Fukudaco, Japan

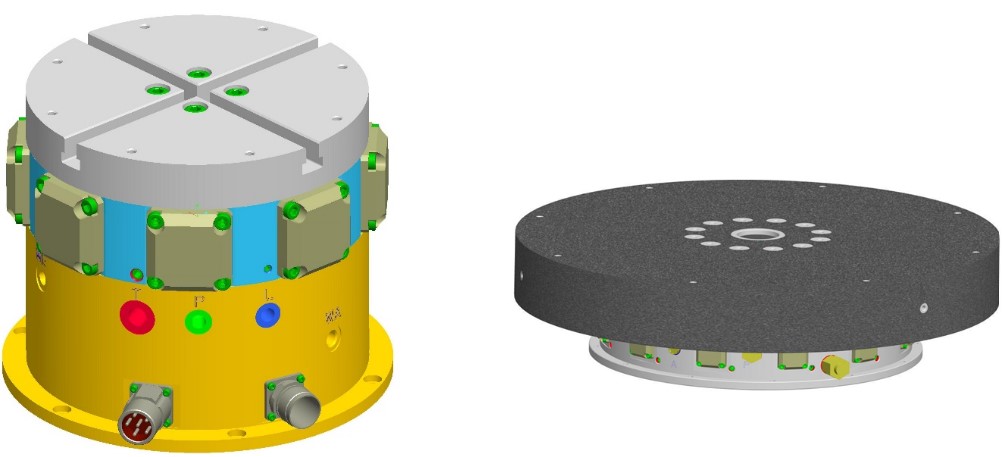

Fukudaco Hydrostatic Rotary Table / B-Axis Table

Manufacturer: Fukudaco

Overview

Hyprostatik, leveraging its proprietary hydrostatic technology, designs and manufactures linear guides, lead screws, rotary tables, and spindles as complete units. By using a specialized throttling valve (PM controller) in the hydrostatic system, they achieve characteristics that are unattainable elsewhere.

Applications

- Rotary Table

- B-Axis Rotation

Features

- High rotational accuracy

- Improved surface roughness

- High rigidity

- Equipped with a dedicated hydraulic unit

- Customizable

Advantages of Hydrostatic Rotary Tables over Spindles with Rolling Bearings

- No Wear: Hydrostatic bearings do not wear, ensuring consistent performance over long periods of use.

