Japan, Kondotec

Kondotec Column-Beam Connection

Made in Japan

Manufacturer: Kondotec

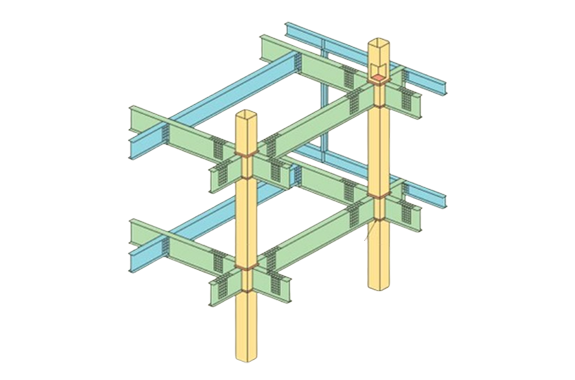

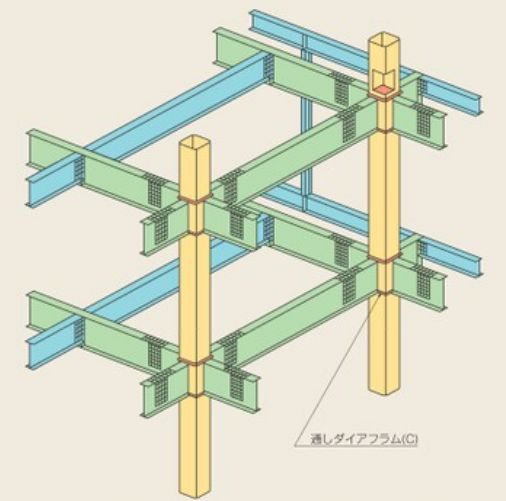

Examples of column and beam joints

In the case of BCR and BCP columns, the diaphragm must have strength equal to or greater than that of the column or beam, so the principle is to use SN material.

Please use SN material for the base as well. (In the case of using SS material for the diaphragm, the column base can be SS material)

Type of Steel for Through Diaphragm

Dimensions of Through Diaphragm

Protrusion method: e = 30mm or greater value of td.

Plate thickness: td (thickness of diaphragm) > tf (thickness of beam flange)

Steel Structure Using Cylindrical Columns

(Through Diaphragm Method)

Points to Note When Performing Welding

Welding Components

Welding method: Back welding with complete base.

Welding position: The principle is to weld from bottom to top.

Number of layers: The principle is multi-layer welding.

Heat input: Desired range is 15KJ/cm to 40KJ/cm.

Interpass temperature: Desired to be below 350°C.

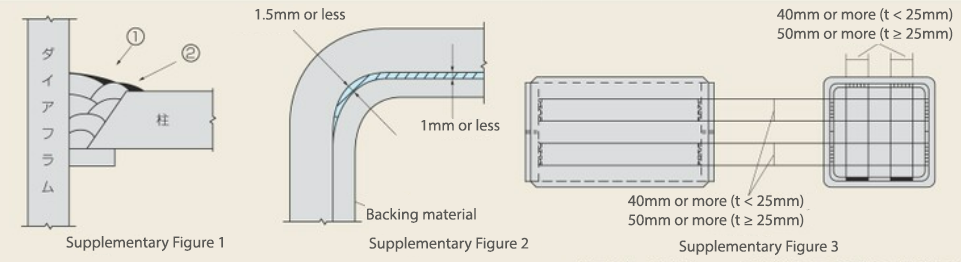

To adjust the shape of the weld joint, when placing filler welds, first place filler weld ①, then place filler weld ②. (Refer to Supplementary Figure 1)

Welding Base

When there is a welding base, keep within the range of Supplementary Figure 2.

Assembly and Welding

Avoid short welds.

Heat input is 15KJ/cm to 20KJ/cm.

Weld length is 40mm or more (t < 25mm), 50mm or more (t ≥ 25mm).

Fillet weld size is from 4 to 6mm.

Avoid welding at corners during assembly (refer to Supplementary Figure 3).

Related Products

-

Chiyoda Seiki Squeeze Tip Type Small Welder For Metal Engraving, Jewelry Processing, And Sheet Metal (For AC)

-

Isolite Insulating Fibermax Board

-

Eight Tool TTR-S9Z Short Arm

-

Watanabe WPD-A20 SPD for signal

-

Eagle Jack (Konno Corporation) G-60C Hydraulic Claw Jack

-

KETT ELECTRIC LABORATORY TX-200 Grainscope