Japan, Nachi

Nachi NRP Series Power Package

Made in: Japan

Manufacturer: NACHI

Model: NRP series

Features

Energy-saving

The amount of power consumed is 50W (*1), approximately 95% down

Low noiz

Low heat-generating

The rise of oil temperature to room temperature +7°C (*1)

Compact

Installation space 35% down (our standard unit ratio)

Leak compensation

At time of accumulator (option) installation

→ Even when stopped, it maintains the pressure, so the energy-saving effect is greater

Specifications of NRP Series

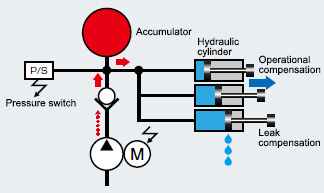

Example system configuration (machining center cramp)

The unit accumulates pressure in the accumulator and stops the electric motor with the set upper pressure limit of the pressure switch. Using the oil pressure accumulated in the accumulator, the unit maintains the pressure of the circuit and carries out and , and when it reaches the set lower pressure limit of the pressure switch it is re-started. (Start and stop the electric motor at the signal from the pressure switch.)

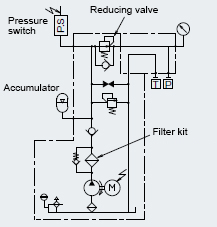

Hydraulic circuit diagram

The pressure switch, accumulator, filter kit, and reducing valve are options. Select these options according to your application.

Package Specifications

| NRP-10-12-10 | NRP-10-24-10 | Remarks | |

|---|---|---|---|

| Pump capacity | 3.0cm3/rev | 5.0cm3/rev | |

| Motor output – No. of poles | 1.2kW-4P | 2.4kW-4P | S3: Repeated operation |

| Rate of loaded operating time (per minute) | 15% (9seconds) | 10% (6seconds) | |

| Tank specification | Resin tank (10 liters) | ||

| Options | |||

| Pressure switch | One output point (open collector) | Fixed pressure type | |

| Accumulator | 0.7 liters | ||

| Reducing valve | Pressure adjustment range: 1.5 – 7.0MPa | ||

| Tank specifications | Steel plate tank (10 liters) | Steel-plate tank has a special design number | |

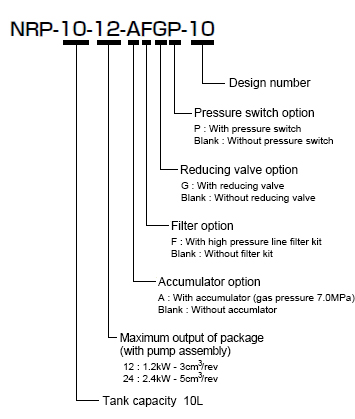

Explanation of model number

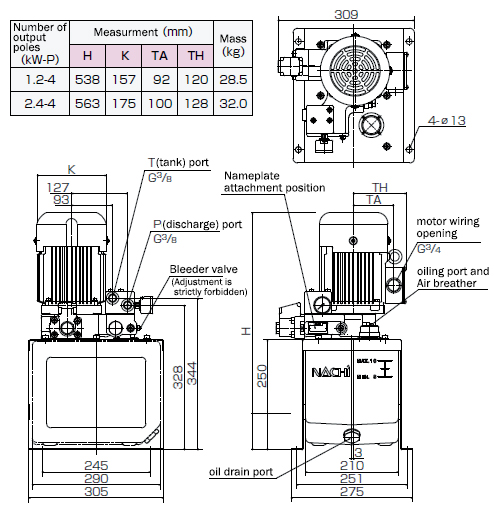

Dimension Table

Precautions for handling

Precautions when operating (procedures that you must comply with)

- The NRP series power package is a hydraulic package for intermittent operations (electric motor ON-OFF). If the load operation time is excessive or a mistaken operational method is used, there is a danger of damage to the device resulting from the heating of the electric motor and hydraulic fluid, so use the unit only after reading the instruction manual carefully.Load operation hour rate 1.2kW-4P···15% 2.4kW-4P···10%

- In order to carry out intermittent operations, it is necessary to set up a pressure switch, etc. inside the circuit and have a circuit that turns the points of contact on the power source side ON and OFF.

- When carrying out an overhaul, release the bleeder valve to let out the pressure inside the accumulator first. (At the time of accumulator installation)

- The accumulator (optional specifications) is filled with nitrogen gas. When discarding an accumulator, be sure to remove the gas first.

- The transportation and installation of accumulators (optional specifications) is subject to regulations so contact our company regarding the details.

Precautions when starting the unit

- Operate the unit after confirming with a fluid level gauge whether the hydraulic fluid inside the tank satisfied the prescribed level (the lower limit value or above).(1) Upper limit: prescribed volume of hydraulic fluid (nominal capacity)

(2) Lower limit: minimum hydraulic fluid level - Connect the electrical wire connections without any mistakes as follows.

Phase sequence of the electric motor side and the power source side In the case of a mistake with the wire connections U → (R)

V → (S)

W → (T)- The electric motor will reverse-rotate and will not discharge the hydraulic fluid from the pump.

- Confirm that the pressure is rising in the pressure gauge attached to the discharge side.

Hydraulic fluid

- General mineral oil type hydraulic fluid equivalent to viscosity grade ISO VG32

Maintenance and Inspection

- Oil temperature : use in a range of 5

60°C.

60°C. - Timing of hydraulic fluid replacement

At the beginning, replace the fluid after three months of operation.

Subsequently, replace the fluid when it is contaminated or after every one year has passed. - Inspection of the inside of the tank and the strainer: every three months.

- Gas sealing of the accumulator (optional specifications) is not possible. Regular replacement will be necessary.

Surrounding environment

- temperature : 5

35°C

35°C - Ensure that water-soluble cutting fluid mist does not get deposited on the unit.

Related Products

-

Tohnichi QLLS/CLLS/PQLLS/PCLLS/TiQLLS Pokayoke Torque Wrench

-

Kamiuchi wireless device Other/Related Machinery

-

KETT ELECTRIC LABORATORY LE-200J Electromagnetic Coating Thickness Tester

-

Super Tool H4000S Tool Set (Plumbing Standard Set) For Professional Use

-

Nachi SV-20-23M Mechanical Surface Broaching Machine

-

Chiyoda Tsusho FR4/6/8/10 Reducer Connector