Japan, Matsumoto Kikai

Matsumoto Kikai PCM-215/330/445A CNC Pipe Automatic Cutting Equipment

Product Made in Japan

Manufacturer : Matsumoto Kikai

Model : PCM-215/330/445A

Features

- Automatically calculates and cuts the shape of the end pipe joints of steel pipes used for piping such as pipe structures or sleeve pipes.

- The cutting speed is much faster than manual or cutting type, and it is very efficient.

- Since high-precision continuous cutting can be performed, there is no need for grinder work after manual cutting.

- Simply enter the pipe diameter, cutting speed, etc., and press the “Start” button to start automatic cutting.

- A combination of high-performance AC servo motor and computer control has realized full digital control.

- A wide variety of options are available to quickly respond to special specifications. In addition, we can also support interfaces for plasma cutting machines and gas cutting according to pipe materials.

- Thanks to a mechanism that boasts a proven track record over many years, the main body of the device is robust and maintainability is extremely good.

PCM-215 PCM-330

● 2 axes (rotation, left and right) ● 3 axes (rotation, left and right, θ swing)

● Pipe diameter 150A size compatible ● Bevel cutting, miter cutting possible ● Pipe diameter 300A size compatible

PCM-445A (4 axes)

●4 axes (rotation, left/right, θ swing, up/down)

●Up to 99 cutting conditions can be set and stored.

●Drilling and cutting can be performed simply by calling the job number.

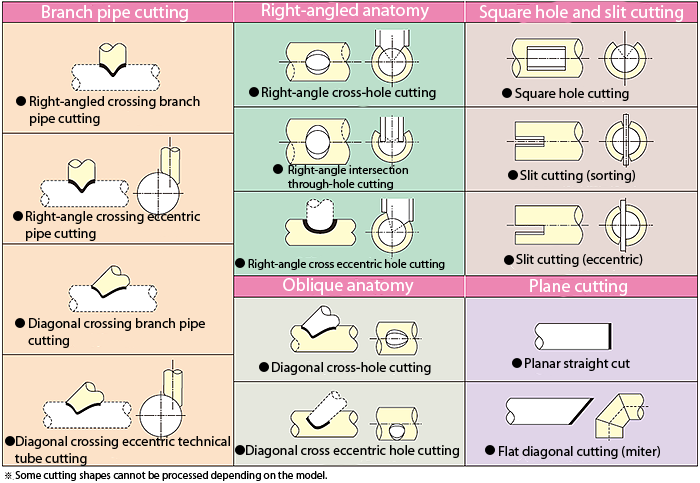

Cutting shape

Pipe sizes that can be processed

△ mark: Option

| model | PCM-215 | PCM-330 | PCM-445A | |

|---|---|---|---|---|

| outer diameter | φ34~~165.2mm | φ60.5~318.5mm | φ60.5~457.2mm | |

| Maximum payload | 150kg | 500kg | 1000kg | |

| thickness | plasma | 2.3 to 12mm (requires 6mm or more pre-drilled hole) |

2.3 to 25 mm (17 mm or more pre-drilled hole required) |

|

| gas | – | △ (5 to 50 mm) | ||

| length | 500-6000mm | 600-6000mm | 600~6000mm (△12000mm) |

|

Configuration

△ mark: Option

| model | PCM-215 | PCM-330 | PCM-445A |

|---|---|---|---|

| Cutting machine body | 1 set | 1 set | 1 set |

| plasma cutting machine | 1 set | 1 set | 1 set |

| gas cutting machine | – | △ | △ |

| receiving roller | 1 set (portable type) | 2 types | 3 types |

| Receiving roller rail | – | 1 set (3m) | 1 type (6m) / △ (12m) |

| Scribing spot marker |

1 set (light projector) | 1 set (light projector) | Not required for full automation |

| data editing computer | △ | ||

Standard specifications

△ mark: Option

| model | PCM-215 | PCM-330 | PCM-445A |

|---|---|---|---|

| cutting speed | Max.2000mm/min | ||

| Number of control axes | 2 axes (rotation/left/right) |

3 axes (rotation, left/right, θ swing) |

4 axes (rotation, left/right, θ swing, up/down) |

| Left/right movement stroke | 400mm | 600mm | 5500mm |

| vertical movement stroke | – | – | 400mm |

| Back-and-forth movement stroke | – | – | – |

| Swing stroke (θ axis) | – | ±45° | ±45° |

| Swing stroke (α axis) | – | – | – |

| Chuck method | 3 claw hollow scroll type | ||

| Chuck electric opening/closing device | – | △ | △ |

| Cutting method | plasma | Plasma (△ gas) | Plasma (△ gas) |

| Power-supply voltage | AC3φ200V 50/60Hz | ||

Note) ●Specifications are subject to change without notice, so please inquire when placing an order.

Functional specifications

△ mark: Option ○ mark: Standard

| model | PCM-215 | PCM-330 | PCM-445A | |

|---|---|---|---|---|

| standard equipment | input method | MDIs | MDIs | MDIs |

| Cutting speed automatic adjustment function | ○ | ○ | ○ | |

| Torsion angle setting function | ○ | ○ | ○ | |

| Program memory function | △99 conditions | ○99 conditions | ||

| Memory card (SD) registration function |

△ | △ | △ | |

| Pipe upper surface sensing function | – | – | ○ | |

| Fixed angle bevel function | – | ○ | ○ | |

| Fixed point bevel function | – | ○ | ○ | |

| cutting function | Plane straight cut / Plane oblique cut | ○ | ○ | ○ |

| Plane diagonal cut (miter) | – | ○ | ○ | |

| right angle cross branch cut | ○ | ○ | ○ | |

| Diagonal cross branch pipe cutting | ○ | ○ | ○ | |

| right angle cross hole cutting | ○ | ○ | ○ | |

| Diagonal cross hole cutting | ○ | ○ | ○ | |

| Right angle cross eccentric branch pipe cutting | ○ | ○ | ○ | |

| Diagonal cross eccentric branch pipe cutting | ○ | ○ | ○ | |

| Right angle cross eccentric hole cutting | ○ | ○ | ○ | |

| Diagonal cross eccentric hole cutting | ○ | ○ | ○ | |

| square hole cutting | ○ | ○ | ○ | |

| Slit cutting (sorting) | ○ | ○ | ○ | |

| Slit cutting (eccentric) | ○ | ○ | ○ | |

Note) ●Specifications are subject to change without notice, so please inquire when placing an order.

●Custom design is possible. Please contact us for details.

Related Products

-

Organo D-4 WⅡ Commercial Water Purifier

-

TONE TW7 Square Drive Unit (Short Type)

-

Honda Kiko HCS/HC Stainless Pumps

-

Kyowa UI-10A Input Adapter for Strain Gauge Transmitter PCD-430A Sensor Interface

-

NDV Pneumatically Operated Valve (double-acting) YWN1300 type Y-Shaped 3-Way Ball Valves (Y300 type)

-

TSURUMI PUMP PARTS: BEARING Parts & Accessories