Japan, WINOA IKK

WINOA IKK H Urea Resin Blasting Material

Made in: Japan

Manufacturer: WINOA IKK JAPAN CO., LTD

Model: H

Features

■Type H is thermosetting formaldehyde resin media.

■It is recommended for use in the aviation industry due to its excellent abrasive power.

■ Substrate thickness of at least 0.040 inch (1 mm) is covered, residual stress is unaffected. In the semiconductor industry, it is used to remove burrs and resin extrusions on epoxy packages, especially when type XH (melamine) is too abrasive.

■Type H complies with the MIL standard specifications, MIL-P-85891, Type II.

■It is fully polymerized and does not contain free formaldehyde.

■Anti-static processing is done.

Specifications

Physicochemical properties

| material | urea resin | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| chemical property | inert | ||||||||||||||||||||||||

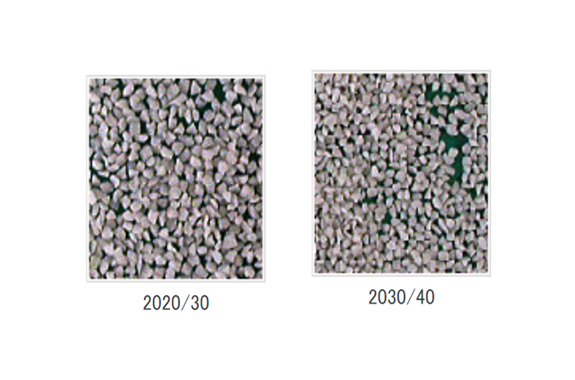

| exterior | granular | ||||||||||||||||||||||||

| colour | white or grayish white | ||||||||||||||||||||||||

| hardness | Barcol 54-62 Mohs 3.5 | ||||||||||||||||||||||||

| tensile strength | 5,000-1,5000 psi | ||||||||||||||||||||||||

| Elongation | 0.6-1.0% | ||||||||||||||||||||||||

| compressive strength | 25,000-45,000 psi | ||||||||||||||||||||||||

| Izod impact test | 0.2-0.4 ftlb/in | ||||||||||||||||||||||||

| explosive concentration _ | 0.085 oz/cuft | ||||||||||||||||||||||||

| ignition temperature | 530℃ | ||||||||||||||||||||||||

| specific gravity | 1.45-1.50 | ||||||||||||||||||||||||

| Basic granularity |

| ||||||||||||||||||||||||

| Packing | 20kg carton box | ||||||||||||||||||||||||

| place of origin | Malaysia |