Honda Kiko, Japan

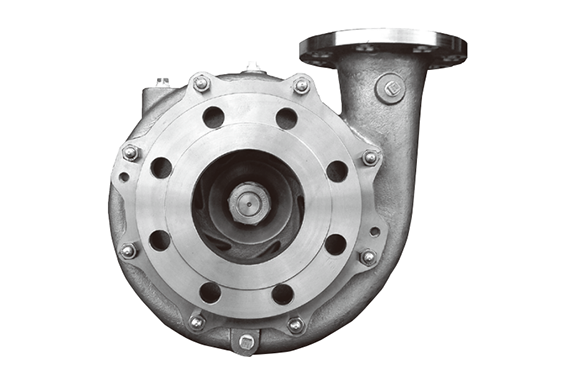

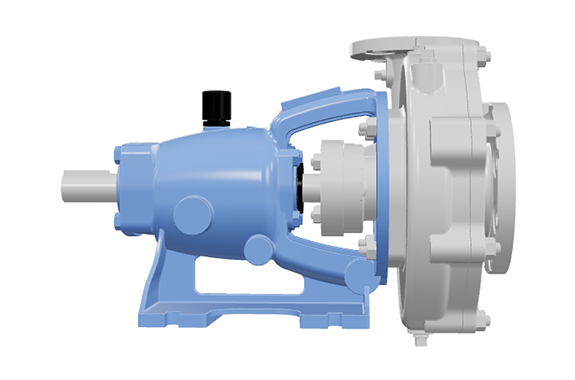

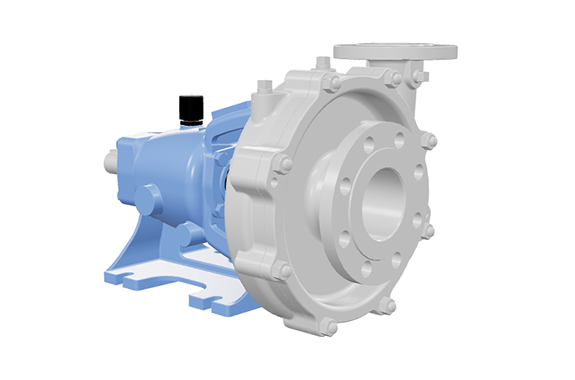

Honda Kiko HCS/HC Stainless Pumps

Product Made in Japan

Manufacturer : Honda Kiko

Model : HCS/HC

Features

- Small sized rigid type, with casting, materials and manufacturing all being strictly controlled. This pump has excellent reliability and durability.

- Standardization allows the parts to be fully interchanged.

- This pump has high efficiency over a wide flow rate and excellent suction performance.

- This pump, through many years of performance and experience, has come to be used in a wide range of applications.

Applications

- Water treating industries

Water treatment of various waste water, Sewage and Purification. - Chemical industries

Oil, Soda, Sulfuric acid and Chemical fertilizer. - Pollution control industries

Waste water treatment at diversified industries. - Dye and bleaching industries

Dye work process, Dye synthetic factories and Bleaching liquid treating process. - Oil and fat industries

Oil refining, Soap and Paint producing factories and Fuel oil transfer. - Textile industries

Spinning and Chemical fiber factories - Medicine and cosmetics industries

Medicines, Agricultural chemicals, Cosmetic producers and Hospitals - Food and beverage industries

Brewage vinegar and Japanese sake producing factories, Saltfield, Fruit juice factories, Beer and Milk factories. - Metal industries

Plate, Steel plate, Wire and Coating industries. - Agricultural and fishery

Sprinkling of agricultural chemicals, Fish farming and Sea water handling etc.

