Japan

NCP NS-v Pilelock

Product Made In Japan

Manufacturer: NCP

Model: NS-v

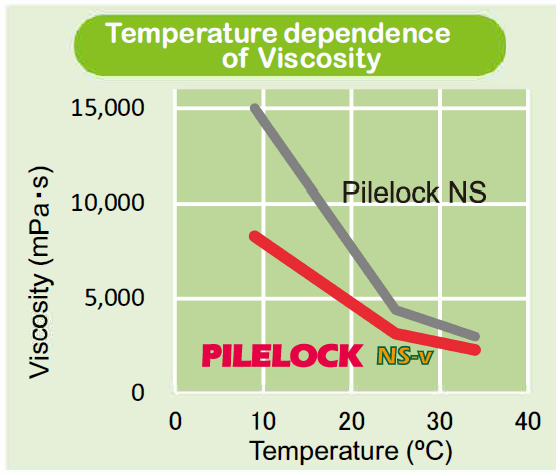

PILELOCK NS-v is a product with improved flow property and durability of PILELOCK NS widely used as a water-swellable interlock sealant for long time, and especially shows an excellent fluidity at lower temperature. Furthermore, PILELOCK NS-v is an eco-friendly and safe material since it contains no organic solvents as with PILELOCK NS and contributes to the improvement of working environment. When using steel sheet-piles as water sealing walls such as coverings, PILELOCK NS-v is recommended for applying to the interlock of sheet-piles before the execution of works since water sealing performance of sheet-piles are extremely improved by swollen PILELOCK NS-v in interlock.

- PILELOCK NS-v is a water-swellable interlock sealant and does not contain any volatiles like organic solvents in its composition.

- PILELOCK NS-v poured into slots of interlock forms water-swellable cross-linked rubbery coating films cured by surrounding moisture. PILELOCK NS-v swells up to six times by weight in 24 hours by contact with water. The swollen sealant inside the interlock is able to withstand water pressure at a depth of 50 meters.

ADVANTAGES

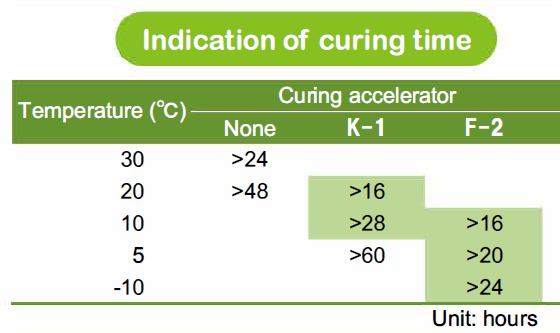

1) PILELOCK NS-v is one-pack type special urethane polymers in composition. It is possible to shorten curing time by adding a curing accelerator.

2) PILELOCK NS-v improves workability and safety at work because it does not release any odors or vapors.

3) Sheet-piles coated with cured PILELOCK NS-v are able to be driven and extracted as usual. The extracted water from swollen PILELOCK NS-v meets the groundwater standard of the Soil Contamination Countermeasures Act in Japan.

4) PILELOCK NS-v does not affect surrounding aquatic environments.

5) Easy to remove residue of PILELOCK NS-v from extracted sheet-piles in case of temporary works.

6) PILELOCK NS-v improves an efficiency and workability during coating especially in winter since its flow property and curability are very good at lower temperature.

