Concrete Work, CONSTRUCTION, Insert, Japan, Japan Life

Japan Life P Insert (JL Insert Series)

Product Made in Japan

Manufacturer: Japan Life

Selection of JL Inserts

At the selection of JL Inserts,please consider below factors and apply the minimum values.

① The bolt (Subject to SS400 / SUS304)

② The Insert

③ Concrete’s tensile strength

Please apply minimum values of ①②③ and fully consider the safety factors.

Concrete’s tensile strength in the chart is base on HANDBOOK of VARIOUS SYNTHE TIC CONSTRUCTIONDESIGN of Archtecural Institute of Japan.

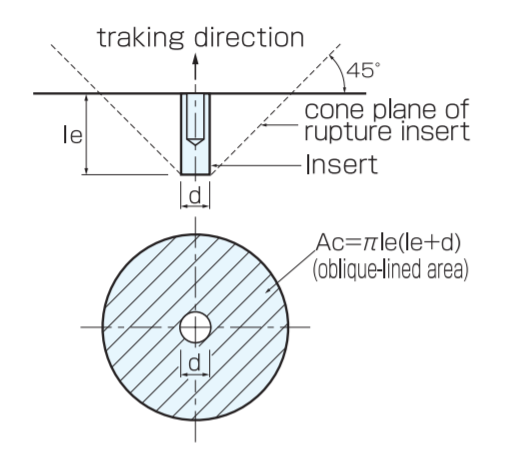

Tensile strength = φ1× ×π×le(le+d)×0.313209(FC = N/mm2)

φ1= 0.6(short-term load)

Unit: kN

| Product name (Shape) | Specification (mm) | ①Bolt | ②Insert | ③Concrete’s tensile strength | Remark | |||||

| thread | length | tracting (kN) | Shearing (kN) | trac ting (kN) | Shea ring (kN) | Fc=12 (N) | Fc= 30 (N) | Fc =60 (N) | ||

|

| M6 | 30 | 4.72 | 2.71 | 26.46 | 15.2 | 2.65 | 4.19 | 5.92 | Bolt: SS400 |

| M8 | 30 | 8.6 | 4.94 | 22.58 | 12.97 | 2.65 | 4.19 | 5.92 | ||

| M10 | 20 | 13.63 | 7.83 | 17.55 | 10.08 | 1.32 | 2.08 | 2.95 | ||

| 30 | 2.65 | 4.19 | 5.92 | |||||||

| M12 | 40 | 19.81 | 11.38 | 17.55 | 17.48 | 4.41 | 6.98 | 9.87 | ||

| 80 | 15.54 | 24.57 | 34.75 | |||||||

| M16 | 35 | 36.89 | 21.19 | 50.80 | 29.18 | 3.89 | 6.16 | 8.71 | ||

| 50 | 7.21 | 11.4 | 16.12 | |||||||

| 75 | 14.77 | 23.36 | 33.04 | |||||||

| 100 | 24.9 | 39.37 | 55.68 | |||||||

| M20 | 100 | 57.57 | 33.07 | 108.52 | 62.34 | 25.95 | 41.03 | 58.03 | ||

PT Insert PT Insert | M6 | 45 | 4.72 | 2.71 | 26.46 | 15.2 | 5.41 | 8.55 | 12.1 | |

| M8 | 45 | 8.6 | 4.94 | 22.58 | 12.97 | 5.41 | 8.55 | 12.1 | ||

| M10 | 45 | 13.63 | 7.83 | 17.55 | 10.08 | 5.41 | 8.55 | 12.1 | ||

| M12 | 64 | 19.81 | 11.38 | 30.43 | 17.48 | 10.3 | 16.29 | 23.04 | ||

| M16 | 75 | 36.89 | 21.19 | 50.80 | 29.18 | 14.77 | 23.36 | 33.04 | ||

| 95 | 22.67 | 35.84 | 50.69 | |||||||

PK Insert PK Insert | W3/8 | 35 | 11.53 | 6.62 | 19.64 | 11.28 | 3.46 | 5.48 | 7.75 | |

| W1/2 | 55 | 20.53 | 11.79 | 29.7 | 17.06 | 7.82 | 12.36 | 17.49 | ||

| W5/8 | 80 | 33.81 | 19.42 | 53.88 | 30.95 | 16.59 | 26.24 | 37.11 | ||

| M12 | 55 | 13.81 | 11.38 | 30.43 | 17.48 | 7.82 | 12.36 | 17.49 | ||

| M16 | 80 | 36.89 | 21.19 | 50.8 | 29.18 | 16.59 | 26.24 | 37.11 | ||

PQ Insert PQ Insert | M10 | 40 | 13.63 | 7.83 | 17.55 | 10.08 | 4.38 | 6.93 | 9.81 | |

