Japan, Kanetec

Kanetec KVR Vacuum Chucks

Product Made in Japan

Manufacturer: Kanetec

Model: KVR

![]()

Application

Chucks to hold workpieces by utilizing atmospheric vacuum pressure. Nonmetallic and nonmagnetic materials can be held and machined. These chucks are suitable for grinding and cutting plastics and grinding aluminum, brass, stainless steel, ceramic, and glass.

Features

- You can arrange the suction holes on the chuck work face to set an effective holding area according to the shapes of workpieces by combining the adjustment of thread valves and valves.

- The suction holes have cross grooves to expand the acting area. Thus, few thread valves are used to improve work efficiency.

- We make the chuck work face from iron to allow self-grinding to recover parallelism.

- Since we make the chuck work face of iron, users can utilize magnetic devices such as workpiece stoppers.

- You can install a special suction hole layout adapter according to the workpieces and work procedures.

- One can mount these chucks on magnetic chucks.

- The absence of a heat source or moving parts inside the chucks ensures highly precise machining.

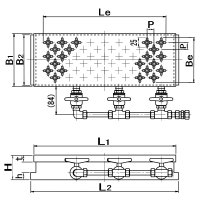

KVR-D (Thread valve type)

- An effective holding area can be set according to the shapes of workpieces by combined adjustment of thread valves and valves.

- Since suction grooves of cross shape are provided on the holding face, the number of thread valves has been reduced to enhance the work efficiency.

KVR-H (Small hole type)

- Holes of φ4 are provided on the holding face at 8-mm pitches.

| <Precautions for use> The vacuum chuck is of such construction that the inside of the chuck is exhausted by a vacuum pump to reduce the internal pressure and a workpiece is held by atmospheric pressure. Therefore, the holding power is determined by a difference between atmospheric pressure and holding area. Due to physical restrictions, a pressure difference that can be obtained by a pump is about 80 kPa (600 mmHg) in consideration of the upper limit of available exhaust efficiency. Since the same holding power as about 80 kPa (0.8 kgf/cm2) can be obtained, if the holding area of a workpiece is 100 cm2, it is held by a holding power of about 800 N (80 kgf). Note, however, that if the holding face of workpieces is rough or distorted, if small, an atmospheric pressure leak occurs to decrease the holding power significantly. For such workpieces, some leak-preventing measures must be taken. Workpieces could be deformed by heat generated during machining depending on the materials and thickness of the workpieces. Pay attention to machining methods. In particular, thin stainless steel plates deform due to machining heat and are difficult to hold. If you have questions, please contact us. |

Specification

| [mm(in)] | |||||||||||||

| Model | Nominal Size | Work Face | Hole Pitch | Mounting Face | Height | Mass | Applicable Vacuum System |

||||||

| B1 | L1 | t | Be | Le | B2 | L2 | h | H | |||||

| KVR-2D1018 | 100(3.93) ×175(6.89) |

100 (3.93) |

175 (6.89) |

20 (0.78) |

85 (3.34) |

145 (5.70) |

P=20 (Staggered layout) (0.78) |

96 (3.78) |

195 (7.67) |

20 (0.78) |

70 (2.75) |

9kg/ 19lb |

VPU-E10 VPU-E20 VPU-D20 |

| KVR-2D1325 | 125(4.92) ×250(9.84) |

125 (4.92) |

250 (9.84) |

105 (4.13) |

225 (8.85) |

121 (4.76) |

270 (10.6) |

15kg/ 33lb |

|||||

| KVR-2D1515 | 150(5.90) ×150(5.90) |

150 (5.90) |

150 (5.90) |

125 (4.92) |

125 (4.92) |

146 (5.74) |

170 (6.69) |

11kg/ 24lb |

|||||

| KVR-2D1530 | 150(5.90) ×300(11.8) |

300 (11.8) |

245 (9.64) |

320 (12.6) |

22kg/ 48lb |

||||||||

| KVR-2D1545 | 150(5.90) ×450(17.7) |

450 (17.7) |

405 (15.9) |

470 (18.5) |

33kg/ 72lb |

VPU-E20 VPU-D20 |

|||||||

| KVR-2D2035 | 200(7.87) ×350(13.7) |

200 (7.87) |

350 (13.7) |

185 (7.28) |

305 (12.0) |

196 (7.71) |

370 (14.5) |

34kg/ 74lb |

|||||

| KVR-2D2050 | 200(7.87) ×500(19.6) |

500 (19.6) |

465 (18.3) |

520 (20.4) |

49kg/ 108lb |

||||||||

| KVR-2D3060 | 300(11.8) ×600(23.6) |

300 (11.8) |

600 (23.6) |

285 (11.2) |

545 (21.4) |

296 (11.6) |

620 (24.4) |

88kg/ 194lb |

|||||

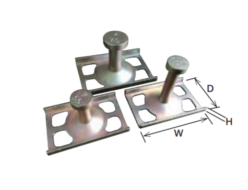

※Clamp parts are included.

| KVR-H1018 | 100(3.93) ×175(6.89) |

100 (3.93) |

175 (6.89) |

20 (0.78) |

72(2.83) | 125(4.92) | P=8 (0.31) |

96 (3.78) |

195 (7.67) |

20 (0.78) |

70 (2.75) |

9kg/ 19lb |

VPU-E10 VPU-E20 VPU-D20 |

| KVR-H1325 | 125(4.92) ×250(9.84) |

125 (4.92) |

250 (9.84) |

92(3.62) | 205(8.07) | 121 (4.76) |

270 (10.6) |

15kg/ 33lb |

|||||

| KVR-H1515 | 150(5.90) ×150(5.90) |

150 (5.90) |

150 (5.90) |

125(4.92) | 105(4.13) | 146 (5.74) |

170 (6.69) |

11kg/ 24lb |

|||||

| KVR-H1530 | 150(5.90) ×300(11.8) |

300 (11.8) |

252(9.92) | 320 (12.6) |

22kg/ 48lb |

※Clamp parts are included.

Kouei is Distributor/Agent of Kanetec.

Other items of Kanetec

Request the quotation for Kanetec

Related Products

-

TAIYO TD Series (Plastic Type) Diaphragm Pump

-

Flex System Anchor With PL

-

Tokyo Keiso MAGMAX® EGM5100C Compact Electromagnetic Flowmeter

-

DIJET CNMA120404, CNMG120408, CNMA120412, CNMA120416 Insert For Cast Iron

-

NFK NK-2300V Vacuum Flexible Hose (JIS Flange Type)

-

KORI SEIKI S-SF4/5/6 Electromagnetic Counter