Fukudaco, Japan

Fukudaco Hydrostatic Spindle

Manufacturer: Fukudaco

Overview

We support high-precision machining with our uniquely developed PM controller and specialized bearings.

Applications

- Grinding machine wheel spindles and worked spindles

- Lathe spindles

- Machining center tool spindles and more

Features

- Minimal wear

- High rigidity

- High damping capacity

- High precision

- Reduced friction and pump loss (approximately one-third that of capillary tubes)

- Capable of handling high loads even at high speeds (without loss of rigidity)

Custom-Designed Hydrostatic Spindles

We design and manufacture hydrostatic spindles according to your specifications. Below are examples of past projects.

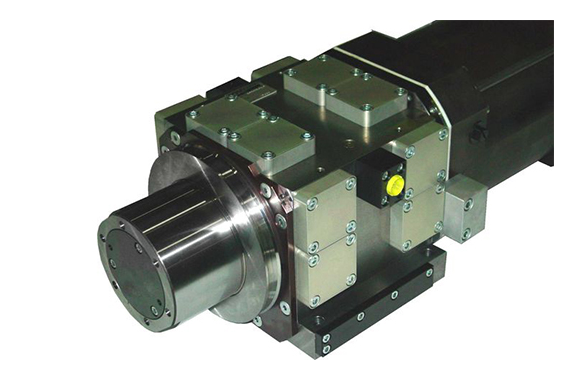

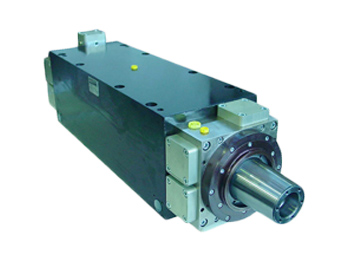

Built-in motor-driven grinding spindle

- Revolution speed: 7,600 min -1

- Pump pressure: 6.3 MPa

- Oil viscosity: ISO VG2

- Load capacity: 2,000 N

- Rigidity: 320 N/µm (with grinding wheel)

- Motor power: 50 kW

- The auto balancer can be installed

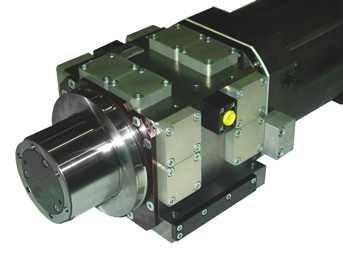

Built-in motor-driven work head spindle

- Revolution speed: 6,000 min -1

- Pump pressure: 5.0 MPa

- Oil viscosity: ISO VG2

- Load capacity: 500 N

- Rigidity: 80 N/µm (at workpiece)

- Motor power: 6.3 kW

- Rotational accuracy: < 0.15 µm

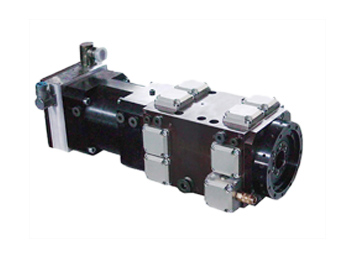

Built-in motor-driven lathe spindle

- Tip shape: DIN 55021 A8

- Revolution speed: 6,000 min -1

- Pump pressure: 6.3 MPa

- Oil viscosity: ISO VG2

- Load capacity: 10,000 N

- Stiffness: >1,000 N/µm

- Rotational accuracy: < 0.3 µm

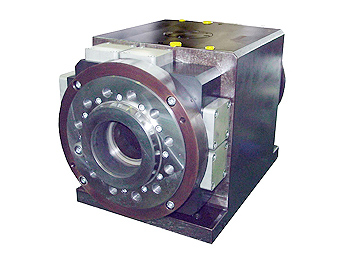

Built-in motor-driven lathe spindle

- Tip shape: DIN 55021 A5

- Revolution speed: 7,000 min -1

- Pump pressure: 8.0 MPa

- Oil viscosity: ISO VG2

- Load capacity: 6,300 N

- Stiffness: >1,000 N/µm

- Motor power: 20 kW

Built-in motor-driven milling spindle

- Tip shape: HSK-E40

- Revolution speed: 42,000 min -1

- Pump pressure: 8.0 MPa

- Fluid: Emulsion or water

- Load capacity: 500 N

- Stiffness: 160 N/µm

- Motor power: 15 kW

Belt Drive Grinding Spindle

- Revolution speed: 3,000 min -1

- Pump pressure: 5.0 MPa

- Oil viscosity: ISO VG4

- Load capacity: 2,000/4,000 N

- Stiffness: > 400 N/µm (at the grinding wheel)

- The auto balancer can be installed

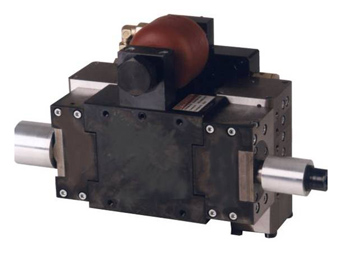

Belt-Driven Cam Grinding Spindle

- Revolution speed: 25,000/30,000 min -1

- Pump pressure: 6.3 MPa

- Oil viscosity: ISO VG2

- Load capacity: 750/500 N

- Stiffness: > 120/60 N/µm (at grinding wheel)

- Shaft to body edge dimension: 24/16 mm

- Recommended grinding wheel diameter: φ70/φ50 mm (CBN)

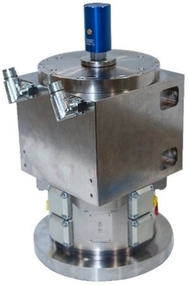

SiC wafer grinder spindles, rotary tables

- Revolution speed: 4,000 min -1

- Pump pressure: 5.0 MPa

- Load capacity (radial/axial): 1,000 N/±1,000 N

- Bearing stiffness (radial/axial): 440 N/µm/1,000 N/µm

- Runout accuracy (radial/axial): 0.03µm/0.02µm

- Uses special liquid instead of oil

- Higher rigidity than air spindles used in silicon grinders

Rotary table

- Table diameter: φ250mm

- Revolution speed: 600 min -1

- Pump pressure: 5.0 MPa

- Maximum weight of workpiece + chuck: 100 kg

- Radial bearing load capacity: 1,000 N

- Tilt torque: 100 Nm

- Position accuracy: Less than 0.20µm (encoder control)