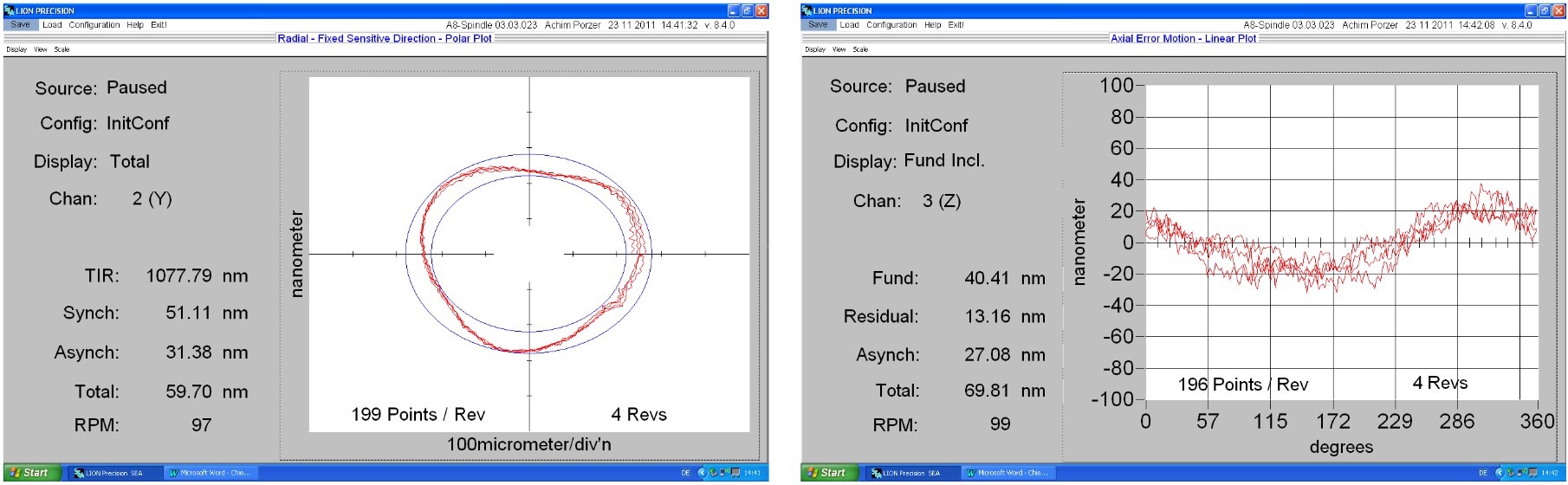

- High Runout and Rotational Accuracy: Ensures superior precision in both runout and rotation.

- High Static and Dynamic Rigidity: Offers excellent radial and axial rigidity.

- High Damping: Superior damping characteristics reduce vibrations.

- Low Friction: Achieved through a proprietary throttling valve and optimized design via computer algorithms.

- Minimized Thermal Displacement: Cooling of the oil and thermal insulation between the motor and bearings minimizes thermal displacement.

- Optimal Balance Accuracy: Ensures precise balance for high-performance applications.

PM Controller

The PM Controller is a specialized throttling valve developed exclusively by Hyprostatik for use in hydrostatic bearings.

Throttling valves for hydrostatic bearings often use various methods, with the capillary tube method being the most commonly employed. However, using the PM Controller instead of the capillary tube method achieves the following characteristics.

Advantages of Hyprostatik Hydrostatic Rotary Tables with PM Controller

- Superior Runout Accuracy ➣ Ensures exceptional workpiece cylindricity and flatness.

- No Wear ➣ Infinite lifespan and near-permanent maintenance of machine quality.

- High Damping and No Vibration ➣ Enhances surface roughness of the workpiece.

- Zero Friction and Stick-Slip at Low Speeds ➣ Positioning relies solely on the encoder system.

Specification example:

| Size designation | Ø200 | Ø300 | Ø440 | Ø600 | Ø800 | Ø990 |

|---|---|---|---|---|---|---|

| Table diameter [Ømm] | 200-300 | 300-450 | 440-580 | 600-750 | 800-1300 | 990-2000 |

| Axial load capacity at 4.0MPa ↓ (1) [N] | 4,000 | 15,000 | 40,000 | 80,000 | 200,000 | 400,000 |

| Radial load capacity at 4.0MPa (1) [N] | 1,000 | 2,000 | 5,000 | 8,000 | 20,000 | 30,000 |

| Tilting torque at 4.0MPa [Nm] | 150 | 250 | 2,000 | 4,000 | 8,000 | 12,000 |

| Axial gap stiffness [N/µm] | 4,000 | 6,000 | 8,000 | 12,000 | 18,000 | 24,000 |

| Radial gap stiffness [N/µm] | 600 | 1,500 | 3,000 | 4,000 | 5,000 | 6,000 |

| Tilt Gap Stiffness [kNm/mrad] | 3 | 20 | 130 | 270 | 540 | 900 |

| Rotational speed of oil viscosity VG68 (3) [min -1 ] | 250 | 120 | 100 | 70 | 40 | 20 |

| Flow rate of oil viscosity VG68 (2) [l/min] | 0.5 | 0.8 | 2.0 | 2.3 | 1.8 | 2.8 |

| Oil viscosity VG32 rotation speed (3) [min -1 ] | 500 | 300 | 200 | 130 | 90 | 50 |

| Flow rate of oil viscosity VG32 (2) [l/min] | 0.8 | 1.9 | 3.1 | 3.8 | 4.0 | 6.5 |

| Oil viscosity VG15 rotation speed (3) [min -1 ] | 1000 | 600 | 400 | 300 | 200 | 100 |

| Flow rate of oil viscosity VG15 (2) [l/min] | 1.8 | 3.8 | 6.7 | 8.3 | 7.4 | 13 |

| Runout accuracy during rotation (4) (radial/axial) [µm] | 0.15 | 0.15 | 0.20 | 0.25 | 0.30 | 0.30 |

(1) Load capacity can be increased by increasing pressure, and speed can be increased by increasing flow rate and decreasing viscosity.

