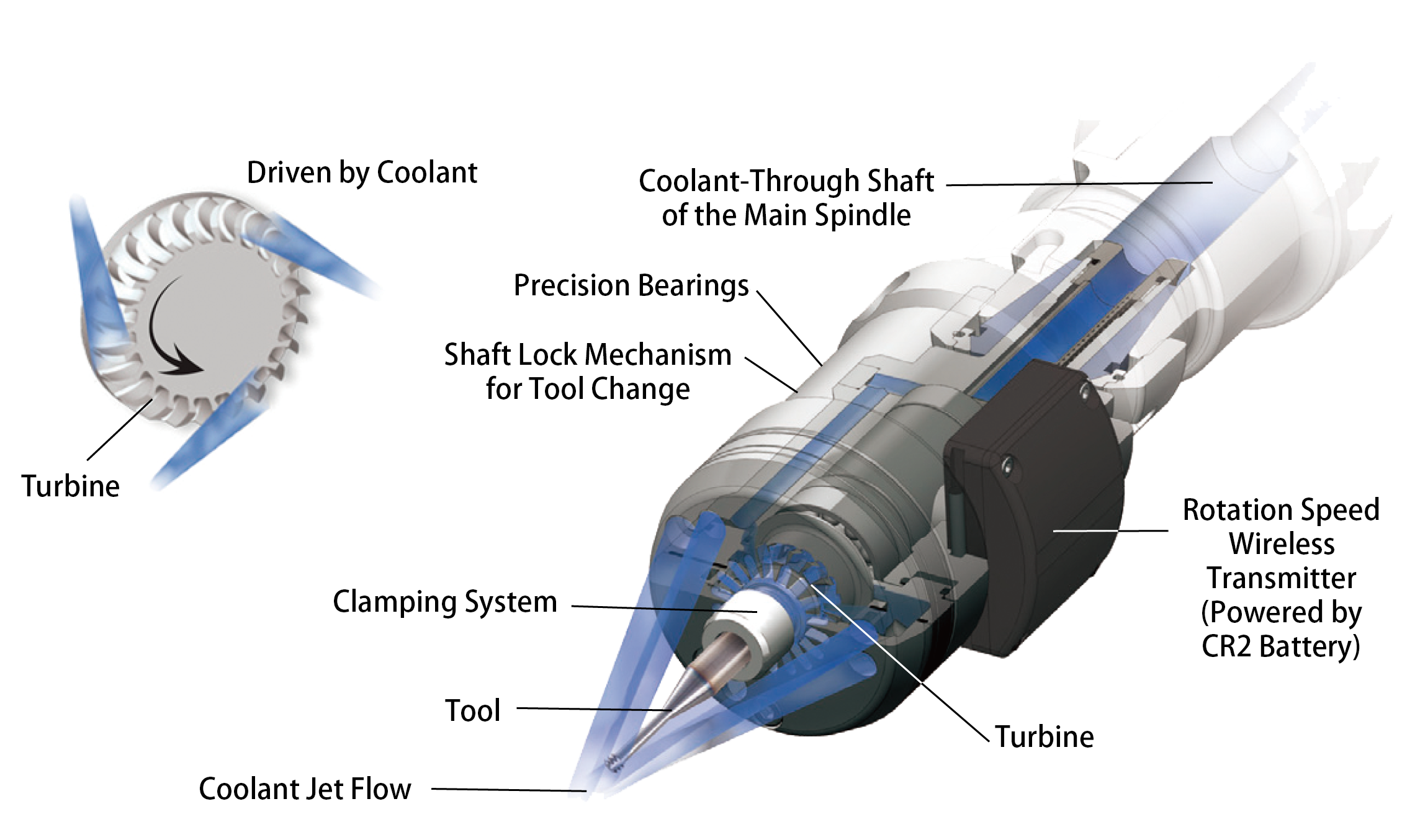

Attaches to the tip of a center-through spindle like a tool holder

Operating speed range: 35,000 rpm to 55,000 rpm or 25,000 rpm to 50,000 rpm

Coolant pressure: 2 MPa to 4 MPa or 4 MPa to 7 MPa

Compatible with various tool interfacesReal-time speed monitoring

Overview of Coolant-Driven Jet Spindles

ColibriJet uses coolant supplied by a machine with a center-through coolant function at a pressure of 2-4 MPa to spin its internal turbine up to 55,000 rpm. This boosts production efficiency without the need for new machinery.

