Japan, Matsumoto Kikai

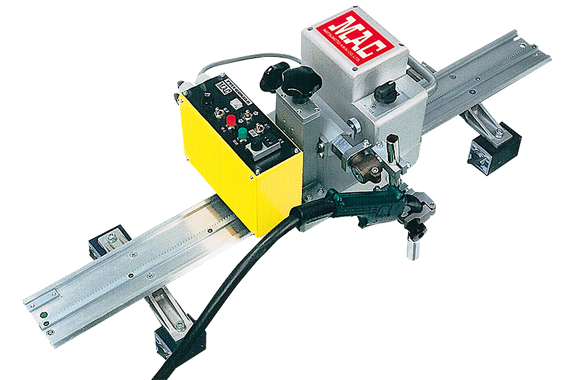

Matsumoto Kikai MAKO-Z0/Z1 Linear Carriage

Product Made in Japan

Manufacturer : Matsumoto Kikai

Model : MAKO-Z0/Z1

The “MAKO-Z” series is a linear welding carriage that runs on aluminum rails. Just press the welding start button, and then straight welding will be performed automatically until the end.

Features

- You can use your own semi-automatic welding machine as it is.

- Compact and lightweight, it is convenient for on-site carrying and setup work. In particular, MAKO-Z1 can be set without tools.

- Easy operation and stable weaving welding. (MAKO-Z1)

- It can handle straight welding in all positions such as downward, sideways, and upward. (MAKO-Z0 faces downward only)

Perfect for downward welding!

(upward welding possible)

MAKO-Z1

● Equipped with 1-axis weaving device!

MAKO-Z0 (zero)

●Lightweight carriage for downward welding only!

■ Configuration

| Product name | MAKO-Z0 | MAKO-Z1 |

|---|---|---|

| Straight running trolley | 1 | 1 |

| Torch fine adjustment unit | 1 | 1 |

| weaving head | 1 | |

| weaving control | 1 | |

| Running rail (standard 2M) | 1 | 1 |

Specifications

●Trolley

| model | MAKO-Z0-H | MAKO-Z1-M |

|---|---|---|

| Driving method | Rail guide Rack & pinion drive | |

| Running speed range | 130~1800mm/min | 40~500mm/min |

| Maximum payload | 10 kg | 5kg |

| Running speed adjustment method | Potentiometer adjustment by thyristor control | |

| electric motor for running | 40W DC motor | |

| Fast forward mechanism | Manual travel with mechanical clutch | |

| Torch position adjustment range | Horizontal 50mm Vertical 100mm Manual adjustment | |

| Automatic stop function | Available Rail top position variable striker (carry built-in bidirectional limit switch) |

|

| Operation function | Power on/off, travel direction (left/right) selection, digital speed controller, welding interlock selection, welding start, welding stop |

|

| Crater processing function | none | |

| Control input power | AC1φ 100V 50/60Hz | |

| power cable length | 3M | |

| Torch switch cable length | 5M | |

| Travel device external dimensions (including weaver) |

348×454×276mm (without weaver) |

379×519×276mm |

| Total mass (including weaver) |

11.5kg (without weaver) |

16kg |

Note) ●The H type can only be used in the horizontal position, and cannot be used in all positions such as standing.

●Please inquire when crater treatment is required or when used for TIG welding.

●Specifications are subject to change without notice, so please inquire when placing an order.

Weaver

| model | WV-8A (for MAKO-Z1) |

|---|---|

| Amplitude times | 30 to 150 times/min |

| amplitude | ±5.1° |

| plunge | – |

| Amplitude trajectory | pendulum |

| Amplitude adjustment method | Continuously variable from manual knob 0 |

| Plunge amount adjustment method | – |

| stop mechanism | selection switch |

| Stop time | 0 to 1.0 seconds continuously variable |

| Stop position selection | 3-point independent adjustment of right, center and left |

| Operation function | Power on/off, run on/off, speed regulator, stop on/off, right stop regulator, center stop regulator, left stop regulator |

| weaver head mass | 2.7kg |

Note) ●Specifications are subject to change without notice, so please inquire when placing an order.

●Rail for running

| rail dimensions | W100×L2000mm aluminum profile |

|---|---|

| rail fixed | 6 permanent magnets |

| magnet attraction | 100kg/piece |

| Rail connection method | Combined tightening with hook fittings and knobs (no tools required) |

| mass | 12kg |

Note) ●L1000mm rail is also available as an option. (With 4 permanent magnets, rail weight 7 kg)

●Attraction force is for a mild steel plate with a plate thickness of 6 mm or more and a clean, smooth surface.

●Specifications are subject to change without notice, so please inquire when placing an order.