(2) Flow rate is when oil temperature is 30°C.

(3) Maximum speed is when oil heats up to 13°K. Speed can be increased by increasing the flow rate.

(4) Under light load and no table deformation.

(5) Values can be adjusted depending on the application.

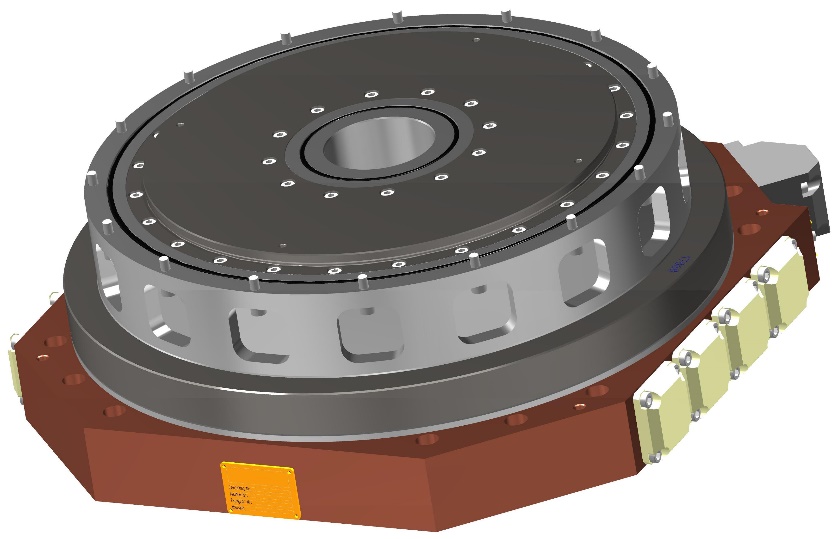

B-axis rotary table (swivel unit)

Features

- The entire swivel axis is supported by hydrostatic bearings and seals

- Equipped with a torque motor

- Includes a high-precision angular measurement encoder

- High-precision axial clamping when stopped

- Compatible with both vertical and horizontal axes

Production Examples

| z | ||

|---|---|---|

| Axial load capacity at 3.2MPa [N] | 13,000 | 20,000 |

| Tilting torque at 3.2MPa [Nm] | 1,200 | 2,200 |

| Axial load capacity at 5.0MPa [N] | 20,000 | 30,000 |

| Tilting torque at 5.0MPa [Nm] | 2,000 | 3,000 |

| Radial load capacity at 3.2MPa [N] | 1,500 | 3,000 |

| Radial load capacity at 5.0MPa [N] | 3,000 | 5,000 |

| Maximum rotation speed [°/sec] | 360 | 360 |

| Oil Viscosity | VG68, VG46, VG32 | VG68, VG46, VG32 |

| Maximum oil flow rate for VG46 @ 35°C at 3.2MPa [L/min] | 1.5 | 2.3 |

| Maximum oil flow rate for VG46 @ 35°C at 5.0MPa [L/min] | 2.2 | 3.0 |

| Maximum torque of torque motor [Nm] | 350 | 647 |

| Maximum torque motor current [A] | 31 | 31 |

| Absolute Encoder | Heidenhain RCN5580 | Heidenhain RCN8580 |

Related Products

-

Kanetec KMDS Drip-Proof Demagnetizer

-

IMADA DD2 series High Accuracy and High Capacity Load Cell

-

YOSHITAKE GP-1200S Pressure Reducing Valve – Steam

-

Seiwa WLGPA09041-CA Ceiling type Lighting Equipment And Control Equipment

-

Nippon Chemical Screw KJPA/W(d-D-t) KYOUJIN/Washer

-

Daiichi Keiki SK Series Pressure Gauge with Photoelectric Switch