The spindle rotates using the flow of coolant.

Recommended for finishing and semi-finishing processes.

Easily attachable to standard existing machines.

Reduces machining time with high-speed rotation.

Upgrades existing machinery.

Compatible with various tool interfaces

Specifications of the ColibriJet Spindle

GJET |  HPC | |

|---|---|---|

| Operating pressure [MPa] *1 | 2–4 | 1.5–7 |

| Flow rate [Nl/min] *1 | 10–20 | min.12 |

| Rotation speed [min -1 ] *2 | 35,000 – 55,000 | 20,000 – 45,000 |

| Recommended tool diameter (drill) [mm] | ∅0.5 to 2.0 | ∅0.5 to 3.0 |

| Recommended tool diameter (end mill) [mm] | ∅1.5 to 3.5 | ∅1.0 to 4.0 |

| Maximum tool shank diameter [mm] | ∅7.0 | ∅7.0 |

1 The pressure at the inlet supplies the coolant to the ColibriJet spindle.

2 Varies depending on the pressure and viscosity of the coolant.

Compatible Tool Interfaces Examples

In addition to the examples listed below, various other tool interfaces are also supported.

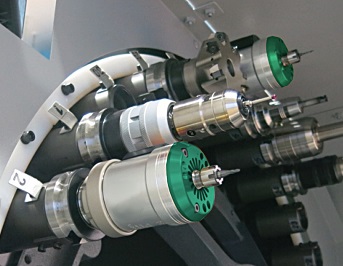

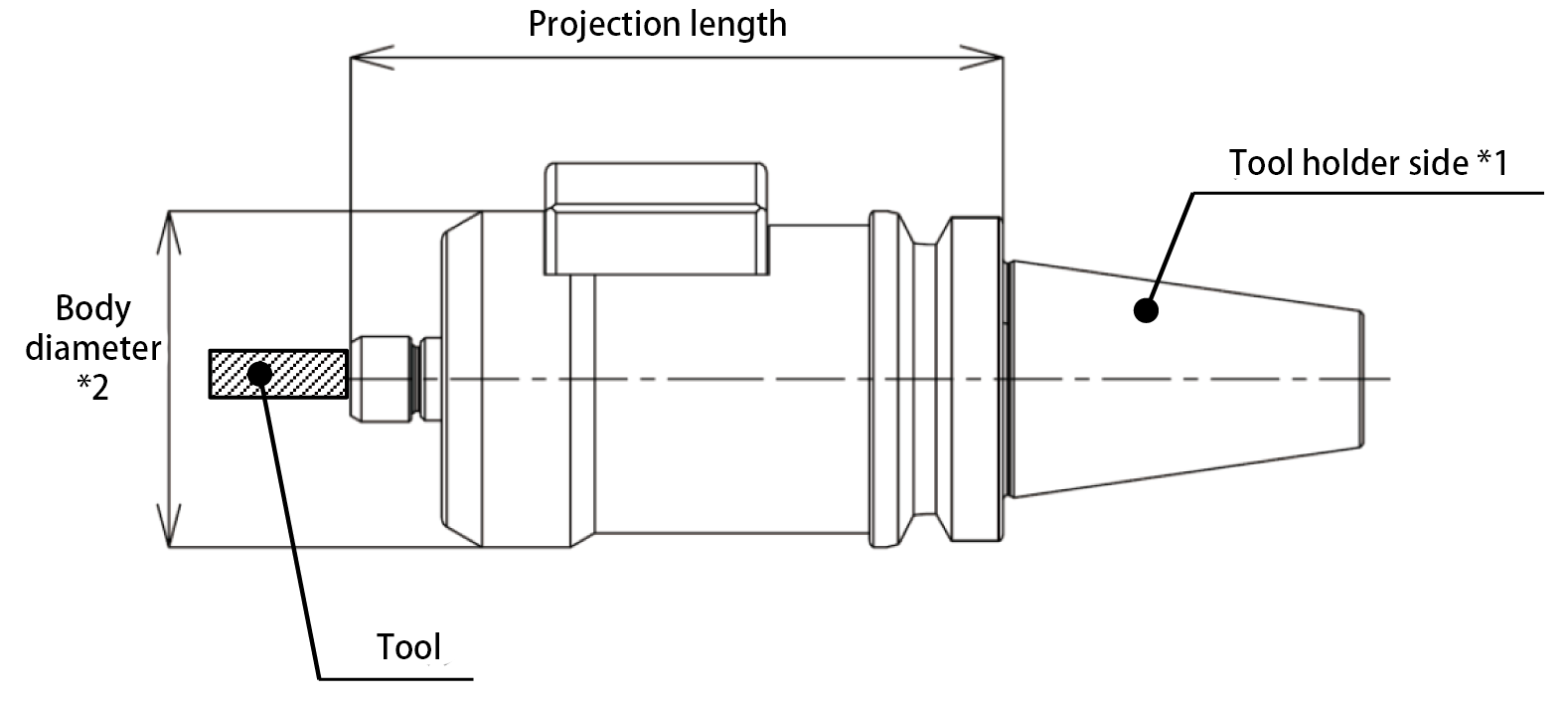

Compact Design and Tool Magazine Compatibility

The ColibriJet spindle’s compact body allows for easy mounting in tool magazines. It is compatible with various tool interfaces such as BT40 and HSK-A63. Utilizing these interfaces, the ColibriJet spindle can be mounted in the tool magazine and automatically attached to the main spindle via automatic tool change (ATC).

Due to its compact body, it can be mounted on the tool magazine.

The ColibriJet spindle is compatible with various tool interfaces, such as BT40 and HSK-A63.

