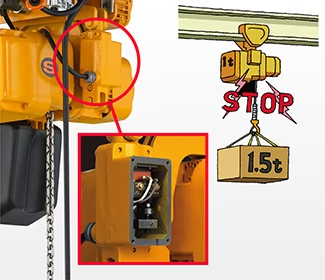

The emergency stop, provided as standard, allows the motor power to be disconnected in an emergency without cutting off the main power supply.

Hoist, Japan, KITO, Lifting

KITO CDER2 Electric Chain Hoists

Product Made in Japan

Manufacturer: KITO

Model: CDER2

Smooth and ergonomic operation, reliable safety, enhanced durability, easier maintenance

Features

- Compact body – lightweight

- Smooth and ergonomic operation

- Reliable safety

- Enhanced durability

- Easier maintenance

- Environmentally friendly

| Capacity | 125 kg, 250 kg |

|---|---|

| Standard Lift | 1.8 m |

| Use | Lifting Up/Down |

| Voltage | 220-230V (50/60Hz), 380-415V (50Hz), 380-440V (60Hz), 500V (50Hz, Pole Change for Dual Speed), 460V (60Hz for Specific Regions) |

Technical Characteristics

Standard Specification

| Voltage | 220-230V (50/60Hz), 380-415V (50Hz), 380-440V (60Hz), 500V (50Hz, Pole Change for Dual Speed), 460V (60Hz for Specific Regions) | Classification | M4, M5, M6 (ISO); 1 Am, 2 m, 3 m (FEM); H4 (ASME) |

|---|---|---|---|

| Motor Insulation | Class B for 220-230V (50/60Hz), 380-440V (60Hz) Class F for 380-415V (50Hz), 380-440V (60Hz) | ||

| Enclosure | Hoist Body – IP55, Push Button Control – IP65 | ||

| Control Voltage | 24V (110V for Specific Regions) | Operating Temperature | -20 to 40℃ (-4 to 104℉) |

| Duty Rating | Single Speed – 60% ED (60 min.) Dual Speed – 40/20% ED (30/10 min.) | Operating Humidity | 85%RH or Less |

Leveraging Today’s Most Advanced Hoisting Technology, This High-performance Hoist Exceeds the Expectations of Even the World’s Most demanding Users.

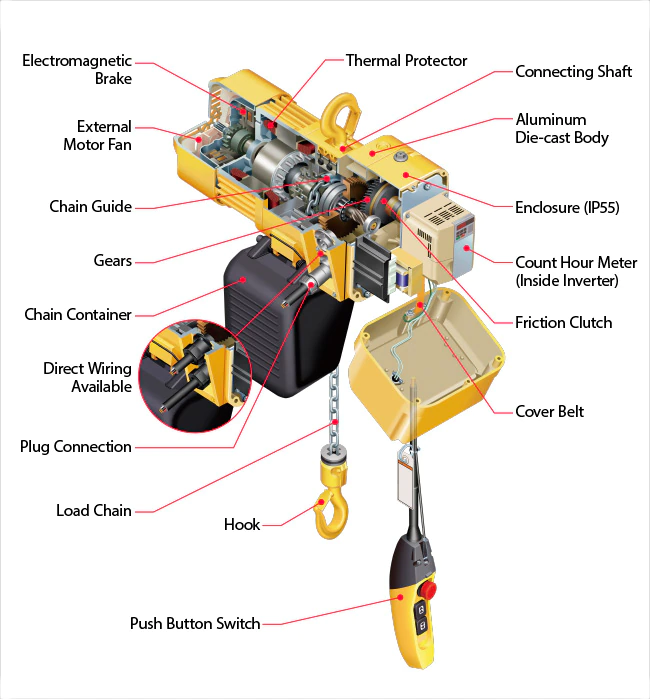

Compact Body – Lightweight

The compact aluminum die-cast body features exceptional rigidity and effective protection against dust and water. It has a simple structure and uses minimal parts, while the fine-tuned load-chain profile better exploits the lighter hoist body weight compared to the previous ER.

