Japan, Naniwa

Naniwa Multi Eye Bolt

Product Made in Japan

Manufacturer : Naniwa

Model: Multi Eye Bolt (ME0808C,ME1008C,ME1210C,ME1414C,ME1614C,ME1818C,ME2018C,ME2222C,ME2422C,

ME2728C,ME3028C,ME3632C,ME4236C,ME4842C)

Certified by NETIS-VE

Features

- You can use it safely for horizontal, diagonal, and lifting work, avoiding the dangers associated with conventional JIS eye bolts.

- Since it is possible to use three times the working load of JIS eye bolts, the screw hole drilling on the target object can be made smaller, resulting in cost reduction.

- When handling cargo using two or more multi-eye bolts, please use within the working load range that takes into account the tension increase factor depending on the hanging angle. In addition, when installing this product, installing a thick washer or the like between the seat surface of this product and the cargo handling object is not guaranteed as it will drastically reduce the working load.

- Although it can be used repeatedly, there is a risk of damage due to metal fatigue due to repeated use, so please carry out periodic inspections determined by the customer according to the degree of use (load and frequency).

*Working load (WLL) is the static load that can be applied to one multi-eye bolt.

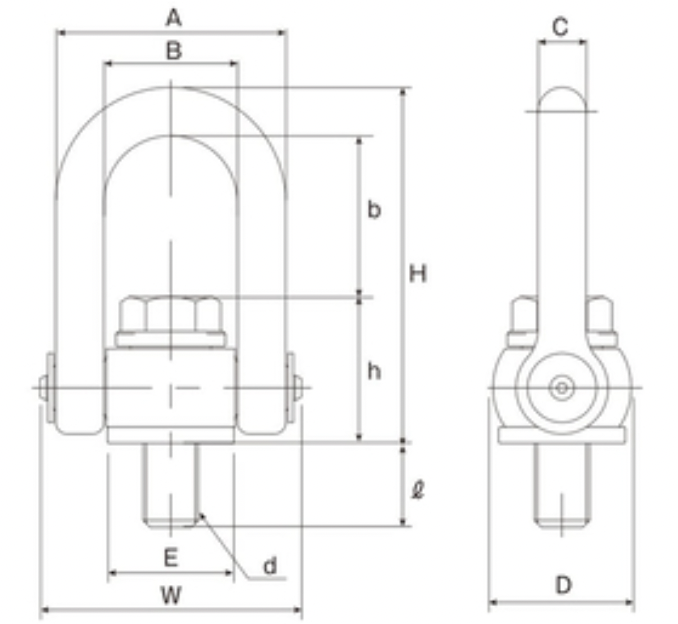

| Product number | Working load Ton(KN) | Mounting bolt d | A | B | C | D | ℓ |

| ME0808C | 0.3(2.94) | M8 | 41 | 25 | 8 | 28 | 11 |

| ME1008C | 0.5(4.90) | M10 | 41 | 25 | 8 | 28 | 16 |

| ME1210C | 0.8(7.85) | M12 | 50 | 30 | 10 | 32 | 21 |

| ME1414C | 1.2(11.77) | M14 | 65 | 37 | 14 | 42 | 27 |

| ME1614C | 1.6(15.69) | M16 | 65 | 37 | 14 | 42 | 27 |

| ME1818C | 1.8(17.65) | M18 | 83 | 47 | 18 | 50 | 31 |

| ME2018C | 2.5(24.52) | M20 | 83 | 47 | 18 | 50 | 31 |

| ME2222C | 3.1(30.40) | M22 | 102 | 58 | 22 | 60 | 37 |

| ME2422C | 3.6(35.30) | M24 | 102 | 58 | 22 | 60 | 37 |

| ME2728C | 4.8(47.07) | M27 | 128 | 72 | 28 | 75 | 50 |

| ME3028C | 5.8(56.87) | M30 | 128 | 72 | 28 | 75 | 50 |

| ME3632C | 8.0(78.45) | M36 | 154 | 90 | 32 | 90 | 57 |

| ME4236C | 10.0(98.06) | M42 | 176 | 104 | 36 | 105 | 67 |

| ME4842C | 15.0(147.00) | M48 | 200 | 116 | 42 | 120 | 73 |

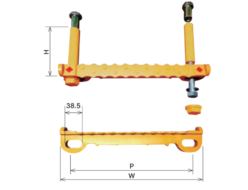

| Product number | b | h | H | E | W | Approximate bolt tightening torque (Kgf・m) | Weight (kg) |