By using the interface, the ColibriJet spindle can be mounted on the tool magazine and attached to the main spindle through automatic tool change (ATC).

Application examples

Lineup

The spindle models in the table below can be selected from a combination of the series name and the main spindle interface name.

TJS – Series – Type

Series: GJET or HPC

Type: Main spindle interface

| Series | Model | Spindle side*1 interface | Overhang length [mm] | Body diameter*2[mm] | Weight [kg] |

|---|---|---|---|---|---|

GJET | TJS-GJET-ER32 | ER32 | 109 | ∅63 | 1.3 |

| TJS-GJET-BT30 | BT30 | 139 | ∅63 | 1.6 | |

| TJS-GJET-BT40 | BT40 | 122 | ∅63 | 1.8 | |

| TJS-GJET-HSK A40 | HSK-A40 | 144 | ∅63 | 1.4 | |

| TJS-GJET-HSK A63 | HSK-A63 | 141 | ∅63 | 1.8 | |

| TJS-GJET-ST20 | Straight ∅20 | 115 | ∅63 | 1.2 | |

| TJS-GJET-C5 | PSC-C5 | 129 | ∅63 | 1.5 | |

| TJS-GJET-C6 | PSC-C6 | 119 | ∅63 | 1.6 | |

| TJS-GJET-CAT40 | CAT40 | 141 | ∅63 | 2 | |

HPC | TJS-HPC-ER32 | ER32 | 116 | ∅80 | 1.7 |

| TJS-HPC-BT40 | BT40 | 115 | ∅80 | 1.9 | |

| TJS-HPC-HSK A63 | HSK-A63 | 138 | ∅80 | 2 | |

| TJS-HPC-ST20 | Straight ∅20 | 112 | ∅80 | 1.5 | |

| TJS-HPC-C6 | PSC-C6 | 124 | ∅80 | 2 | |

| TJS-HPC-CAT40 | CAT40 | 135 | ∅80 | 2.3 |

1 Please contact us for tool interfaces not listed.

2 Dimensions do not include the RPM transmitter.

Lineup (mainly for lathes)

The TR type can be selected for multitasking machines, turret lathes, etc.

The TR type can be used by separately installing a holder that matches the interface on the machine side.

TJS – Series – TR – RC

Series: GJET or HPC

Usage example: VDI40

Usage example: VDI40

| Series | Model | Spindle side*1 interface | Body diameter*2[mm] | Weight*3[kg] |

