Japan, Kurimoto

Kurimoto Horizontal Coarse Grinding Rod Mill

Product Made in Japan

Manufacturer: KURIMOTO

The Rod Mill is the same as the Ball Mill in the construction and available to both of wet and dry processing. Unlike the Ball Mill, however, the Rod Mill uses rods instead of balls as the grinding medium. As a result, its uses are different from those with the Ball Mill. In other words, the Rod Mill gives impact on and grinds coarse particles present between each rod, while no fine particles receive impact and are ground. Therefore, the Rod Mill causes no excessive grinding, enabling you to produce products of relatively sharp particle size distribution curve.

Features

1) Peripheral Discharge Type

1. Wet grinding type (E.P.D. type and C.P.D. type)

This type of mills is used to produce products of relatively coarse particles such as fine aggregate for concrete (e.g. sand making). Normally, it is available not only to produce a variety range of products from feeds of less than 20 to 30 mm in diameter to products of some 5 mm or less in diameter but also make adjustments of particles size of natural sand. The rod mills, which have a discharge port in one end of the shell, are called “End Peripheral Discharge Type” (E.P.D. type as per Fig.1), while those having a discharge port in the center of the shell are called “Center Peripheral Discharge Type” (C.P.D. type as per Fig. 2). Materials are fed through one end opposite to the discharge end on the former type and through both ends of the shell on the latter type. The choice of either the E.P.D. type or the C.P.D. type is to be made in accordance with capacity, product particle size, and conditions before and after the system configuration.

2. Dry grinding type (E.P.D. type)

This type of mills is used to produce products of coarse particles of less than 1 to 5 mm in diameter. You are able to run these mills with elimination of troubles such as sticking or bridging as not only pre-mill to the dry-grinding ball mill but also fine grinding mill for wet coke and ores, and others. The E.P.D. type of mills is mainly used for this application.

Fig. 1 End Peripheral Discharge Type (E.P.D. Type)

Fig. 2 Center Peripheral Discharge Type (C.P.D. Type)

2) Wet-grinding Overflow Discharge Type (O.F.D. Type)

Generally, this type of mills is used for preliminary grinding step before the grinding by ball mill or grinding with less excessive grinding for gravity classification. The rod and ball grinding methods are used for relatively large products crushed, enabling you to attain the open-circuit crushing method and to drastically cut your crushing costs. Furthermore, you are able to minimize the feed ball size to achieve higher degree of efficiency of ball grinding, which is exceedingly useful for a large amount of grinding. This type of rod mills normally feeds balls of less than 15 to 30 mm in diameter to produce 80% product size 500 to 1000m.

Fig. 3 Overflow Discharge Type (O.F.D. Type)

Construction

Specifications

| Size | Inside dia. × Length of shell (mm) | Rod charging amount (tons) | Shell revolution (min-1) | Power consumption (kW) | Motor output (kW) | Capacity (t/h) | |

|---|---|---|---|---|---|---|---|

| A | B | ||||||

| 1224 1230 | 1200×2400 1200×3000 | 5.2 6.5 | 30.5 | 30 37.5 | 37 45 | 10.9 13.6 | 5.7 7.2 |

| 1524 1533 | 1500×2400 1500×3300 | 8.4 11.5 | 26.6 | 51 70.2 | 60 95 | 19.5 26.8 | 10.2 14.1 |

| 1827 1836 | 1800×2700 1800×3600 | 14.0 18.6 | 22.8 | 87 116 | 110 150 | 34.4 46.0 | 18.1 24.2 |

| 2130 2136 | 2100×3000 2100×3600 | 21.0 25.2 | 20.8 | 135 162 | 170 190 | 55.5 66.5 | 29.1 35.0 |

| 2433 2442 | 2400×3300 2400×4200 | 30.7 39.0 | 19.1 | 204 260 | 220 300 | 86.0 108.0 | 45.0 57.0 |

| 2736 2745 | 2700×3600 2700×4500 | 43.0 53.5 | 17.5 | 290 360 | 340 400 | 123.0 155.0 | 65.0 82.0 |

| 3039 3048 | 3000×3900 3000×4800 | 57.4 70.5 | 16.5 | 400 495 | 450 550 | 176.0 218.0 | 93.0 113.0 |

| 3245 3251 | 3200×4500 3200×5100 | 76.0 86.2 | 15.5 | 520 590 | 600 680 | 232.0 264.0 | 121.0 137.0 |

| 3451 3654 | 3400×5100 3600×5400 | 97.5 116.0 | 14.5 13.5 | 670 785 | 750 850 | 304.0 358.0 | 176.0 187.0 |

| 3854 4054 4257 | 3800×5400 4000×5400 4200×5700 | 130.0 145.0 167.0 | 12.8 12.2 11.8 | 860 950 1100 | 1000 1100 1200 | 395.0 450.0 520.0 | 206.0 234.0 276.0 |

Notes

The rod charging amount shall be limited up to 38% of the mill’s internal volume.

Capacities listed in the above table are based on tests with ores of Wi=15KWH/MT and 80% of 15-mm undersized particles, with wet grinding in closed circuit.

A : Capacities are based on tests with grinding material of 80% of 2-mm undersized particles using the Peripheral Discharge Type Rod Mill.

B : Capacities are based on tests with grinding material of 80% of 0.8-mm undersized particles using the Overflow Type Rod Mill.

Mills are available for inside dia. ‘ length of shell (both in increments of 100 mm) other than those listed above.

Applications

1) Mining Industry:

Used for the primary grinding at concentrators and grinding in gravity classification step.

2) Construction Industry

Used to manufacture fine aggregates (sands) in concrete aggregates manufacturing step.

3) Iron Manufacturing Industry

Used to manufacture coke for combustion use and the primary grinding at pelletizing plants of iron ore.

4) Chemical Industry

Used in a wide range of applications like ball mills.

Related Products

-

KONAN NA/NB/NC336 3-port Solenoid Valves For Nuclear Power Plants Universal

-

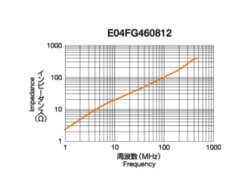

Seiwa E04FG460808 FG Types Ferrite Cores for FPC and FFC

-

Gentos GZ-3STS Tripod Stand For GZ-3 Work Light

-

Honda Kiko VTS(F)/VMS(F) Vertical Shaft Multi-stage Diffuser Pump

-

NPK Ratchet Wrenches

-

Kokosha PJA2/PJB2 Series Side Scuttles Welded Type Gun Metal (JIS Equivalent)