Japan, NAGANO KEIKI

NAGANO KEIKI GV4_ Glycerine Bath Type Pressure Gauges

Made in Japan

Manufacturer: NAGANO KEIKI

Model: GV4_ Glycerine Bath Type Pressure Gauges for High-Pressure Hydrogen

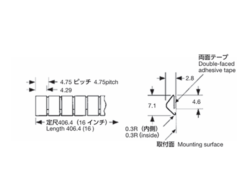

This is a gauge for exclusive use exposed to vibration. Its interior is filled with liquid, preventing vibration of moving parts and wear of interior linkage mechanism, and making maintenance work easier.

Certificate:

Features

+The parts contacting with the liquid and the case are made of stain less steel so that they are excellent in anti-corrosion and environ-mental resistance.

+By equipping a blowout disk, the effect of temperature change on accuracy is reduced, and breakage of glass is prevented in case the Bourdon tube bursts.

+To indicate the working pressure gauges with 60 DIA. and 75 DIA. are provided with a safety mark(green mark) as an option which can be set by an arrow.

*In case of selecting pressure gauge, choose the pressure range which can be used in between 30-65% of full scale, so that the gauge can give its full capacity.

*Also should be confirmed whether the wetted parts material is suit able for the fluid or not.

+By equipping a blowout disk, the effect of temperature change on accuracy is reduced, and breakage of glass is prevented in case the Bourdon tube bursts.

+To indicate the working pressure gauges with 60 DIA. and 75 DIA. are provided with a safety mark(green mark) as an option which can be set by an arrow.

*In case of selecting pressure gauge, choose the pressure range which can be used in between 30-65% of full scale, so that the gauge can give its full capacity.

*Also should be confirmed whether the wetted parts material is suit able for the fluid or not.