Bridge Work, Concrete Vibrator, Japan, Meiko Engineering, Pipe, Rubber

Meiko Engineering Expansion Joint

Product Made in Japan

Manufacturer: MEIKO ENGINEERING

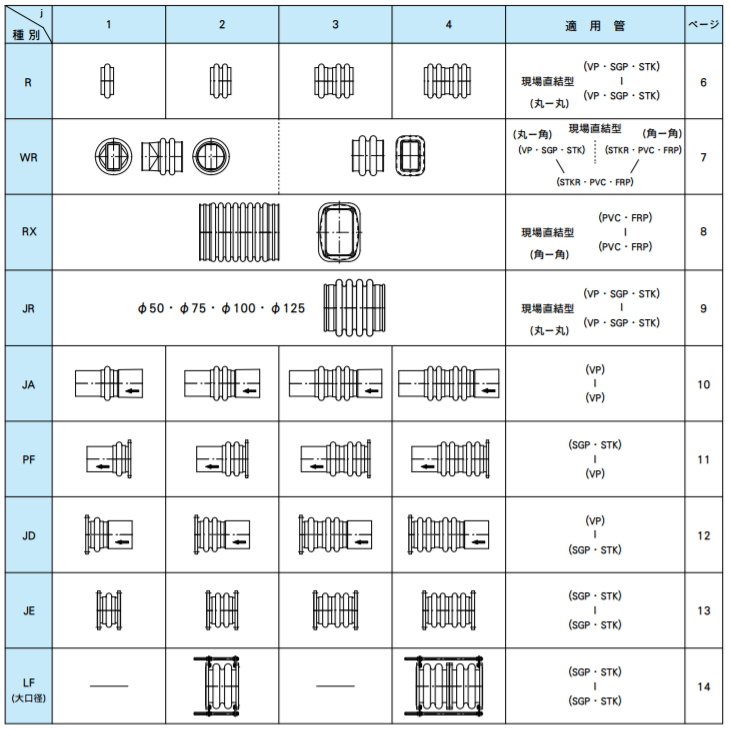

Clasification

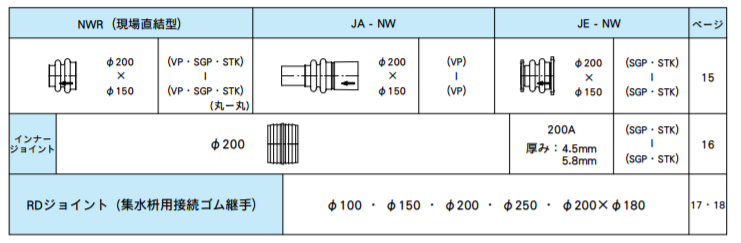

It is “φ 200 A type” attached to the Hanshin Expressway No. 15 Sakai line in 1979, Hanshin University.

Even now after the earthquake, its function still works well. (Taken in March 2000)

Under the high temperature from the atmosphere and the local climate as well as the high vibration from various means of transportation, it is really hard for pipes to tolerate all of these.

That is the reason why MEC joint is developed to protect pipes from such troubles.

This is a vibration isolation / elastic rubber joint for a closed system.

And we have several different types of expansion joint ranging from φ50 to φ550, such as round-angular type, rectangular type, PVC, FRP, steel pipes etc.

Main function

◎ MEC joints have enough strength to connect two pipes together. However, you should set up the pipe appropriately according to the standard value because if not, the elastic rubber will easily come off from the original place.

◎ In terms of flange type products, tighten the bolts sequentially in the diagonal direction so that the bolts are not tightened one by one.

Please tighten it 3 times until you feel tight enough.

Tightening strength is generally controlled by a torque meter.

Tightening torque is to evaluate the standard value of the packing maker manufacturer.

If it does not match this standard value, leakage may occur or PVC can be damaged.

◎ When there is the congealed waters in the drain pipe due to heavy rain etc., the elastic rubber joint may fall off, or the pipe might break down.