| M12 | 40 | 19.81 | 11.38 | 30.43 | 17.48 | 4.41 | 6.98 | 9.87 | ||

| 50 | 6.58 | 10.41 | 14.72 | |||||||

| M16 | 45 | 36.89 | 21.19 | 50.80 | 29.18 | 6 | 9.49 | 13.42 | ||

| 60 | 9.93 | 15.7 | 22.2 | |||||||

FCI Insert FCI Insert | M10 | 43 | 11.89 | 6.84 | – | – | 5.28 | 8.35 | 11.81 | Bolt: SUS304 |

| M12 | 60 | 17.28 | 9.94 | – | – | 9.58 | 15.15 | 21.43 | ||

| M16 | 65 | 32.18 | 18.52 | – | – | 12.53 | 19.81 | 28.02 | ||

| 75 | 16 | 25.31 | 35.79 | |||||||

| 85 | 19.89 | 31.45 | 44.48 | |||||||

| M20 | 100 | 50.22 | 28.91 | – | – | 27.57 | 43.59 | 61.65 | ||

| M22 | 110 | 62.11 | 35.75 | – | – | 32.73 | 51.75 | 73.19 | ||

| M24 | 120 | 72.36 | 41.65 | – | – | 39.38 | 62.26 | 88.05 | ||

SUS-IP Insert SUS-IP Insert | M6 | 30 | 4.12 | 2.37 | 19.7 | 11.37 | 2.57 | 4.07 | 5.75 | |

| M8 | 30 | 7.5 | 4.31 | 16.81 | 9.7 | 2.57 | 4.07 | 5.75 | ||

| M10 | 30 | 11.89 | 6.84 | 13.07 | 7.54 | 2.57 | 4.07 | 5.75 | ||

| 50 | 6.41 | 10.14 | 14.35 | |||||||

| M12 | 40 | 17.28 | 9.94 | 22.66 | 13.07 | 4.31 | 6.83 | 9.65 | ||

| 50 | 6.46 | 10.22 | 14.46 | |||||||

| 80 | 15.36 | 24.29 | 34.75 | |||||||

| M16 | 50 | 32.18 | 18.52 | 39.04 | 22.53 | 6.59 | 10.42 | 14.74 | ||

| 75 | 13.9 | 21.98 | 31.09 | |||||||

| 100 | 23.77 | 37.59 | 53.16 | |||||||

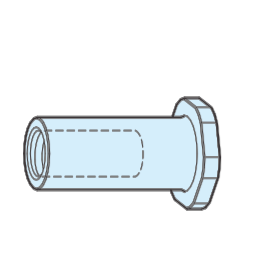

Product Features

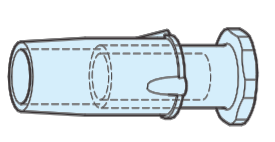

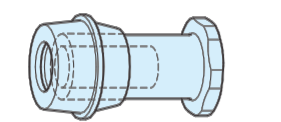

- The product has strong characteristic at the form of bottom part of insert which provide strong fix level to concrete

- Line up includes metric screw thread and Whitworth screw thread.

- Material: SWRCH

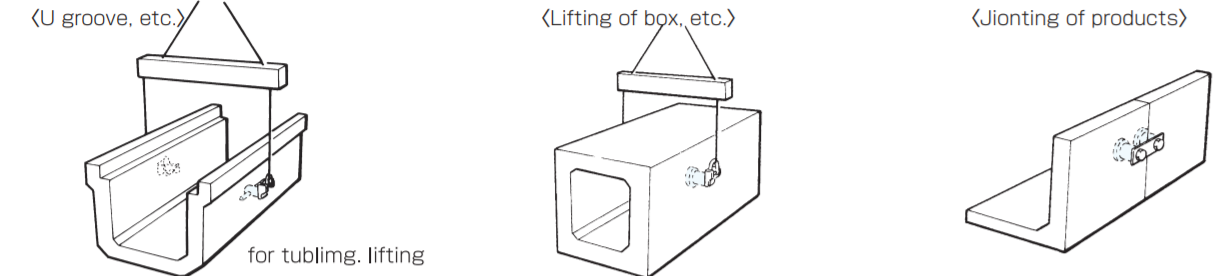

Application

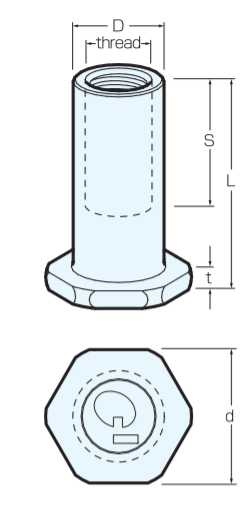

Specification

Unit: mm

| Thread | diameter | length(L) | achor part | Jig(Cap) | |||||||||||||

| L | 20 | 30 | 35 | 40 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 100 | d | t | |||