Smooth and Ergonomic Operation

- Inverter – Smooth Transitional Speed

The dual-speed inverter delivers smoother movement than the pole change motor, reducing the load swing, while the high-to-low speed ratio can be set to a large value. These allow smooth starts and improve low-speed stops and positioning accuracy. The standard speed ratio is 6:1; adjustable up to 12:1* for lifting and 10:1* for traversing.

* For non-standard speed ratios, please request them when placing order. - Original Push Button Control

Your comfort and safety are assured with push button pendants that are fitted with ergonomic controls and an emergency stop button. - Load Sheave-reduced Vibration

Increasing the number of load sheave pockets helps relieve vibrations produced by the revolving polygonal sheave on the hoist’s body and load chain.

Reliable Safety: Friction Clutch and Upper-lower Limit Switch

- Long-life Friction Clutch

The friction clutch prevents damage to the hoist by automatically engaging in the event of an excessive overload. When the friction clutch engages, the motor is allowed to continue turning protecting both you and the hoist. - Durable Upper/Lower Limit Switch

The limit switch stops working if either end of the load chain comes into contact with the hoist body; protecting against unnecessary downtime and service costs. The ER2’s redesigned upper-lower limit switch features enhanced durability and a low-profile design for improved hoist headroom.

Reliable Safety: Thermal Protector and Magnetic Brake

- Thermal Protector

To prevent motor burnout due to excessive usage, a standard thermal protector is installed in the motor. - Magnetic Brake – Failsafe Brake

KITO’s DC-current brake design reduces maintenance costs by eliminating initial drag and responding immediately on stoppage. This also exposes the motor to less torque for ultra-quiet and smooth operation. Unlike voltage brakes, the advanced technology used in KITO’s DC-current brake protects against hoist failure in the event of motor burnout or single-phasing.

>10-year/ 2,000,000 cycle brake warranty

>No adjustment needed

>Electrical failsafe design

Reliable Safety: Emergency Stop

Enhanced Durability: High-end Duty Rating with Unique Motor Frame Fins and Fan Cover

- High-end Duty Rating

The ER2 achieves M6 (ISO)/3 m (FEM) class with a duty cycle of 60% ED. Supporting use under the most demanding environments and conditions, this long-service-life hoist is a heavy-duty product which can also handle high-frequency or long-lift operations. - Unique Motor Frame Fins and Fan Cover

A unique fan-cooled motor with motor frame fins and a fan cover have been combined in this purpose-built design. This design produces a much quieter motor unit as well as enhanced fan cooling capabilities, while the aluminum die-cast motor frame with external motor fan limits any heat-up during frequent operation.

Enhanced Durability: Super-strong, Corrosion- and Wear-resistant Load Chain

KITO’s world-class original super-strong nickel-plated load chain, certified by the German Institute, uses unique technology for exceptional fatigue- and wear-resistance.

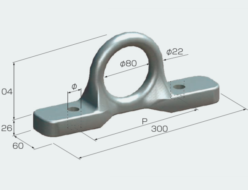

Easier Maintenance: Suspension and Easy Maintenance Control Panel

- Suspension

The hoist can easily be changed from a hook to a lug-mount configuration with external suspension pins on most models. - Easy Maintenance Control Panel

Simple layout of controls and a single swing-down panel. The captured control cover comes complete with a standard wiring diagram for swift on-site access.

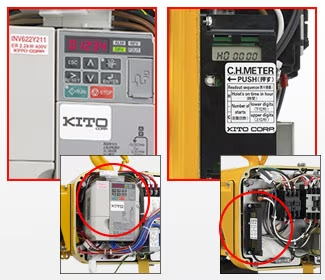

Easier Maintenance: CH (Counter Hour) Meter (Inside Inverter for Dual Speed)

This standard feature shows the cumulative hours of hoist operation and the number of lowering starts on the LCD of the CH meter, which allows the user to maintain the unit based on the frequency of use. By maintaining historical CH meter data, the inspection and replacement periods for gear oil, contactors, brakes and load chains can be efficiently controlled; allowing the equipment to be used with confidence.

