Product Made in Japan

Manufacturer: Miyakawa

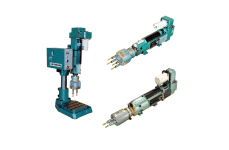

Model: QT1, QT2

QT1 type

|

- High speed, high precision machining is possible.

- It is a tap unit (3 to 10 times the conventional type) that can process at high speed.

- It is a lightweight, compact unit.

- Machining time can be shortened by fast forward, pitch feed, fast forward 3-speed feed.

- High-speed continuous cycle operation of 40 times per minute is possible.

- Changing the feed pitch is done by replacing “change gear box”.

- We adopt energy saving, high efficiency driving motor.

- The same installation as the AF drill unit is possible.

- It has a simple structure and has few failures and is economical.

|

| ※ Multi-axis is optional item |

Geometry

|

A |

B |

C |

D |

E |

F |

G |

H |

I |

K |

L |

M |

Main shaft end taper |

| QT1 |

568 |

twenty five |

35 |

twenty five |

150 |

149 |

121 |

42 |

60 |

Ten |

182 |

242 |

JT No. 1 |

Performance specification

| Model |

Cutting rotation speed

min – 1 |

Maximum tapping capacity by axis number |

Fast-forward rotation speed |

Main spindle stroke range |

Lead feed range |

Fast forward range |

Drive motor |

| 1 axis |

2 axes |

3 Axis |

4 axes |

| Carbon steel |

cast iron |

Aluminum |

Carbon steel |

cast iron |

Aluminum |

Carbon steel |

cast iron |

Aluminum |

Carbon steel |

cast iron |

Aluminum |

| min-1 |

mm |

mm |

mm |

W |

| QT 1 – 400 |

400-4000 |

M4.5 |

M6 |

M7 |

M3.5 |

M4.5 |

M5.5 |

M3 |

M4 |

M4.5 |

M2.6 |

M3.5 |

M4 |

4000 |

20 – 60 |

0 – 40 |

20 – 40 |

400 |

| QT 1 – 270 |

270-2700 |

M5.5 |

M7 |

M8 |

M4 |

M5.5 |

M6 |

M3.5 |

M4.5 |

M5.5 |

M3 |

M4 |

M4.5 |

2700 |

| QT1-180 |

180-1800 |

M6 |

M8 |

M9 |

M5 |

M6 |

M7 |

M4 |

M5.5 |

M6 |

M3.5 |

M5 |

M5.5 |

1800 |

note

- The maximum calculation value is stated for tapping capacity.

- Because there are some differences according to the following use conditions, please use as a guide only.

- Since the cutting speed is determined by the type of tap and the material to be cut, we recommend using the recommended rotation speed of the tap manufacturer.

- We recommend that you select units that are one rank higher in capability selection.

- If you install a multi-axis attachment (deceleration type), it will be more powerful, so please contact us.

|

terms of use

- Types of taps (hand, spiral, points etc Calculation with cutting tap

- Tap lifespan (change in sharpness)

- Cutting material, diameter of lower hole

- Type and state of use of cutting oil

- For rolling tapping, please contact us.

QT type 2

|

- High speed, high precision machining is possible.

- It is a tap unit (3 to 10 times the conventional type) that can process at high speed.

- It is a lightweight, compact unit.

- Machining time can be shortened by fast forward, pitch feed, fast forward 3-speed feed.

- High-speed continuous cycle operation of 40 times per minute is possible.

- Changing the feed pitch is done by replacing “change gear box”.

- We adopt energy saving, high efficiency driving motor.

- The same installation as the AF drill unit is possible.

- It has a simple structure and has few failures and is economical.

|

| ※ Multi-axis is optional item |

Geometry

|

A |

B |

C |

D |

E |

F |

G |

H |

I |

K |

L |

M |

Main shaft end taper |

| QT2 |

714 |

40 |

43 |

27 |

135 |

305 |

144 |

60 |

80 |

12 |

236 |

296 |

JT No. 6 |

Performance specification

|

Model |

Cutting rotation speed

min – 1 |

Maximum tapping capacity by axis number |

Fast-forward rotation speed |

Main spindle stroke range |

Lead feed range |

Fast forward range |

Drive motor |

| 1 axis |

2 axes |

3 Axis |

4 axes |

| Carbon steel |

cast iron |

Aluminum |

Carbon steel |

cast iron |

Aluminum |

Carbon steel |

cast iron |

Aluminum |

Carbon steel |

cast iron |

Aluminum |

| min-1 |

mm |

mm |

mm |

W |

| QT 2 – 240 |

240-2400 |

M7 |

M9 |

M10 |

M5.5 |

M7 |

M8 |

M4.5 |

M6 |

M7 |

M4 |

M5.5 |

M6 |

2400 |

25-100 |

0-75 |

25-50 |

750 |

| QT 2-150 |

150-1500 |

M8 |

M10 |

M12 |

M6 |

M8 |

M9 |

M5 |

M7 |

M8 |

M4.5 |

M6 |

M7 |

1500 |

| QT 2-100 |

100-1000 |

M9 |

M12 |

M14 |

M7 |

M9 |

M10 |

M6 |

M8 |

M9 |

M5.5 |

M7 |

M8 |

1000 |

note

- The maximum calculation value is stated for tapping capacity.

- Because there are some differences according to the following use conditions, please use as a guide only.

- Since the cutting speed is determined by the type of tap and the material to be cut, we recommend using the recommended rotation speed of the tap manufacturer.

- We recommend that you select units that are one rank higher in capability selection.

- If you install a multi-axis attachment (deceleration type), it will be more powerful, so please contact us.

|

terms of use

- Types of taps (hand, spiral, points etc Calculation with cutting tap

- Tap lifespan (change in sharpness)

- Cutting material, diameter of lower hole

- Type and state of use of cutting oil

- For rolling tapping, please contact us.

|

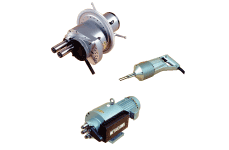

QT type option

|

- The controller consists of a control unit incorporating the basic operation and a brushless motor inverter.

- You can drive immediately with a simple connection with this machine.

|

|

Configuration example of QT unit and optional item

- QT unit QT 1 – 270

- Stand (option)

- Control unit (option)

- Multi-axis 2E 077 C-6 (option)

|

Multi-axis Attachment (Option)

|

A (C-10) |

B (C-6) |

C (C-4) |

D |

E |

Unit (AF) |

| QT-1 |

177 |

161 |

165 |

42 |

JT No. 1 |

AF-1 |

| QT-2 |

168.5 |

152.5 |

156.5 |

60 |

JT No. 6 |

AF2 |

| ※ AF unit shared function |

|