- Water treating industries

Design data

| Materials | 1. Stainless Steel SCS13A / SCS14A/SCS16 2. Cast Iron FC200 Ductile Iron FCD450-10 In this case, pump type changes to HC 3. Other specific materials pump may also be produced SCS23‧Nickel alloy‧Hastelloy‧Duplex Stainless Steel‧Titanium ‧Worthite |

| Max.pressure | 1.Stainless Steel. 1MPa 2.Cast Iron. 0.7MPa |

| Temperature | *In case of Cast & Ductile Iron, -5°C~120°C |

| Shaft seal | 1. Gland packing. Self and external flushing type. 2. Mechanical seal. a. Single mechanical seal *Unbalance type or balance type available. *Inside type or outside type available. b. Double mechanical seal. c. Single mechanical seal+Oil seal type. d. In addition, a special mechanical seal may be installed on request. *When pumping temperature exceeds 80°C, cooler shall be provided. 3. The shaft seal dimensions are structured to serve as gland packing and a mechanical seal. |

| Bearing | Ball bearing (Oil bath system) *Water jacketed bearing housing is available when pumping temperature exceeds 120°C |

| Other features | *Steam jackets are available for both sides of casing to prevent pumping liquid from solidfying *It is possible to change the direction in which the exhaust in pipe points. *The structure of the impeller. a. For pump selection numbers 219~ 1526 a. semi-open impeller is installed as a standard feature. b. For pump selection numbers 1534, 1540, 2026 and 2034, a closed impeller is installed as a standard feature. However, a semi-open impeller may also be installed on request. |

Accessories

- Base Plate

- Coupling

- Guard

- Anchor bolts/nuts

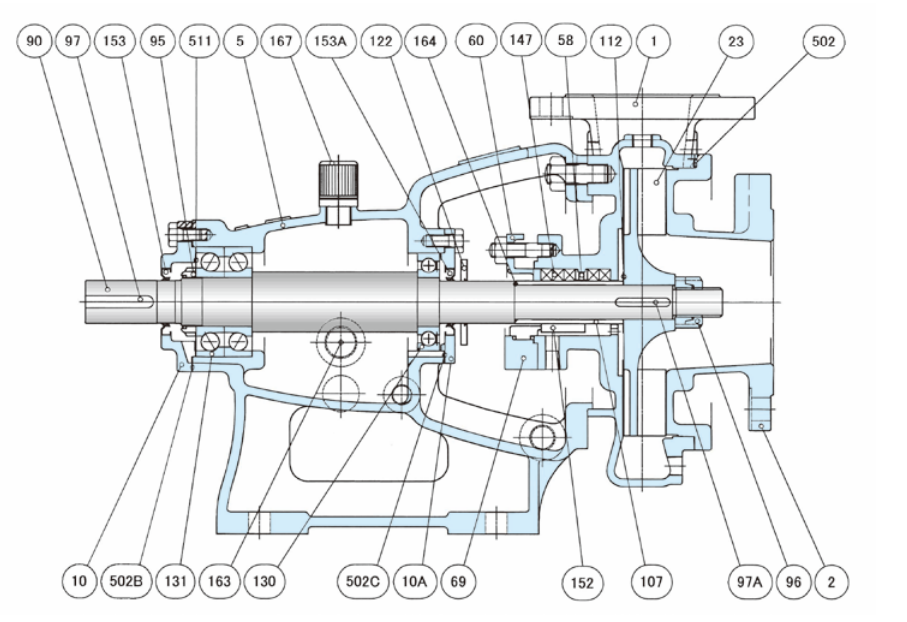

Design Concept

Materials List

| Item | Part Name | Stainless Steel | Cast Iron | |||

|---|---|---|---|---|---|---|

| 1 | Casing | SCS13A | SCS14A | Stainless steel | FC200 | Cast Iron |

| 2 | Suction cover | SCS13A | SCS14A | Stainless steel | FC200 | Cast Iron |

| 5 | Bracket | FC200 | FC200 | Cast Iron | FC200 | Cast Iron |

| 10 | Bearing cover | FC200 | FC200 | Cast Iron | FC200 | Cast Iron |

| 10A | Bearing cover | FC200 | FC200 | Cast Iron | FC200 | Cast Iron |

| 23 | Impeller | SCS13A | SCS14A | Stainless steel | FC200 | Cast Iron |

| 58 | Lantern ring | PTFE | PTFE | PTFE | PTFE | PTFE |

| 60 | Gland cover | SCS13A | SCS14A | Stainless steel | FC200 | Cast Iron |

| 69 | Seal cover | SUS304 | SUS316 | Stainless steel | SUS304 | Stainless Steel |