Environmentally Friendly

- No Hazardous Substances

Built smarter, eliminating the use of harmful materials. Environmentally friendly and RoHS-compliant. - Energy Saving

Allows energy to be saved due to the reduction in rated current draw compared to the previous ER. - Low-noise

The utilization of the inverter, 4-pole motor as well as the electromagnetic brake, reduces the noise during operation and braking.

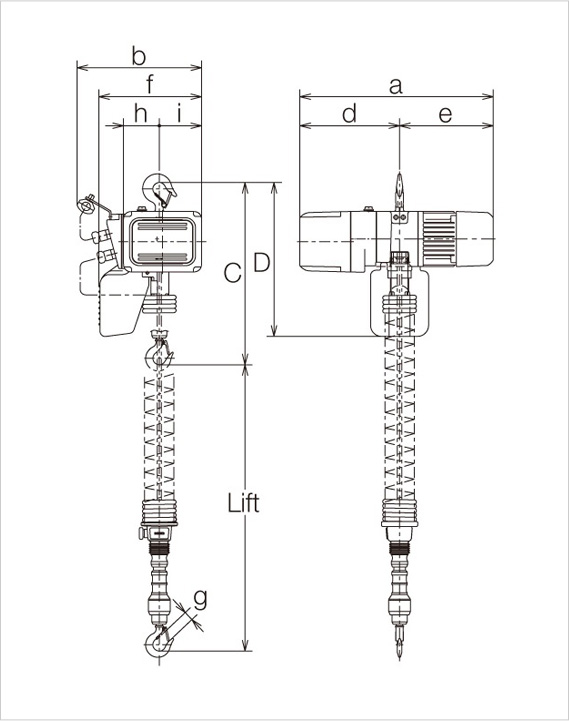

Specifications & Dimensions

Cylindrical Control Dual Speed ‘Inverter’ with Hook Suspension

The dual lifting speed inverter delivers smoother movement than the pole change motor, reducing load swing.

Specifications

※Major capacities example

| Code | Cap. (t) | Std. Lift (m) | Lifting Motor | Lifting Speed* (m/min) | Net Weight (kg) | ||

|---|---|---|---|---|---|---|---|

| Output (kW) | 50/60Hz | ||||||

| High | Low | ||||||

| ER2C001IH | 125kg | 1.8 | 0.56 | Preset | 16.6 | 2.8 | 28 |

| Adjustable | 1.4 | ||||||

| ER2C003IS | 250kg | Preset | 10.8 | 1.8 | |||

| Adjustable | 0.9 | ||||||

- * The high speed is preset to the maximum speed in KITO factory. The speeds are adjustable between High and Low.

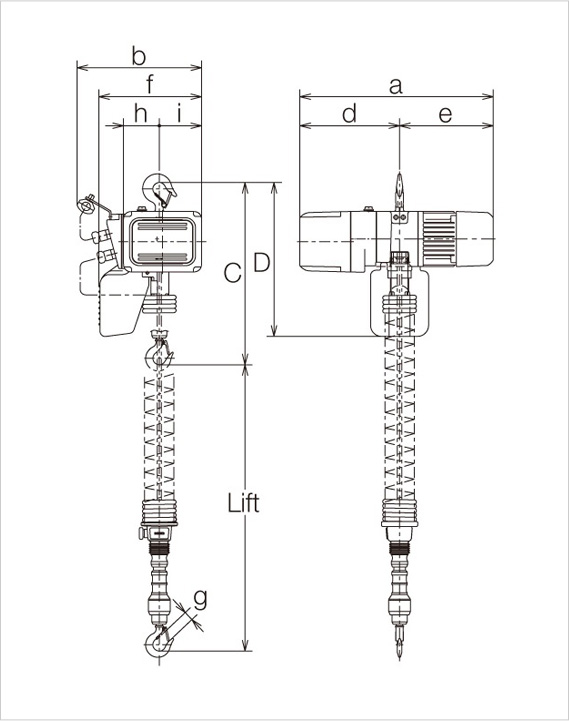

Dimensions (mm)

※Major capacities example

| Code | Headroom: C | D | a(MFC) | b(MFC) | d(MFC) | e |

|---|---|---|---|---|---|---|

| ER2C001IH | 1010 | 430 | 535 (564) | 345 | 276 (305) | 259 |

| ER2C003IS |

- Figures in parentheses are data for mechanical brake with friction clutch.

