Fukudaco, Japan

Fukudaco Forsheda V-Ring

Manufacturer: Fukudaco

Overview

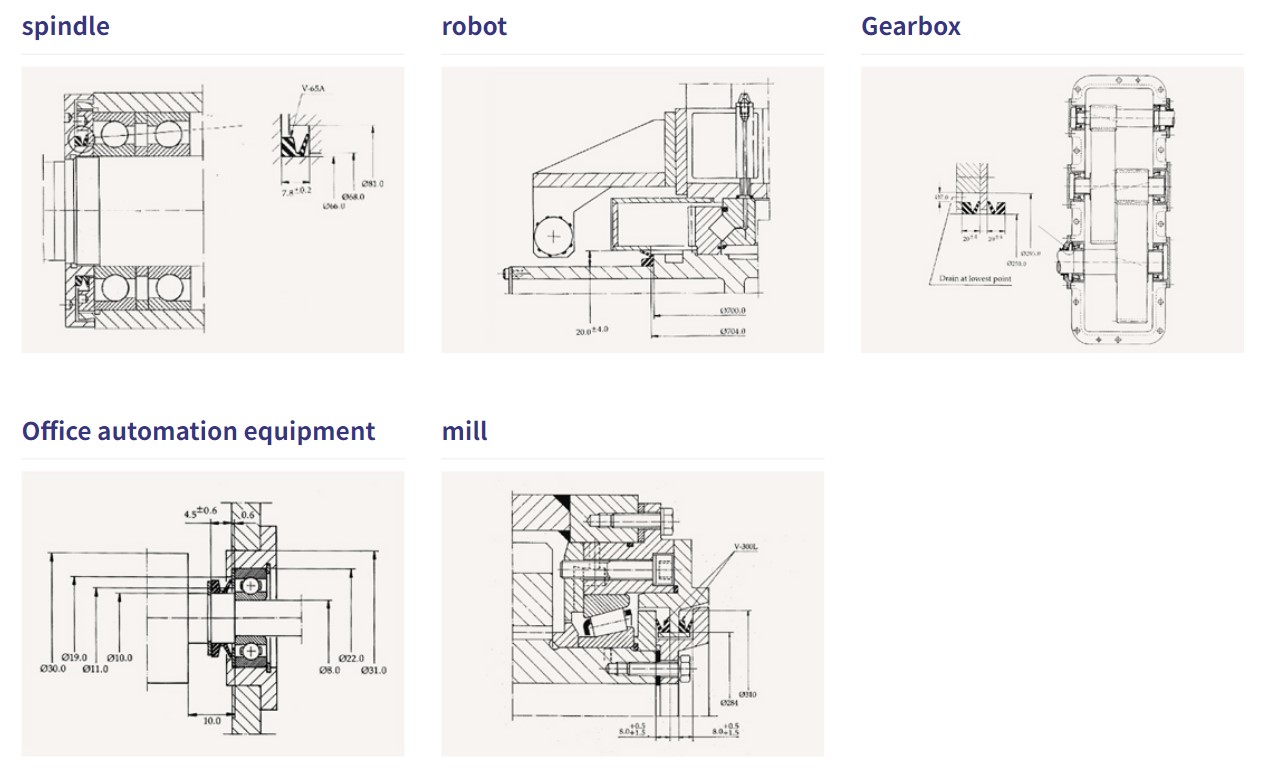

Applications

- Rotating equipment such as motors and pumps

- Rotating parts of large machinery (wind turbines, paper machines, steel manufacturing machines, and others)

Features

- Accommodates a wide range of shaft diameters and follows shaft misalignment and eccentricity

- Minimizes power loss and frictional heat generation

- Easy to install

Available in various cross-sectional shapes and materials (Nitrile rubber, Fluoro rubber, etc.).

Forsheda V-Ring

Be original

The Forsheda V-Ring is a rubber seal for rotating shafts developed by Forsheda AB of Sweden in the 1960s.

With over 50 years of history, the Forsheda V-Ring remains widely used in a variety of applications around the world today.

The unique shape and function of the Forsheda V-Ring allow it to retain grease in a wide variety of bearings while preventing the ingress of dirt, dust, water, and mixtures thereof. It is also used as a secondary seal when other seals are unable to perform their original sealing function in harsh environments.

Features of Special Machining

- Sealing Performance: Ensures effective sealing.

- Compliance with Axial Shaft Runout: Follows axial shaft movement.

- Stable Lip Contact Surface Pressure: Maintains consistent contact pressure.

- Long Lifespan: Durable design for extended use.

Material Properties

- Ozone Resistance: Withstands exposure to ozone.

- Wear Resistance: Highly resistant to wear and tear.

- Wide Range of Materials: Available in NBR, FKM, CR, HNBR, and EPDM.

- Low Permanent Compression Set: Retains shape and function over time.

- Versatile Applications: Suitable for various applications.