Material Standard

| Rubber material specification (EPDM) | ||

| Normal state physicality | Item | Standard value |

| Kataca (HS) | 050±5 | |

| Tensile strength (MPa) | More than 10 | |

| Extension (%) | More than 400 | |

| Compression set test (100 ° C. × 70 H) (%) | Less than 50 | |

| Heat aging test (100 ° C. × 70 H) | Katasa change (HS) | +10 |

| Tensile strength change rate (%) | -20 | |

| Elongation change rate (%) | -30 | |

Test method: … JIS K 6259

Ozone test condition … Constant current electrolysis method

Concentration = 50 ± 5 pphm

Temperature = 40 ± 2 ° C

Elongation = 20% Static

Time = 24 hrs

Test results …… Kiretsunashi

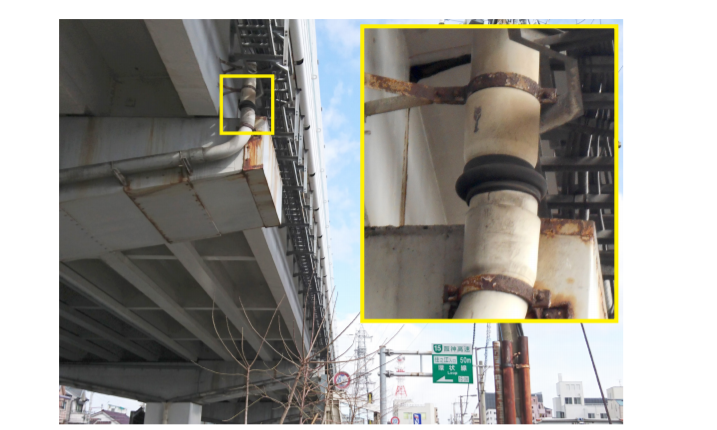

Cold resistance

As rubber gets cooler, it gets hard and brittle because it was made from a type of polymer with natural rubber. So you need no worry because it can stretch under the very low temperature.

Low temperature operating temperature range of various polymers

Part name and material

| No. | Product name | Material | Note |

| 1 | Stretch rubber | EPDM | |

| 2 | A guide plate | EPDM | |

| 3 | Pipe | PVC | VP pipe |

| 4 | Socket | PVC | VP pipe processed product |

| 5 | Flanged with pipe | SS400,SGP | Loose flange (galvanized) |

| 6 | Idle pipe | SUS304TP | |

| 7 | Packing | EPDM | |

| 8 | Anti-foaming body | Urethane foam | |

| 9 | Mounting band · stop | SUS304 | |

| 10 | Tightening band · Hexagon socket head bolt | AC・SUS304 (bolt) | |

| 11 | Dummy pipe | PVC | VP pipe |

| 12 | Reinforcing ring | SUS304 | |

| 13 | Cover rubber | EPDM |

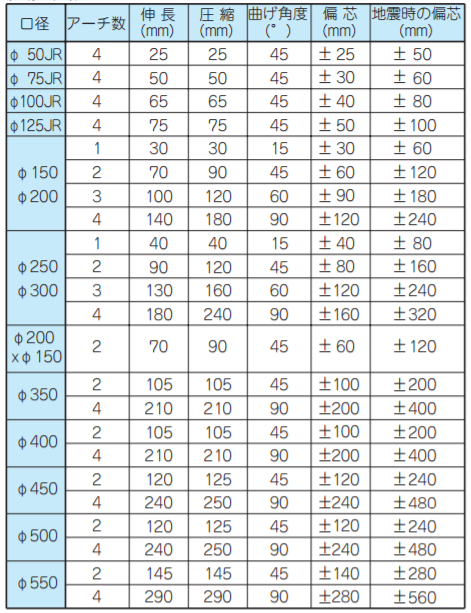

Performance standard

Common types

Application

Related Products

-

Chiyoda Seiki TKR-200 series Medium Flow Self-powered Pressure Regulator (Primary pressure: 20.0 MPa or less/adjustment pressure 0.2 to 1.5 MPa, standard flow rate: 280 m3/h・Air)

-

Electromagnetic Sieve Shaker

-

KORI SEIKI P-Type Counters

-

Asahi Bagnall PAC Insulator

-

Tohnichi TCR Torque Sensor

-

Kaneko Sangyo SLIM Series Magnet Float Liquid Level Gauges