Japan, Krohne

Krohne OPTITEMP TRA-F13 Resistance Temperature Assemblies

Made in Japan

Manufacturer: KROHNE Japan KK

Model: OPTITEMP TRA-F13

Features

- Temperature measurement of solids, liquids and gases

- Thermowell material: 1.4404 / 316L or 1.4571 / 316Ti

- Standard or customised lengths

- Chemically resistant PTFE or similar coating for all wetted parts available

- Different connection heads available (IP54…IP68)

- With optional temperature transmitter

- Available as intrinsically safe: ATEX, IECEx

Typical Applications

- Standard applications with low to medium pressures and flow velocities

- Temperature measurement in pipes and tanks

- Suitable for applications where assemblies complying with DIN standards are required

- Basic measuring tasks in various industries:

Specifications

| General Information | |

|---|---|

| Product type | Temperature assembly |

| Product family name | OPTITEMP |

| Product positioning | For standard applications |

| Product variants | Standard: OPTITEMP TRA-F13 EX: OPTITEMP TRA-F13 Ex |

| Measurement variables | Temperature |

| Measurement principle | Resistance (RTD) |

| Measured media | Liquids, Gases, Solids |

| Assembly with thermowell | Yes |

| Temperature assembly design | DIN-style |

| Thermowell type | Multipart welded |

| Thermowell form (according to DIN 43772) | Form 2F |

| Sensor mounting | Flange |

| Measuring insert replaceable | Yes |

| Measuring insert type | Replaceable spring loaded mineral isolated measuring insert OPTITEMP TR 100 |

| RTD element type | 1 x Pt100, 2 x Pt100 |

| RTD configuration | 2-wire, 3-wire, 4-wire |

| Tolerance class (according to DIN EN 60751) | 1/10 DIN B, A, AA, B |

| Temperature sensor connection type option | Ceramic terminal block, Flying wires, Temperature transmitter |

| Thermowell diameters | Ø9 mm / 0.35″, Ø10 mm / 0.39″, Ø11 mm / 0.43″, Ø12 mm / 0.47″ |

| Thermowell tip design | Straight |

| Mounting point | Pipe, Tank |

| Measuring point | Pipe, Tank |

| Operating Conditions | |

| Process temperature | -200…600°C / -328…1100°F |

| Materials | |

| Wetted parts | Austenitic stainless steel (1.4404/316L), Austenitic stainless steel (1.4571/316Ti) |

| Process Connections | |

| Flange connections | EN (1092-1): DN25…50 ASME (B 16.5): 1…1 1/2 |

| Pressure ratings | EN (1092-1): PN40 ASME (B 16.5): Cl 300# |

| Approvals/Standards | |

| Certificates/Approvals Ex | ATEX, IECEx |

Related Products

-

Eight Tool BHS-9N Ball Point

-

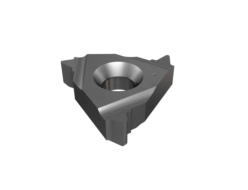

SAKUSAKU 11IR 0.750ISO Insert for Internal Threading ISO Metric Thread 60°

-

Hammer Caster 505SK-RB, 505SK-WR, 505SK-WRB, 505SK-CHR Rubber Wheel Scaffold Caster

-

Chino JU Series Single-Phase Thyristor Regulators

-

Tohnichi SP2-N/SP2-N-MH Preset Torque Wrench

-

Gentos COMBREAKER CB-632D Headlight