Japan, Kakuta

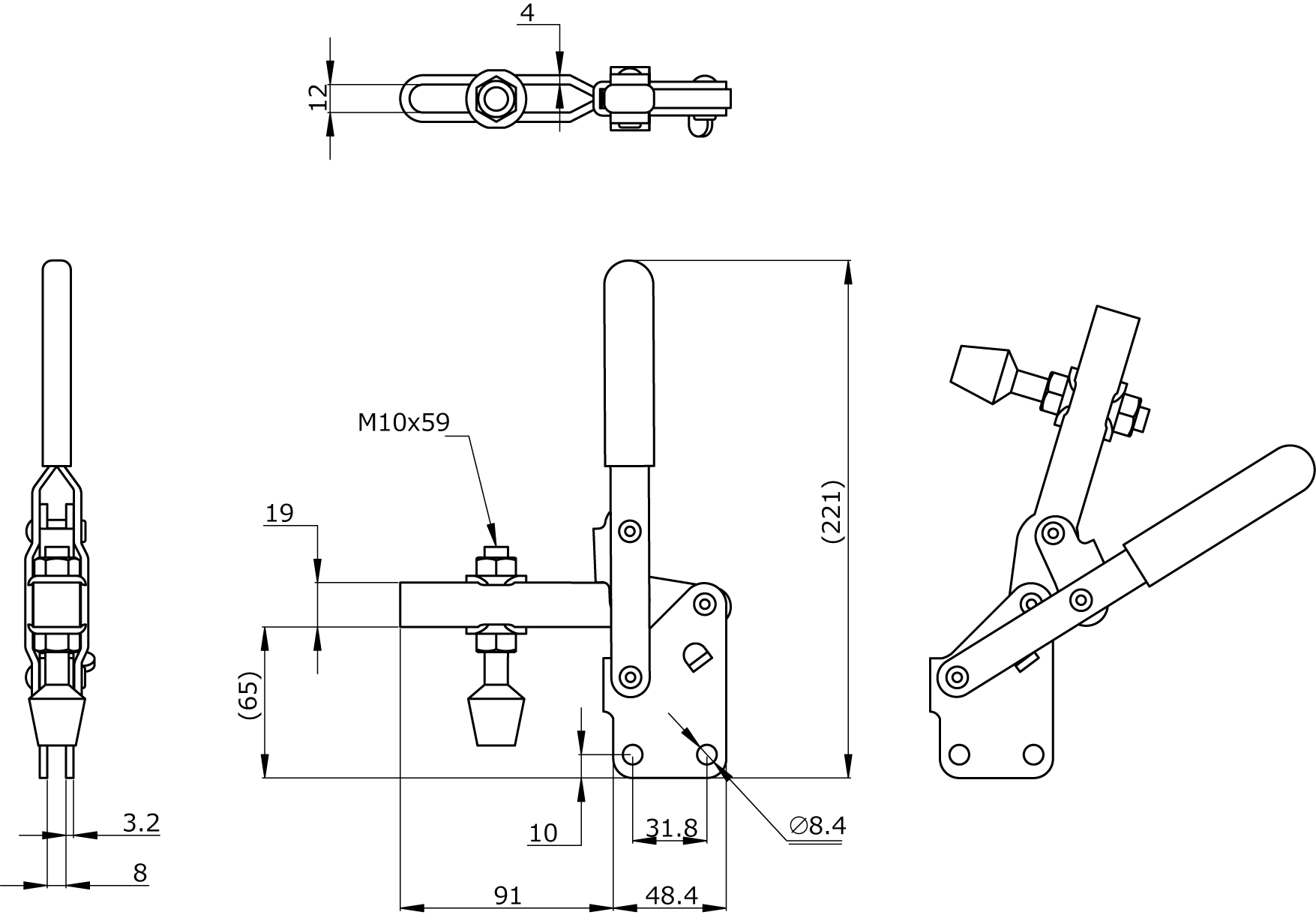

Kakuta No.HV651B Hold Down Clamp

Product Made in Japan

Manufacturer: Kakuta Co., Ltd

Model: No.HV651B

No.HV651B (Hold down clamp (Vertical Handle))

| Category | Hold down Clamp |

|---|---|

| Model Number | No.HV651B |

| Weight | 600g |

| Holding Capacity | 3.4kN(340kgf) (Maximum Value when using hexagon Bolts.) |

| Material | Steel(SPCC) |

| Mounting Method | Straight Base |

| Surface finish | Nickel Plating |

CAD data

Feature and Application

- A toggle clamp is designed to hold a workpiece by one-action operation after initial setting.

- It is easy to introduce and low cost compare with air or hydraulic.

- Optimal for repetitive work.

- For inspection, welding, assembly, machining and press fit.

- You can use for woodworking and DIY.

Caution

- The holding capacity is for reference. Max. value is by using hex bolt.

- The holding capacity will decrease toward the tip of clamp arm.

- Do not give the shock, vibration and internal pressure which causes a failure.

- Caution to pinch the fingers

Toggle Clamp Instruction

Read before use

<Check before use>

- The holding capacity noted in catalogue is maximum value.

- The value cannot be guaranteed as it bepends on the condition of use.

- Use caution as the holding force will drop due to depending on the holding position, bolt adjustment and type of bolt uses.

- When selecting and using clamps, allow enough margin for the holding capacity.

<Precaution>

- Mounting Method: Mount by fixing bolts or by welding securely.

- Test: Before mount, test the action.

- Extension Handle: Using with an extension handle or arm will have a negative effect on durability.

- Holding Position: It does not hold or clamp on the way of actuating. It only can hold at holding position. (Toggle and cam mechanism at work)

- Lubrication: Apply oil to the slides and friction parts on a regular basis.

- Chip removing: When using in place where there are chips, remove chips around the main unit, especially the rivets and rotating parts by using an airgun before clamping & unclamping.

- Inspection: Inspect regularly for bolts and nuts that secures the body and clamp arm, damage and transform.

- Operating environment: Using in the corrosive or inappropriate environment causes mulfanction, damage and transform.

- Precaution: Do not insert your hands and fingers in range of the action and wear protective gloves for safety when mounting or operation. Do not use at exceed the holding capacity.