Cylindrical Control Dual Speed 500V with Hook Suspension

The dual speed pole change delivers slowly.

Specifications

※Major capacities example

| Code | Capacity (t) | Standard Lift (m) | Lifting Motor | Lifting Speed (m/min) | Net Weight (kg) |

|---|---|---|---|---|---|

| Output (kW) | 50Hz | ||||

| ER2C001HD | 125kg | 1.8 | 0.5/0.13 | 14.2/3.5 | 33 |

| ER2C003SD | 250kg | 7.2/1.8 |

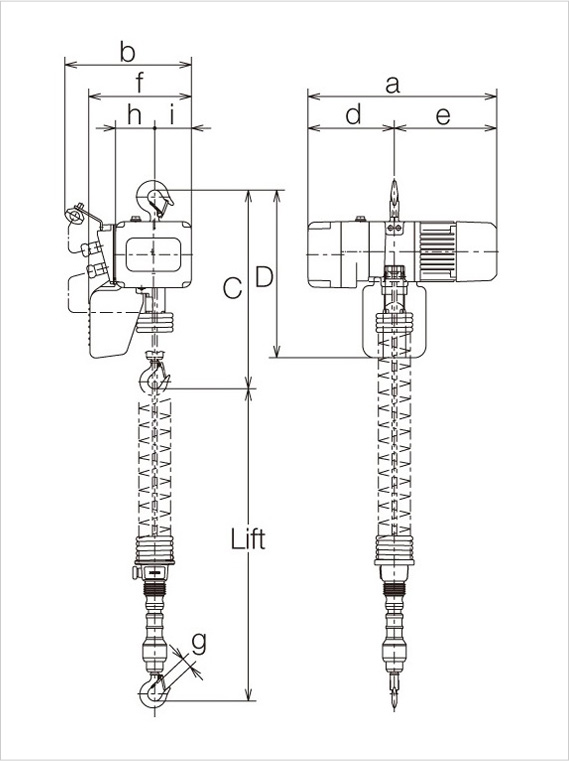

Dimensions (mm)

※Major capacities example

| Code | Headroom: C | a (MFC) | b (MFC) | d (MFC) | e |

|---|---|---|---|---|---|

| ER2C001HD | 1010 | 478 (564) | 321 (345) | 219 (305) | 259 |

| ER2C003SD |

- Figures in parentheses are data for mechanical brake with friction clutch.

Cylindrical Control Single Speed with Hook Suspension

The single speed delivers high speed and contributes operation efficiency.

Specifications

※Major capacities example

| Code | Capacity (t) | Standard Lift (m) | Lifting Motor | Lifting Speed (m/min) | Net Weight (kg) | |

|---|---|---|---|---|---|---|

| Output (kW) | 50Hz | 60Hz | ||||

| ER2C001H | 125kg | 1.8 | 0.56 | 14.1 | 16.9 | 33 |

| ER2C003S | 250kg | 9.1 | 10.9 | |||

Dimensions (mm)

※Major capacities example

| Code | Headroom: C | D | a (MFC) | b (MFC) | d (MFC) | e |

|---|---|---|---|---|---|---|

| ER2C001H | 1010 | 430 | 478 (564) | 321 (345) | 219 (305) | 259 |

| ER2C003S |

- Figures in parentheses are data for mechanical brake with friction clutch.

Options

Mechanical Brake with Friction Clutch

This unique KITO device combines the functions of a friction clutch and mechanical brake for capacities of 5 ton or less and requires additional components. (Request this when placing and ordering hoists.)

Overload Limiter

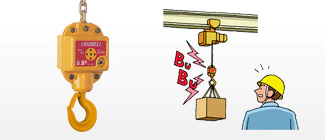

Load Bell

The KITO load bell accurately alerts you when your hoist is overloaded as a cost-effective means of enhancing the safety and efficiency of your operations.