Japan, NIPPON DAIYA VALUE Co.

NDV Fixed ball type Ball Valves

Made in Japan

Manufacturer: NIPPON DAIYA VALUE Co., Ltd. (NDV)

NDV provides various types of ball valves suitable for a wild range of fields.

It is possible to select from a wide range of lineups such as multi-way valves and V-port valves to suit your application, in addition to the standard fire-safe type.

We also apply requests for special purpose valves used under high pressure and those for shield machine and nuclear power plants.

Fig. 1

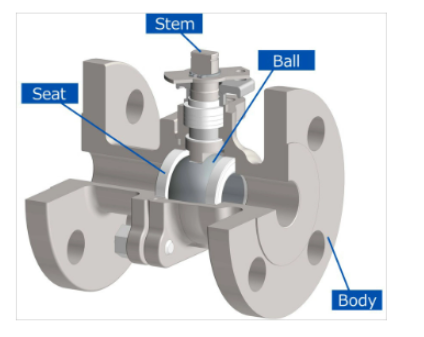

Basic structure and sealing principle of ball valves

Valves in which a ball rotates on a valve stem as a shaft to control the fluid.

As shown in Fig. 1, the flow path has the same shape as the piping, and there are few elements that give resistance to the fluid, so the structure has extremely low pressure loss when fully opened.

Features

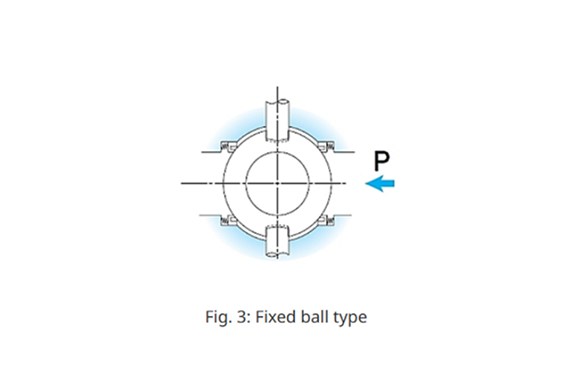

The fixed ball type has a structure in which the upper and lower portion of the ball are supported and fixed by the stem and trunnion as shown in Fig. 3. With this structure, the fluid is closed using the spring force at the back of the seat and the pressure on the primary side applied to the back of the seat when fully closed. Therefore, the seal is on the primary side, and it is characterized by less fluctuation of operating torque against fluctuation of flow pressure. It is mainly used for high pressure (JIS30K, CL600 or higher) and large bore size (DN250 or higher).

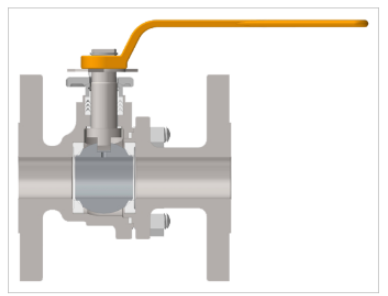

①Easy operation of fully open and closed

Fully open Fully closed

Opening and closing operations can be performed quickly by turning the stem 90 degrees.

In addition, the open/close state of the valve is clearly indicated by the position of the lever handle, so it has excellent visibility.

②Excellent sealing

PTFE and other plastic materials are used for the valve seat, which makes it easier to stop the fluid with excellent sealing performance.

③Extremely low pressure loss

Since its flow path has the same shape as the piping and there are few elements that give resistance to the fluid, the structure has an extremely low pressure loss when fully opened.

④Compatible with high-temperature and high-pressure fluids

A rich lineup of seat materials is available, and it is possible to apply with high-temperature and high-pressure fluids by selection.

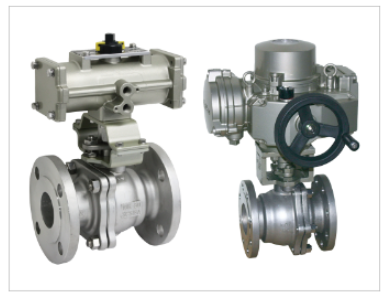

⑤Easy to automize

Our ball valves can be equipped with various types of actuators by simply attaching a yoke and coupling.

Related Products

-

KAMOI KAKOSHI No.501 W Waterproof Acrylic Double-sided Tape

-

Vessel No.CD-602 Conductive Vinyl Floor Sheet CD-leum

-

U_RD APT-3R (200V:1V) Power measurement equipment

-

UHT Corporation DZ-DESK Series Automatic Drilling Machine

-

Eisen PL Series Plain Gauge

-

Kimoto Couplings & Bodies Slope and furnace spraying construction materials