HOW TO USE

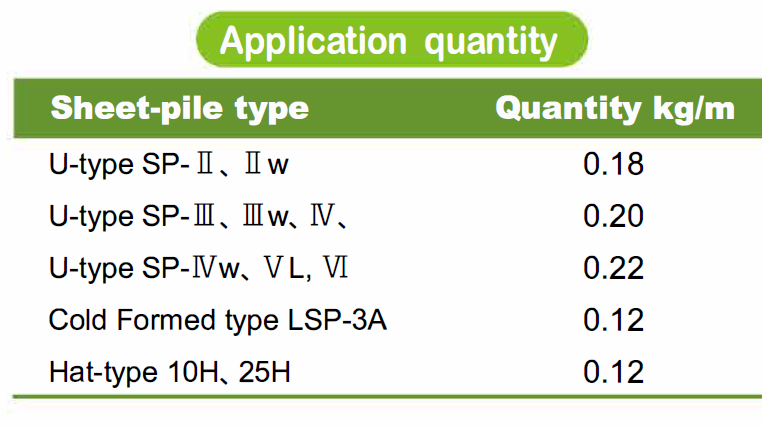

1) Stack sheet-piles using spacer e.g. square timber for a coating work.

2) Remove rust, mud, oil or water from interlock by scrapers, clothes or high-pressure air.

3) Cover both ends of interlock slots with clay or packing tape as a bank.

4) Pour PILELOCK NS-v to interlock by using oil jugs. Cover coated sheet-piles by plastic films or tarpaulins in case rain is expected.

5) Drive sheet-piles after confirming the completion of curing. 16 hours curing is required at 20 °C and 60%humidity. Curing rate becomes slower at lower temperatures or humidity.

6) Start digging or draining water from the next day of driving sheet-piles.

PRECAUTIONS

1) Use up all content in opened tins within the same day.

2) More curing time may be required at lower temperature.

3) Keep away from spark, naked flame and high temperature. Use it in well ventilated areas.

4) Keep containers tightly closed and store in well ventilated areas at below 40 °C.

5) Do not handle until all safety precautions or SDS have been read and understood.

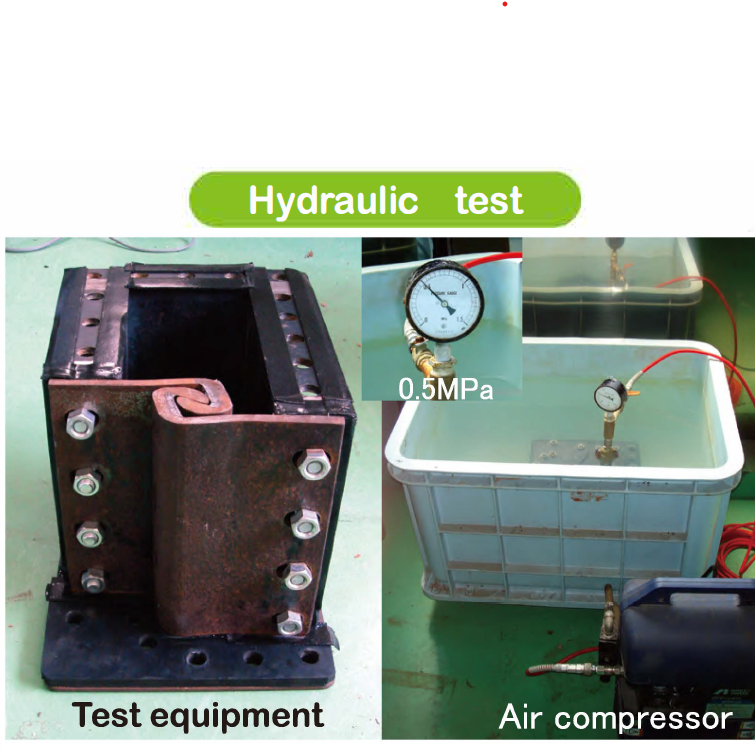

HYDRAUTIC TEST

Excellent sealing performance has been confirmed by using actual sheet-pile interlock.

1) Specimen under test: U-type SP-IV interlock

2) Application quantity: 0.2 kg/m/both-section

3) Condition: After soaking 48 hours in 3 wt% NaCl solution

4) Result: No leakage at 0.5 MPa

PACKAGING

PILELOCK NS-v : 16 kg oil tin Curing accelerator [mixed with 16 kg of NS-v]

K-1 [10 °C or more] : 0.5 kg oil tin F-2 [5 ~ 10 °C] : 0.5 kg oil tin