Japan, Naniwa

Naniwa Multi EyeBolt Hybrid

Product Made in Japan

Manufacturer : Naniwa

Model: Multi EyeBolt Hybrid(HBM2416,HBM2420,HBM3020,HBM3024,HBM3624,HBM3630,HBM4230,HBM4236,

HBM4836,HBM4842,HBM6448)

We have evolved the multi-eye bolt. Compared to conventional multi-eye bolts, you can choose from a wide variety of working loads.

The product has a small body, is lightweight, easy to use, and is designed with work efficiency in mind.

Features

- When handling cargo using two or more multi-eyebolt hybrids, please use them within the working load range that takes into account the tension increase factor due to the hanging angle. Additionally, when installing, inserting thick washers, etc. between the seat of this product and the cargo handling object will drastically reduce the working load and is not guaranteed.

- Although it can be used repeatedly, there is a risk of damage due to metal fatigue due to repeated use, so please carry out periodic inspections determined by the customer according to the degree of use (load and frequency).

- Please replace the mounting bolts regularly or inspect them for cracks using magnetic particle inspection to ensure safety.

*Working load (WLL) is the static load that can be applied to one multi-eyebolt hybrid.

| Product number | Working load Ton(KN) | Mounting bolt d | A | B | C | D | L |

| HBM2416 | 2.0(19.6) | M24 | 65 | 37 | 14 | 42 | 35 |

| HBM2420 | 2.8(27.4) | M24 | 83 | 47 | 18 | 50 | 35 |

| HBM3020 | 3.2(31.8) | M30 | 83 | 47 | 18 | 50 | 45 |

| HBM3024 | 4.2(41.2) | M30 | 102 | 58 | 22 | 60 | 45 |

| HBM3624 | 4.6(45.9) | M36 | 102 | 58 | 22 | 60 | 55 |

| HBM3630 | 6.5(63.7) | M36 | 128 | 72 | 28 | 75 | 55 |

| HBM4230 | 7.0(68.6) | M42 | 128 | 72 | 28 | 75 | 65 |

| HBM4236 | 8.5(83.3) | M42 | 154 | 90 | 32 | 90 | 65 |

| HBM4836 | 9.0(88.2) | M48 | 154 | 90 | 32 | 90 | 70 |

| HBM4842 | 12.0(117.7) | M48 | 176 | 104 | 36 | 105 | 70 |

| HBM6448 | 20.0(196.0) | M64 | 200 | 116 | 42 | 120 | 90 |

| Product number | b | h | H | E | W | Approximate bolt tightening torque (Kgf・m) | Own weight (kg) |

| HBM2416 | 45 | 50 | 109 | 36 | 79 | 10.0~25.0 | 0.83 |

| HBM2420 | 58 | 59 | 135 | 45 | 100 | 10.0~25.0 | 1.42 |

| HBM3020 | 58 | 59 | 135 | 45 | 100 | 12.0~35.0 | 1.52 |

| HBM3024 | 68 | 67 | 157 | 56 | 120 | 12.0~35.0 | 2.46 |

| HBM3624 | 68 | 67 | 157 | 56 | 120 | 15.0~50.0 | 2.63 |

| HBM3630 | 68 | 81 | 197 | 70 | 150 | 15.0~50.0 | 4.91 |

| HBM4230 | 88 | 81 | 197 | 70 | 150 | 18.0~60.0 | 5.14 |

| HBM4236 | 109 | 94 | 235 | 85 | 176 | 18.0~60.0 | 7.76 |

| HBM4836 | 109 | 94 | 235 | 85 | 176 | 30.0~80.0 | 8 |

| HBM4842 | 126 | 113 | 275 | 100 | 200 | 30.0~80.0 | 11.9 |

| HBM6448 | 133 | 134 | 309 | 110 | 226 | 30.0~80.0 | 18.7 |

*Please contact us separately regarding changing the L dimension of the bolt.

*The shape and specifications of the products listed in this catalog are subject to change without notice due to improvements.

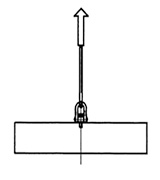

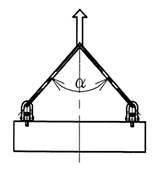

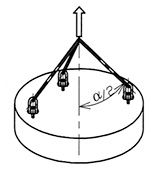

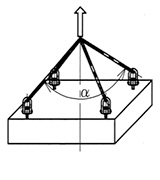

List of basic working loads by suspension method

|  |  |  | |||

| Number of pieces used | 1 | 2 | 3 or 4 | |||

| Hanging angle α | α=0° | α≦90° | 90°<α≦120° | α≦90° | 90°<α≦120° | |

| Mode coefficient M | 1 | 1.4 | 1 | 2.1 | 1.5 | |

| Product number | Working load | Unit: ton | ||||

| HBM2416 | 2.0 | 2.0 or less | 2.8 or less | 2.0 or less | 4.2 or less | 3.0 or less |

| HBM2420 | 2.8 | 2.8 or less | 3.9 or less | 2.8 or less | 5.9 or less | 4.2 or less |

| HBM3020 | 3.2 | 3.2 or less | 4.5 or less | 3.2 or less | 6.7 or less | 4.8 or less |

| HBM3024 | 4.2 | 4.2 or less | 5.9 or less | 4.2 or less | 8.8 or less | 6.3 or less |

| HBM3624 | 4.6 | 4.6 or less | 6.4 or less | 4.6 or less | 9.7 or less | 6.9 or less |

| HBM3630 | 6.5 | 6.5 or less | 9.1 or less | 6.5 or less | 13.7 or less | 9.7 or less |

| HBM4230 | 7.0 | 7.0 or less | 9.8 or less | 7.0 or less | 14.7 or less | 10.5 or less |

| HBM4236 | 8.5 | 8.5 or less | 11.9 or less | 8.5 or less | 17.9 or less | 12.7 or less |

| HBM4836 | 9.0 | 9.0 or less | 12.6 or less | 9.0 or less | 18.9 or less | 13.5 or less |

| HBM4842 | 12.0 | 12.0 or less | 16.8 or less | 12.0 or less | 25.2 or less | 18.0 or less |

| HBM6448 | 20.0 | 20.0 or less | 28.0 or less | 20.0 or less | 42.0 or less | 30.0 or less |

*In the case of a 4-wire suspension, the suspension angle is the angle of the opposing wires, etc. in the diagonal direction.

*Due to development and improvement, specifications may change without notice.

Round down to the second decimal place.

Related Products

-

UHT Corporation The Collets And Collet Nut For The Spindle No. 5 φ 2.5

-

Organo SD-HF/XP Electric Regeneration Pure Water Systems

-

Okudaya Giken LTX-U550-9L/ LTX-U800-10 Self-Propelled Lift Table Caddy

-

HANKOKU Siren Remote Control System

-

Tohnichi QLLS/CLLS/PQLLS/PCLLS/TiQLLS Pokayoke Torque Wrench

-

UHT Corporation DF7-06 #600 Diamond Stones