Japan, Kanetec

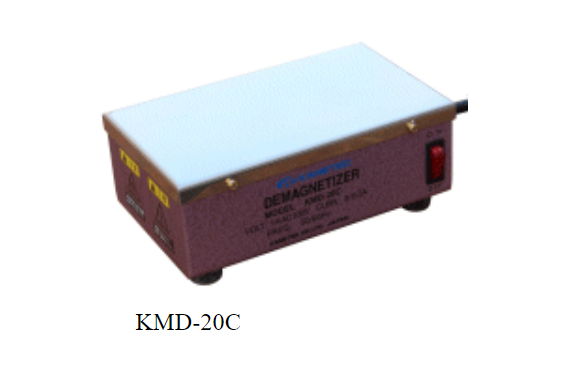

Kanetec KMD Table Type Demagnitizer

Product Made in Japan

Manufacturer: Kanetec

Model: KMD

Compact but improved demagnetizing performance!

Application

These demagnetizers produce an alternating magnetic field on the surface by use of an AC power source through which workpieces are passed to remove the magnetism remaining on their surface.

Features

- Thick workpieces can be demagnetized effectively by passing the front and rear side over the demagnetizer.

- These demagnetizers are very powerful and can demagnetize steel materials such as high speed steel, bearing steel, nickel-chrome steel, spring steel, die steel, etc. which are difficult to demagnetize by standard demagnetizers (since these steels have the property similar to magnetic steel which retains residual magnetism and is hard to remove).

- These demagnetizers have good heat radiation and can withstand continuous power application.

[mm(in)]

Model | Power Source | Power Capacity (Current) | Working Rate | Effective Demag. Width | Dimensions | Mass | ||

| B | L | H | ||||||

| KMD-2A | 3-phase 200 VAC, 50/60 Hz | 2kVA(5.8A) | 100%ED | 160(6.29) | 453(17.8) | 245(9.64) | 140(5.51) | 30kg/66 lb |

| KMD-15C | Single-phase 100 VAC, 50/60 Hz | 140VA(1.4A) | 80(3.15) | 150(5.90) | 120(4.72) | 80(3.15) | 5kg/11 lb | |

| KMD-20C | 300VA(3.0A) | 130(5.11) | 200(7.87) | 7kg/15 lb | ||||

| KMD-30C | Single-phase 200 VAC, 50/60Hz Single-phase 220 VAC, 60Hz | 0.74kVA(3.7A) | 180(7.08) | 300(11.8) | 200(7.87) | 120(4.72) | 19kg/41 lb | |

| KMD-40C | 1.04kVA(5.2A) | 280(11.0) | 400(15.7) | 29kg/63 lb | ||||

| KMD-50C | 1.28kVA(6.4A) | 380(14.9) | 500(19.6) | 37kg/81 lb | ||||

※Cable, 2 m, included. ※KMD-15C/20C come with a ground plug.

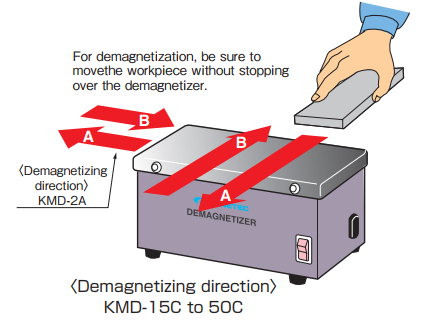

How to Demagnetize and Precautions for Use

Caution: High temperature

- Be sure to observe the working rate.

- Move a workpiece over the demagnetizing surface slowly in the direction of A-B. Note that the workpiece must be moved more than 20 cm away from the end of the demagnetizer to be demagnetized effectively. (Table type)

- When the tunnel type demagnetizer is used, pass the workpiece through the tunnel.

- The recommended time for passing the workpiece is about 5 seconds. (Recommended speed: 3 to 5 m/min)

- Some demagnetizers may be heated to very high temperature due to electromagnetic induction action. Exercise caution when handling them.

- If there is any other metal near the demagnetizer, it may also be heated. Keep such metal at least 5 cm away from the demagnetizing surface, and approx. 30cm or more away when the tunnel type demagnetizer is used. However, if such separation is not possible, use plastics or nonmagnetic materials such as SUS304 for peripheral machinery.

- The strong magnetic field produced by the demagnetizer may cause the CRT of computer and NC units to flicker. It will not adversely affect the operation of these equipment, but if it causes a recognition problem, such measures must be taken as keeping the CRT away from the demagnetizer or installing a magnetic shield on the CRT side.

- The demagnetizers have large inductance and low power factor. Take influence on the power source into consideration.

- The standard models cannot be used on 220 VAC, 50 Hz. For such application, please contact us.

- The demagnetization effect varies largely depending the conditions of workpieces. In particular, some materials are very difficult to demagnetize depending on the condition of heat treatment.

- If you send samples of workpieces, we will check the demagnetization effect for you.

How to use

Kouei is Distributor/Agent of Kanetec.

Other items of Kanetec

Request the quotation for Kanetec

Related Products

-

Kamiuchi Garbage crane Specialized Cranes

-

Hammer Caster 900-2, 900-4, 900-5 Baking Finished Steel Made Hammer Lock

-

Kurimoto CD- 80, CD- 100, CD- 160, CD- 250, CD- 300 Indirect Heating Dryer

-

TERAOKA SEISAKUSHO 760H #25 Double-coated Adhesive Kapton(R) Film Tape

-

TPS-08/TPS-09 Taper Pin Punch Set

-

Nippon Chemical Screw PEI/PBO 19.5-24-36L PEI/Ω (omega type)