Japan, Kurimoto

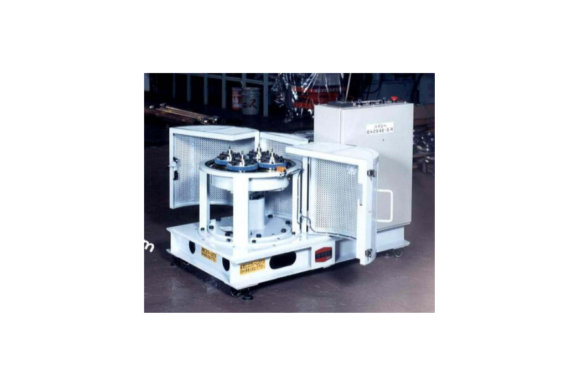

Kurimoto BX254E/BX254E-S/R High G Batch Type High-speed Planetary Mill

Product Made in Japan

Manufacturer: KURIMOTO

Model: BX254E/BX254E-S/R

The Kurimoto High G consists of a main unit which revolves and mill pots which rotate in the same and opposite directions. You should put grinding medium (usually small-diameter balls) and material in the rotating mill pot to move the balls applying centrifugal force generated during revolution and rotation for processing (i.e., grinding).

The name, “Planetary Mill”, is derived from the mill pot’s revolution and rotation like the sun-and-planet motion.

Features

Only one reversible mill available in the world (Source: Our survey)

Powders are processed with large energy from small-diameter balls.

Significantly shortened processing time (up to 1/10 of that with conventional mills).

Low vibration and low noise

Can be upsized. (We can see large-sized mills becoming operational.)

Motion of balls determined through the analysis of computer simulation

Construction

|  |

Typical Flow Sheet

Specifications

| Type | BX254E | BX254E-S/R | BX284E-H | BX384E | BX1144E |

|---|---|---|---|---|---|

| Mill pot | 0.17liters×4pots | 0.2liters×4pots | 0.2liters×4pots | 2.4liters×4pots | 64liters×4pots |

| Heating temperature | —- | —- | Ambient up to 300℃ | —- | —- |

| Hot ai generation unit | —- | —- | By heater, 10kW, 200V, 3 phase, variable speed | —- | —- |

| Motor | 1.5kW, 200V, 3 phase, variable speed | 3.7kW, 200V, 3 phase, variable speed | 3.7kW, 200V, 3 phase, variable speed | 11kW, 200V, 3 phase, variable speed | 200kW, 200V, 3 phase, variable speed |

| Dimensions | 800L× 700W× 1000H | 1300L× 740W× 915H | 1300L× 1600W× 1100H | 1400L× 900W× 1300H | —- |

| Weight | 400kg | 500kg | 550kg | 500kg | 12000kg |

| Rotating/ Revolving direction | Same direction | Same and opposite directions | Same direction | Same direction | Same direction |

Applications

Mechano-chemical reaction

Mechanical alloying (MA)

This is a production method of new materials only with which several kinds of mixed element powders are alloyed only by milling them.

Dry- and wet-process grinding

Dispersion

Particle compounding, and others

Related Products

-

Kanetec KEZF-WS4080 Acshim For Precision Cutting

-

OSC92OT106 3 – Component Load Cell

-

Organo Purified Water Supply Equipment – PWD Series – Pharmaceutical Water Facilities

-

Ascon BK type barrel type and manual machine barrel Blast Cabinet

-

Fujii Denko R-510-D Harness & Lanyard

-

Watanabe RHM [RTD] Indoor Type