KOGANEI CORPORATION

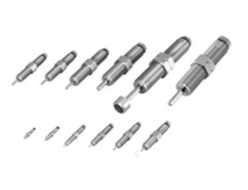

Koganei Compact 2- And 3-Port Media Isolation PVR Series

Manufacturer: KOGANEI CORPORATION

Features

This lineup adds FKM specifications that suit cleaning processes for medical analysis, and the PVR20 model specifically supports these demanding applications. As a result, users gain greater reliability during frequent cleaning cycles. Moreover, the compact valve design delivers a large flow rate, which improves efficiency in medical analysis systems.

In addition, the lineup includes the PVR16 with a 1.6 millimeter orifice and the PVR20 with a 2.0 millimeter orifice, so users can select the optimal size for their process. Furthermore, the rocker type structure minimizes changes to internal volume, which enhances dispensing stability and accuracy. At the same time, the wetted area remains metal free, and this feature significantly improves corrosion resistance.

Additionally, a power saving circuit comes standard, so the system achieves low power consumption without sacrificing performance. As a result, long term operation becomes more economical. Moreover, the design supports a long service life of up to ten million cycles under Koganei testing conditions, which increases overall reliability.

Finally, the lineup offers both solenoid valve types and air operated types for the PVR16 model, which expands application flexibility. In addition, the PVR20 model supports an operating pressure of up to 0.3 megapascals, or 44 psi, so it delivers stable performance across a wide range of medical analysis environments.

Specifications

| Item | PVRA16-2 | PVRA16 | PVR16-2 | PVR16 | PVR20-2 | PVR20 | ||

| Type of valve operation | Air-operated valve (internal pilot type) | Solenoid valve (direct acting type) | Solenoid valve (direct acting type) | |||||

| Valve configuration | Diaphragm type poppet (rocker-type) | Diaphragm type direct poppet (rocker-type) | Diaphragm type direct poppet (rocker-type) | |||||

| Number of ports (Valve function) | 2 (Normally closed (NC)) | 3 | 2 (Normally closed (NC)) | 3 | 2 (Normally closed (NC)) | 3 | ||

| Media | Air, water, pure water, chemical solutionNote 1 | |||||||

| Operating pressure range | Main valve part MPa [psi] | −0.075 to 0.2 [−11 to 29] (COM→NC, NO)Note 2 | −0.075 to 0.3 [−11 to 44] (COM→NC, NO)Note 2 | |||||

| Air-operated part MPa [psi] | 0.15 to 0.30 [22 to 44] | — | ||||||

| Pressure resistant | Main valve part MPa [psi] | 0.3 [44] | 0.45 [65] | |||||

| Air-operated part MPa [psi] | 0.4 [58] | — | ||||||

| Orifice diameter | mm [in.] | 1.6 [0.063] | 2 [0.079] | |||||

| Flow rate characteristics | Base mounting | Water: Cv value of 0.04 Air: C value of 0.16 [dm³/(s·bar)] | Water: Cv value of 0.065 Air: C value of 0.23 [dm³/(s·bar)] | |||||

| Direct piping | Water: Cv value of 0.04 Air: C value of 0.16 [dm³/(s·bar)] | Water: Cv value of 0.065 Air: C value of 0.23 [dm³/(s·bar)] | ||||||

| Capacity in the valve chamberNote 3 | μl | 35 | 60 | |||||

| Amount of leakage | cm³/min | Both inside and outside are 0 (with water pressure) | ||||||

| Response timeNote 4 | ms | — | Under 15 (under 20 if Kalrez) (with air pressure) | Under 15 (with air pressure) | ||||

| Maximum operating frequency | Hz | 2 | ||||||

| Operating temperature range | °C [°F] | 0 to 50 [32 to 122] | ||||||

| Operating temperature range for media used | °C [°F] | 0 to 50 [32 to 122] (non-condensation) | ||||||

| Mass | No sub plate | g [oz] | 7 [0.25] | 20 [0.71] | 22 [0.78] | 42 [1.48] | 43 [1.52] | |

| Sub plate attached | g [oz] | 14 [0.49] | 27 [0.95] | — | 50 [1.76] | — | ||

| Direct piping | g [oz] | — | — | 22 [0.78] | — | 43 [1.52] | ||

| Mounting direction | Any | |||||||