Japan, Kakuta

Kakuta No.51BS Straight Line Clamp

Product Made in Japan

Manufacturer: Kakuta Co., Ltd

Model: No.51BS

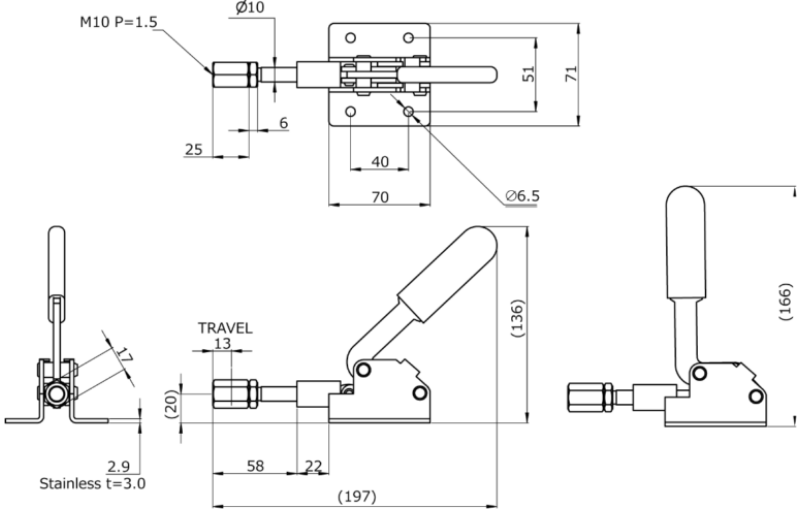

No.51BS (Straight Line)

| Category | Straight Line |

|---|---|

| Model Number | No.51BS |

| Weight | 480g |

| Holding Capacity | 1.6kN(160kgf) |

| Material | Steel(SPCC) |

| Mounting Method | Flange Base |

| Surface finish | Nickel Plating |

CAD Data

Stroke 13mm

Feature

- A toggle clamp is designed to hold a workpiece by one-action operation after initial setting.

- It is easy to introduce and low cost compare with air or hydraulic.

Application

- Optimal for repetitive work

- For inspection, welding, assembly, machining and press fit.

- You can use for woodworking and DIY.

Caution

- The holding capacity is for reference.

- Do not give the shock, vibration and internal pressure which causes a failure.

- Caution to pinch the fingers.

Toggle Clamp Instruction

Read before use

<Check before use>

- The holding capacity noted in catalogue is maximum value.

- The value cannot be guaranteed as it bepends on the condition of use.

- Use caution as the holding force will drop due to depending on the holding position, bolt adjustment and type of bolt uses.

- When selecting and using clamps, allow enough margin for the holding capacity.

<Precaution>

- Mounting Method: Mount by fixing bolts or by welding securely.

- Test: Before mount, test the action.

- Extension Handle: Using with an extension handle or arm will have a negative effect on durability.

- Holding Position: It does not hold or clamp on the way of actuating. It only can hold at holding position. (Toggle and cam mechanism at work)

- Lubrication: Apply oil to the slides and friction parts on a regular basis.

- Chip removing: When using in place where there are chips, remove chips around the main unit, especially the rivets and rotating parts by using an airgun before clamping & unclamping.

- Inspection: Inspect regularly for bolts and nuts that secures the body and clamp arm, damage and transform.

- Operating environment: Using in the corrosive or inappropriate environment causes mulfanction, damage and transform.

- Precaution: Do not insert your hands and fingers in range of the action and wear protective gloves for safety when mounting or operation. Do not use at exceed the holding capacity.

Related Products

-

NK-1200 Threaded Type Flexible Hose (Multiuse Union Type)

-

Chiyoda Seiki Type G Cutter For Cutting Thin To Thick Plates (For AC/LPG)

-

Super Tool HLC0.5H-10WH Lateral Lifting Clamp (Lock Handle Type)

-

Niigata Seiki PRT-19S Protractor No.19 Silver

-

TONE 401 Offset Handle

-

Tosei Sharyo GLF-B(Table) Hydraulic Lifter