Japan, Kakuta

Kakuta No.200 Air Clamp

Product Made in Japan

Manufacturer: Kakuta Co., Ltd

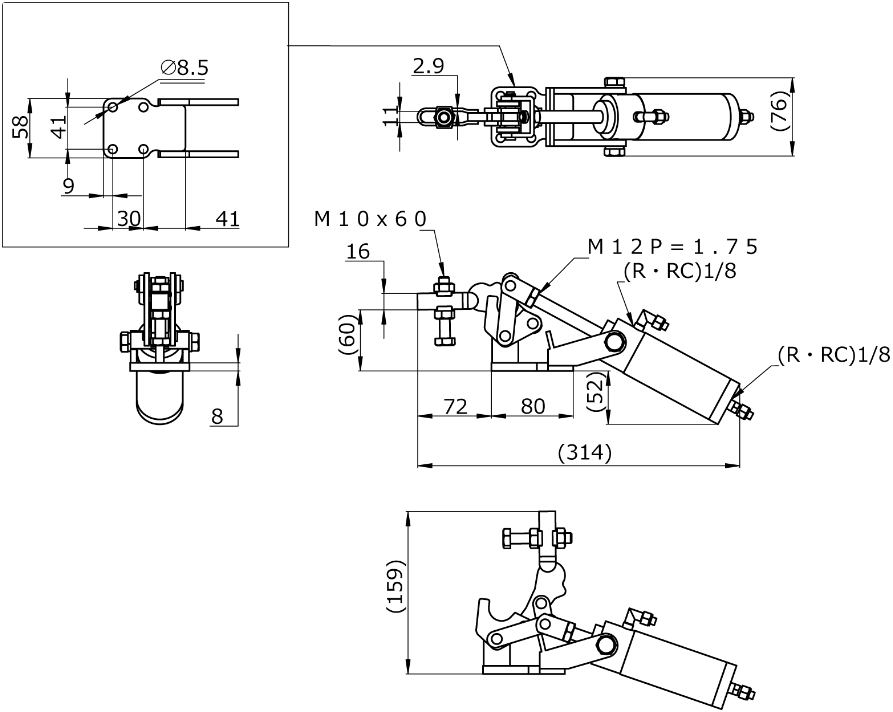

Model: No.200

No.200 (Air Clamp (Hold down clamp))

| Category | Air Clamp |

|---|---|

| Model Number | No.200 |

| Weight | 2,260g |

| Holding Capacity | 1.0kN(0.5Mpa) |

| Material | Steel(SPCC) |

| Mounting Method | Flange Base |

| Surface finish | Trivalent Chromate |

CAD data

Air clamp is optimal for automation equipments.

You can operate multiple air clamps at same time that improve your work efficiency when you use in inside of machine or holding a huge workpiece.

The holding capacity is maximum value(Air supply pressure at 1.0MPa)

Please use at 0.4 – 0.6MPa (40 – 60% of holding capacity)

To protect sputter and dust, a heat-resistant bellows can attach to air clamp.

Example Of Air Clamp Schematic

Air Clamp Instraction

- Hold down type perform maximum holding force at the nearest position of the body and it is the weakest force at the tip of the arm.

Changing Direction Of Air Fitting

- When you change the direction of the air fitting, remove the thread sealing tape first then wind new sealing tape and change the direction.

- If do not remove the sealing tape and change direction, there is a possibility of air leaking.

Use In High Temperature

- Optimal operation tempareture range is 5 to 60 deg.C.

- Do not use at colder than 5deg.C or higher than 60deg.C.

- If you will use at higher than 60deg.C, must measure a thermal insulation and shield.

- If do not measure, there is a possibility of melting O-ring inside of air cylinder and air leaking.

- We do not take a responsibility that failure due to using at low or high tempareture.

Air Clamp Instruction

Read before use

<Check before use>

- Air clamp designed to use in air. Do not use in hydrulic.

- Operation air pressure range is 0.4 – 0.6MPa.

- Be sure a safety for workers during operation.

- The holding capacity noted in catalog is maximum values at supply air pressure 0.5MPa.

- The value cannot be guaranteed as it bepends on the condition of use.

Use caution as the holding force will drop due to depending on the holding location, bolt adjustment, type of bolt uses and supply air pressure.

When selecting and using air clamps, allow enough margin for the holding capacity

<Precaution>

- Mounting Method: Mount by fixing bolts or by welding securely.

- Clean plumbing: Before connecting a tube to an air clamp, flow air at 0.3MPa min. to clean the inside of tube.

- Air supply: Use clean and dry air. Operating temperature: 5 – 60 deg. C Do not use in higher than 60 deg.C

- Operating environment: Do not use in the corrosive environment.

- Plumbing: Set up air circuit.

- Lubrication: Apply oil to the slides and friction parts on a regular basis. Recommend using NPC Permalub H1002 or equivalent.

- Operating Test: Check the operation before and after mounting and connecting tubes.

- Holding position: It does not hold or clamp on the way of actuating. Be sure to finish the actuation.

- Chip removing: When using in place where there are chips, remove chips around the unit, especially the rivets and rotating parts by using an airgun before unclampling.

- Precaution: Do not insert your hands and fingers in range of the action and wear protective gloves for safety when mounting or using.

- Inspection: Inspect regularly for any loose bolts that mounts the air cylinder. Also inspect bolts, nuts that secures the clamp shaft, clamp bolt and body.

<Instruction>

- Clamp: To supply air pressure to the end of air cylinder. The cylinder lod push the clamp arm to downward then clamp.

- Unclamp: Switch the air supply and the rod makes the clamp arm move to upward then unclamp.

- Adjust speed: Use a speed controller valve and adjust the speed.

DANGER !! Do not insert your hands/fingers in range of the action during operation.

Required At Clean Environment

- There is a possibility that oozing lubricants from air cylinder due to condition as higher than 40deg.C, keep pressing and low operation ratio.

- If you use in the place that requested cleanness, be sure the above.