|---|---|---|---|---|

GJET | TJS-GJET-TR-RC | holder | ∅63 | 0.7 |

HPC | TJS-HPC-TR-RC | holder | ∅80 | 0.8 |

1. Please get in touch with us for details on the holder attachment.

2. Dimensions do not include the wireless transmitter and holder.

3. Weight does not include the holder.

Main unit accessories

Accessories

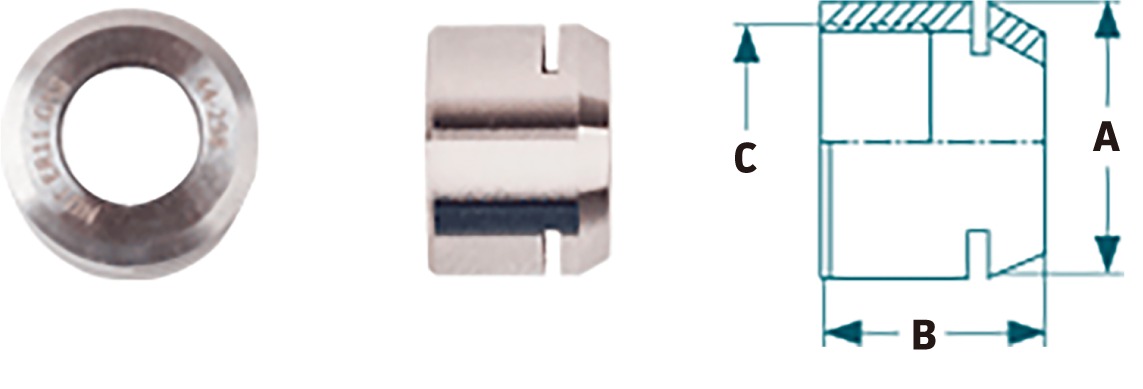

ER11 Collet Nut

| A | ∅16 mm |

|---|---|

| B | 11.5 mm |

| C | M13 x 0.75 |

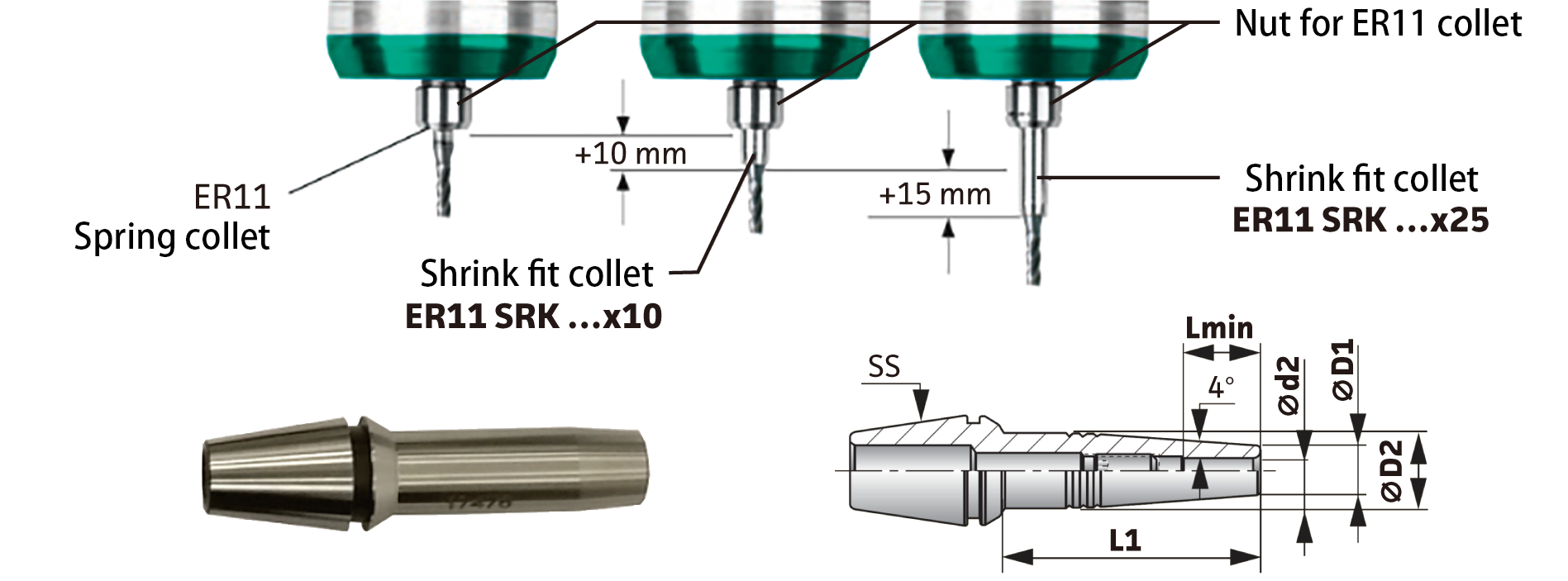

Shrink fit collet

Unit: mm

| Size | d2 | L1 | Lmin | D1 | D2 |

|---|---|---|---|---|---|