| 90 | Shaft | SUS304 | SCS316 | Stainless steel | S45C | Steel |

| 95 | Bearing nuts | SUM24L | SUM24L | Steel | SUM24L | Steel |

| 96 | Impeller nuts | SUS304 | SUS316 | Stainless steel | SUS304 | Stainless Steel |

| 97 | Key (Coupling side) | S45C | S45C | Steel | S45C | Steel |

| 97A | Key (Impeller side) | SUS304 | SUS316 | Stainless steel | SUS304 | Stainless Steel |

| 107 | Shaft sleeve | SUS304 | SUS316 | Stainless steel | SUS304 | Stainless Steel |

| 112 | Adjusting ring | SUS316 | SUS316 | Stainless steel | SUS316 | Stainless Steel |

| 122 | Deflector | CR | CR | CR | CR | CR |

| 130 | Bearing | SUJ | SUJ | Steel | SUJ | Steel |

| 131 | Bearing | SUJ | SUJ | Steel | SUJ | Steel |

| 147 | Gland packing | Wide choice of materials | ||||

| 152 | Mechanical seal | |||||

| 153 | Oil seal | NBR | NBR | Rubber | NBR | Rubber |

| 153A | Oil seal | NBR | NBR | Rubber | NBR | Rubber |

| 163 | Oil Gauge | Glass | Glass | Glass | Glass | Glass |

| 164 | Oring (Sleeve) | Wide choice of materials | ||||

| 167 | Oil Cap | Acryl | Acryl | Acryl | Acryl | Acryl |

| 502 | Gasket (Casing) | Wide choice of materials | ||||

| 502B | Gasket (Bearing cover) | Oil Sheet | Oil Sheet | Oil Sheet | Oil Sheet | Oil Sheet |

| 502C | Gasket (Bearing cover) | Oil Sheet | Oil Sheet | Oil Sheet | Oil Sheet | Oil Sheet |