| M6 | 13 | Stock | ◎ | ◎ | 21 | 3 | – | ||||||||||

| Length(S) | 10 | 12 | |||||||||||||||

| Qty | 1000 | 700 | |||||||||||||||

| M8 | 13 | Stock | ◎ | ◎ | ◎ | 21 | 3 | – | |||||||||

| Length(S) | 12 | 15 | 20 | ||||||||||||||

| Qty | 1000 | 700 | 400 | ||||||||||||||

| M10 | 13 | Stock | ◎ | ◎ | ◎ | 21 | 3 | A | |||||||||

| Length(S) | 15 | 20 | |||||||||||||||

| Qty | 700 | 400 | |||||||||||||||

| M12 | 16.5 | Stock | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | 24 | 4 | C | ||||||

| Length(S) | 20 | 25 | 30 | 30 | 30 | 30 | |||||||||||

| Qty | 400 | 300 | 300 | 200 | 200 | 150 | |||||||||||

| M16 | 21.8 | Stock | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | 32 | 4.5 | L | |||||

| Length(S) | 25 | 25 | 30 | 30 | 30 | 35 | 40 | ||||||||||

| Qty | 200 | 150 | 150 | 150 | 100 | 100 | 70 | ||||||||||

| M20 | 30 | Stock | ◎ | ◎ | ◎ | 41 | 6 | J | |||||||||

| Length(S) | 30 | 35 | 40 | ||||||||||||||

| Qty | 70 | 60 | 40 | ||||||||||||||

| W5/16 | 13 | Stock | ◎ | ◎ | 21 | 3 | – | ||||||||||

| Length(S) | 12 | 15 | |||||||||||||||

| Qty | 1000 | 700 | |||||||||||||||

| W3/8 | 13 | Stock | 21 | 3 | A | ||||||||||||

| Length(S) | |||||||||||||||||

| Qty | |||||||||||||||||

| W1/2 | 16.5 | Stock | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | 24 | 4 | C | ||||||

| Length(S) | 18 | 25 | 30 | 30 | 30 | 30 | |||||||||||

| Qty | 400 | 300 | 300 | 200 | 200 | 150 | |||||||||||

| W5/8 | 21.8 | Stock | ※ | ※ | ◎ | ※ | ◎ | ※ | 32 | 4.5 | R | ||||||

| Length(S) | 25 | 25 | 30 | 30 | 35 | 40 | |||||||||||

| Qty | 200 | 150 | 150 | 150 | 100 | 70 | |||||||||||

| W3/4 | 30 | Stock | 41 | 6 | J | ||||||||||||

| Length(S) | |||||||||||||||||

| Qty | |||||||||||||||||

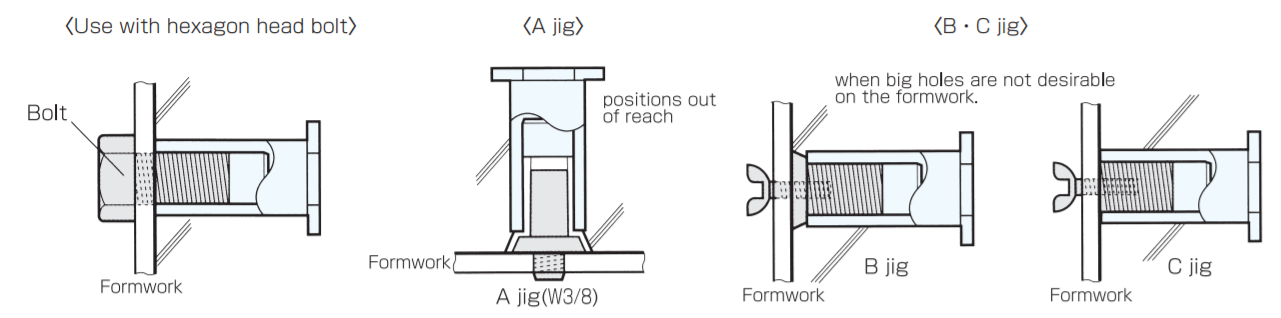

How to apply

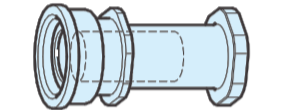

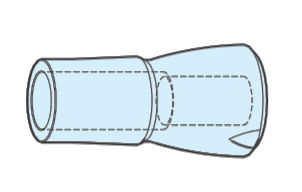

P Insert

P Insert