| ER11 SRK 3×10 | 3 | 10 | 9.5 | 7.6 | 8.5 |

| ER11 SRK 3×25 | 3 | 25 | 11.5 | 7.6 | 8.5 |

| ER11 SRK 4×10 | 4 | 10 | 9.5 | 7.6 | 8.5 |

| ER11 SRK 4×25 | 4 | 25 | 11.5 | 7.6 | 8.5 |

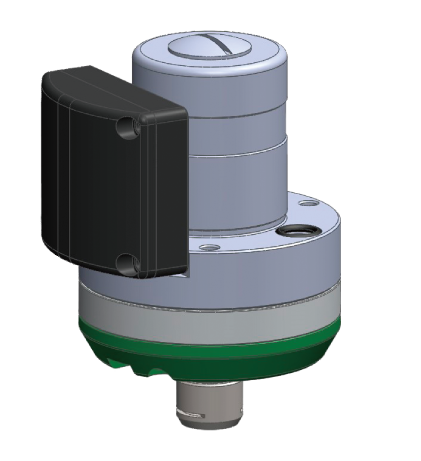

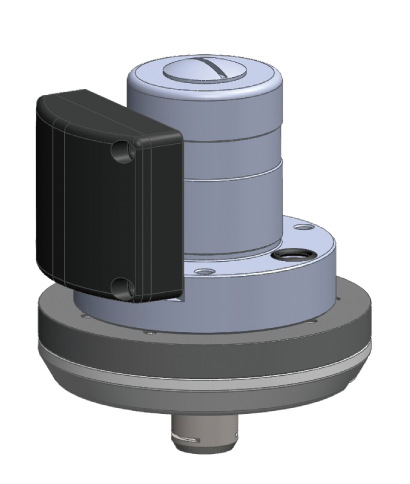

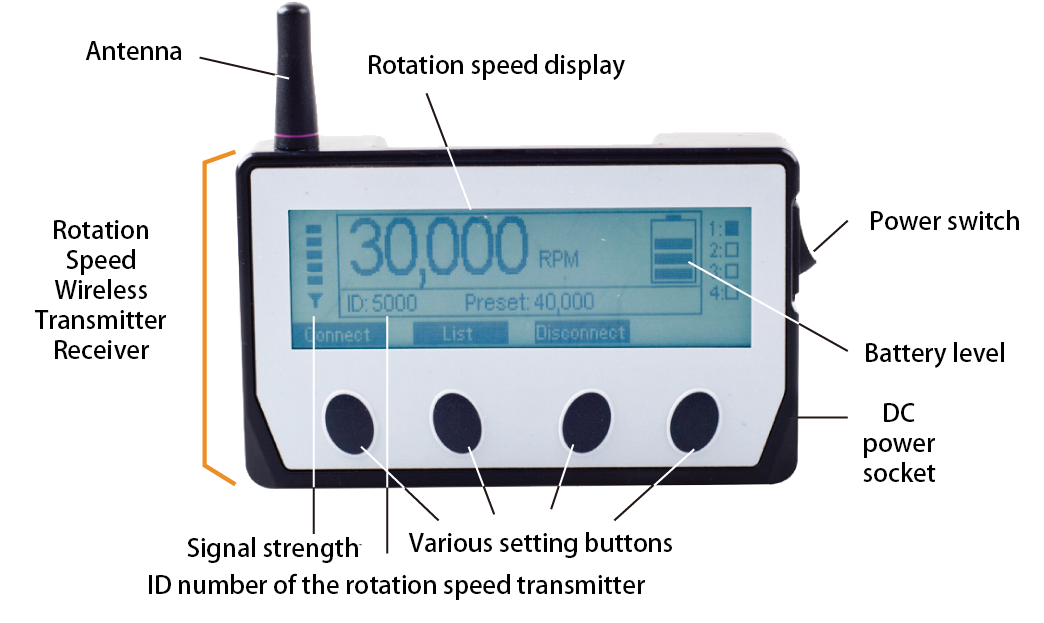

RPM display

Receiver for spindle rotation speed wireless transmitter

Displays rotation speed in real-time through communication

Also displays battery level and signal strength

Can register up to 127 sensor IDs

Only displays spindles that are currently rotating on the display screen

Power supply: AC 100V to 240V