| 511 | Thrust ring | BC | BC | BC | ||

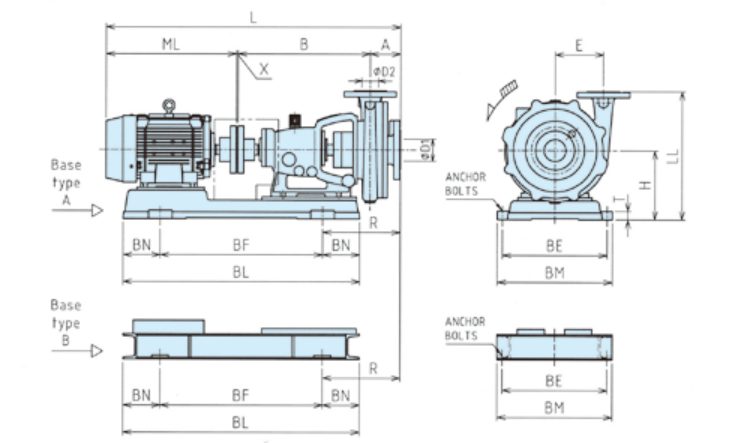

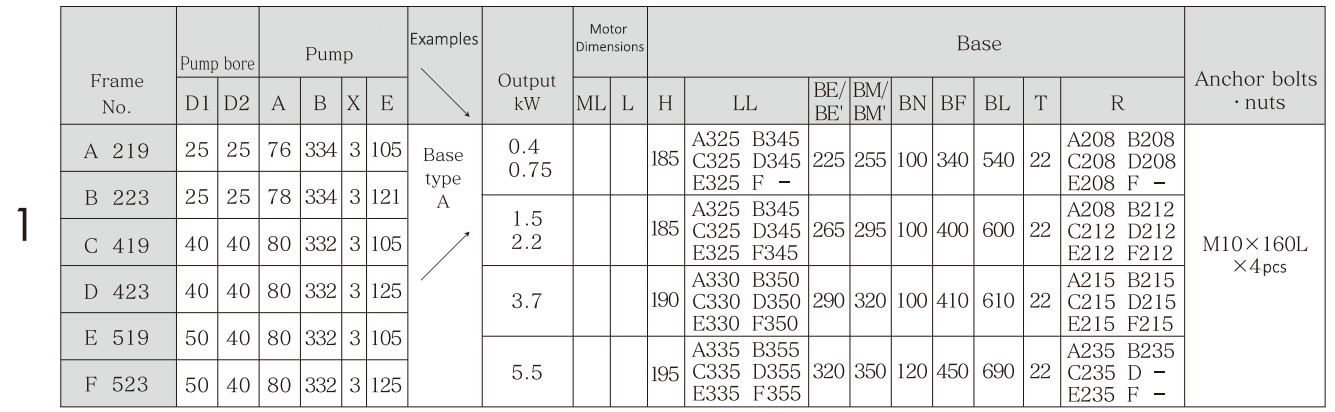

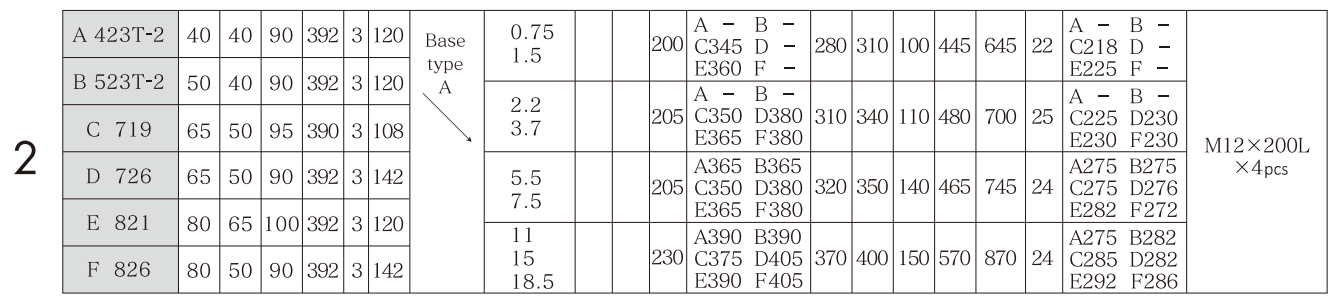

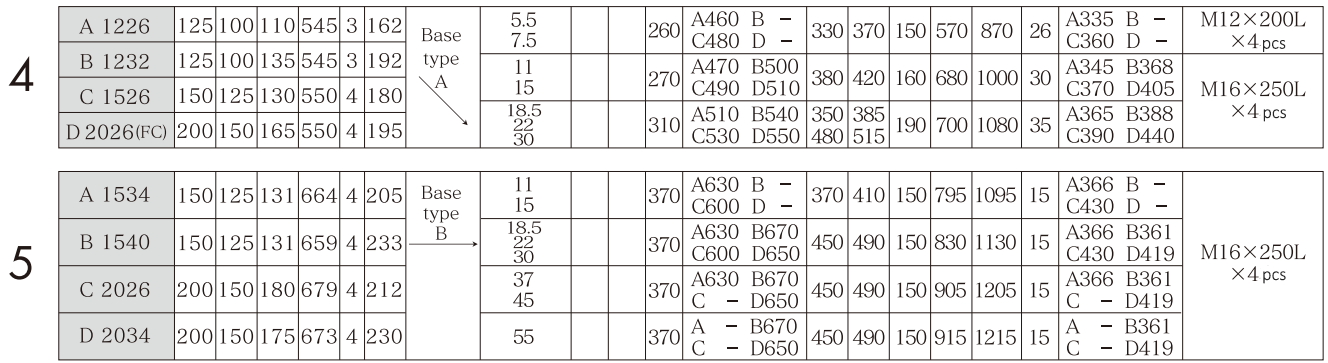

Dimensional Drawing

A guide to above dimensional information

- Pump selection number and output shall be combined with arrow.

- Dimensions are subject to change.

- 1=52 2=50 3=45 4=40 5=35

In case of Double mechanical seal, the above dimensions shall be added to B and R total.

Related Products

-

Vessel N0.350 Wooden Handle Tang-Thru Screwdriver (Long Shank Type)

-

SAKUSAKU GYG72050 Square End Mill 2-Flute

-

Watanabe WLM-PC1 Power Pulse Measurement Unit

-

Hammer Caster 515SA Handle For Scaffold Caster

-

Eagle Jack (Konno Corporation) RB-10C Roller Bar

-

Nakatani Kikai NG65L‐DRG Disc Grinder (Straight)