| ME0808C | 33 | 30 | 71 | 24 | 50 | 0.8~1.5 | 0.18 |

| ME1008C | 32 | 31 | 71 | 24 | 50 | 1.0~2.5 | 0.19 |

| ME1210C | 40 | 38 | 88 | 29 | 62 | 1.5~4.0 | 0.35 |

| ME1414C | 47 | 48 | 109 | 36 | 79 | 4.0~10.0 | 0.72 |

| ME1614C | 47 | 48 | 109 | 36 | 79 | 4.0~10.0 | 0.75 |

| ME1818C | 60 | 57 | 135 | 45 | 100 | 7.0~15.0 | 1.32 |

| ME2018C | 60 | 57 | 135 | 45 | 100 | 7.0~15.0 | 1.38 |

| ME2222C | 72 | 63 | 157 | 56 | 121 | 10.0~25.0 | 2.31 |

| ME2422C | 72 | 63 | 157 | 56 | 121 | 10.0~25.0 | 2.38 |

| ME2728C | 90 | 79 | 197 | 70 | 150 | 12.0~35.0 | 4.7 |

| ME3028C | 90 | 79 | 197 | 70 | 150 | 12.0~35.0 | 4.9 |

| ME3632C | 112 | 91 | 235 | 85 | 176 | 15.0~50.0 | 7.6 |

| ME4236C | 130 | 109 | 275 | 100 | 200 | 18.0~60.0 | 11.8 |

| ME4842C | 140 | 127 | 309 | 110 | 226 | 30.0~80.0 | 18.2 |

*Please consult us separately regarding changes in bolt ℓ dimensions. *The shape and specifications of the products listed in this catalog are subject to change without notice due to improvements.

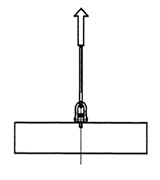

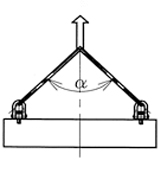

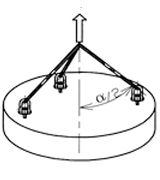

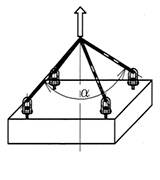

List of basic working loads by suspension method

|

|

|

|

|||

| Number of pieces used | 1 | 2 | 3 or 4 | |||

| Hanging angle α | α=0° | α≦90° | 90°<α≦120° | α≦90° | 90°<α ≦120° |

|

| Mode coefficient M | 1 | 1.4 | 1 | 2.1 | 1.5 | |

| Product number | Working load | Unit: ton | ||||

| ME0808C | 0.3 | 0.3 or less | 0.4 or less | 0.3 or less | 0.6 or less | 0.4 or less |

| ME1008C | 0.5 | 0.5 or less | 0.7 or less | 0.5 or less | 1.1 or less | 0.7 or less |

| ME1210C | 0.8 | 0.8 or less | 1.1 or less | 0.8 or less | 1.7 or less | 1.2 or less |

| ME1614C | 1.6 | 1.6 or less | 2.2 or less | 1.6 or less | 3.4 or less | 2.4 or less |

| ME2018C | 2.5 | 2.5 or less | 3.5 or less | 2.5 or less | 5.3 or less | 3.7 or less |

| ME2422C | 3.6 | 3.6 or less | 5.0 or less | 3.6 or less | 7.6 or less | 5.4 or less |

| ME3028C | 5.8 | 5.8 or less | 8.1 or less | 5.8 or less | 12.2 or less | 8.7 or less |

| ME3632C | 8.0 | 8.0 or less | 11.2 or less | 8.0 or less | 16.8 or less | 12.0 or less |

| ME4236C | 10.0 | 10.0 or less | 14.0 or less | 10.0 or less | 21.0 or less | 15.0 or less |

| ME4842C | 15.0 | 15.0 or less | 21.0 or less | 15.0 or less | 31.5 or less | 22.5 or less |

*In the case of a 4-wire suspension, the suspension angle is the angle of the opposing wires, etc. in the diagonal direction. *Due to development and improvement, specifications may change without notice. Round down to the second decimal place

Related Products

-

Yutani D, DH Impact Screwdrivers(Pistol Rear Exhaust Type)

-

Chiyoda Tsusho FR4/6/8/10/12 Union Y Connector

-

Kurimoto Stainless Duct

-

Flex System Amenity Step (Electric Leakage Prevention Type)

-

Kyowa BER-S-500KP17SA1 BER-S-17SA1 Wall-surface Soil Pressure Transducer

-

Horiuchi FB Compact Type Cylinder CS Series