Kitagawa Corporation.

Kitagawa BRT Series Standard Chuck

Manufacturer: Kitagawa Corporation.

Model: BRT series

Feature:

Gripping accuracy: ≤ 0.01 mm T.I.R.

Reduced jaw-lift

Interchangeable with Kitagawa BT200 / BBT200 series

With Tnut-Plus: jaw repeatability ≤ 0.01 mm T.I.R.

With BR-AJC-M (quick jaw change): faster setup, repeatability ≤ 0.01 mm T.I.R.

Note:

We measure gripping accuracy and repeatability using a test bar positioned 10 mm above the Kitagawa standard soft jaw. We base these values on our internal standards.

For BRT12, both values are ≤ 0.015 mm T.I.R.

Specification

| Model | BRT06 | BRT08 | BRT10 | ||

|---|---|---|---|---|---|

| Through-hole (mm) | 53 | 66 | 81 | ||

| Gripping Range (mm) | Max. | 170 | 210 | 254 | |

| Min. | 20 | 28 | 38 | ||

| Jaw Stroke (Diameter) (mm) | 5.5 | 7.4 | 8.8 | ||

| Plunger Stroke (mm) | 12 | 16 | 19 | ||

| Max. Draw Bar Pull Force (kN) | 15.3 | 23.3 | 32.7 | ||

| Max. Static Gripping Force (kN) | 39 | 60 | 82 | ||

| Max. Speed (min-1) | 6000 | 5000 | 4500 | ||

| Dynamic Gripping Force at Max. Speed (kN) | 16 | 29 | 29.4 | ||

| Moment of Inertia (kg・m2) | 0.05 | 0.13 | 0.32 | ||

| Net Weight (kg) (with Soft Top Jaws) | 12.5 | 21.7 | 34.9 | ||

| Matching Cylinder | SR1453C SS1453K | SR1566C SS1666K | SR1781C SS1881K | ||

| Matching Soft Jaws Note: The package does not include jaw-mounting bolts. | Standard Extra Tall | Standard Extra Tall | Standard Extra Tall | ||

| Tnut-Plus (Option) | TN06PLUS | TN08PLUS | TN10PLUS | ||

Note:

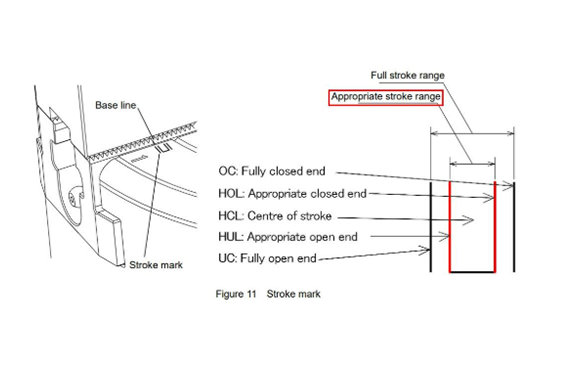

The blue 3D data represents the jaw positions at the fully open (UC) and fully closed (OC) ends for both Parasolid and STEP.

The pink 3D data represents the jaw positions at the centre of stroke (HCL), the appropriate open end (HOL) and the appropriate closed end (HUL) for both Parasolid and STEP.

Jaw stroke

We stamp a stroke mark on the No. 1 jaw part of the body to indicate the jaw stroke position.

When the jaw reaches the open end, the base line of the master jaw aligns with the outer edge of the full stroke range, as shown in Figure 11.

As the operator opens or closes the jaw, the base line moves across the full stroke range. However, the operator must ensure that the base line stays within the appropriate stroke range when the chuck grips a workpiece.