Specifications

- Available Sizes: Ranges from φ1.5mm to φ20m.

- Variety of Types: 8 different types available.

- Original Brand: Over 50 years of proven track record.

- Reliability: Trusted performance.

- Trademark Registration: 1309002.

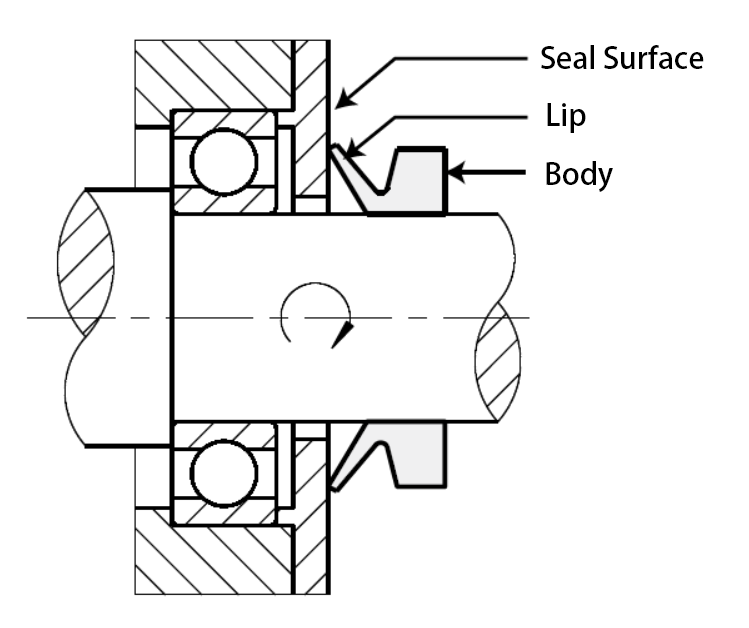

Features and Operating Principles

The Forsheda V-ring is a rubber seal made from a single material without the use of metal or fiber reinforcements.

It is easy to install and is typically stretched and mounted onto the shaft. It can be installed over large components such as flanges or pulleys. The Forsheda V-ring is secured to the shaft by the elastic tension of the rubber.

The operating principle is that when the shaft rotates, the V-ring rotates with it, acting as a face seal against a stationary counterface. The sealing surface can be a housing, washer, bearing end face, or the metal case of an unmarked oil seal.

The flexible lip of the V-ring provides excellent sealing performance with minimal contact pressure against the sealing surface. The installation width can be adjusted for dry operation. Additionally, the flexible lip adapts to shaft runout and eccentricity.

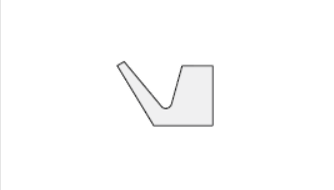

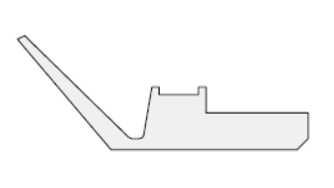

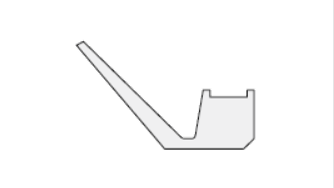

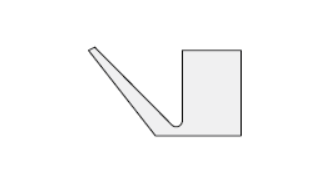

Type

| A | S | L | LX | RM | RME | AX |

|---|---|---|---|---|---|---|

| Standard goods | Made-to-order products | |||||

|

|

|

|

|

|

|

| Φ2.7mm to Φ2,010mm | Φ4.5mm to Φ210mm | Φ105mm to Φ2,025mm | Φ135mm to Φ2,025mm | Φ300mm to Φ2,010mm | Φ300mm to Φ2,010mm | Φ200mm to Φ2,020mm |

| Highly versatile standard-type | Allows for firm attachment to tapered, wide-body shafts | Compact design with a small cross-sectional area | Compact design with a very small cross-sectional area | It is a heavy-duty seal for large-diameter, high-speed applications in steel mills and paper mills, and is also used as a secondary seal in heavy-duty applications involving water and contaminants. | ||

Material

The most commonly used material is Nitrile Rubber (NBR510), which possesses excellent overall properties. For applications where temperatures exceed 100°C or where sealing corrosive fluids, use Fluoro Rubber (FKM907/900). Forsheda V-rings can be selected from a wide range of materials.

To select the optimal material, consider the following conditions:

- Chemical Resistance

- Temperature Resistance (both low and high temperatures)

- Weather and Ozone Resistance

- Wear Resistance

- Low Friction

- Elasticity

- Low Permanent Compression Set

Example of use of Forsheda V-Ring

In addition to the standard A, S, and L types, LX, AX, RM, and RME types can also be used with a variety of equipment.