Japan, NIPPON DAIYA VALUE Co.

NDV Structure and features of diaphragm valves

Made in Japan

Manufacturer: NIPPON DAIYA VALUE Co., Ltd.

Model: Structure and features of diaphragm valves

NDV’s representative product, the diaphragm valves, are superior in “air-tightness,” “maintenance,” and “corrosion and chemical resistance.”

Since it can be configured by selecting from a wide range of materials according to fluid and usage conditions, it is applicable to a wide range of fields and has excellent cost performance.

Based on our extensive experience and achievements cultivated over our long history, we provide high-quality, high-performance and reliable products.

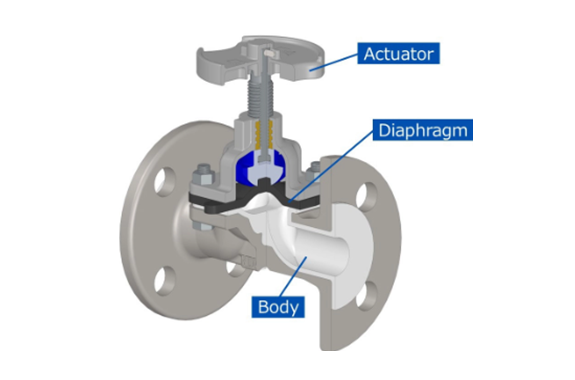

Basic structure and mechanism of diaphragm valves

- Diaphragm valves are generally refer to valves with a structure that opens and closes the flow path with a flexible diaphragm such as rubber.

- As shown in the figure below, the basic structure of the valve consists of three units: the actuator, the diaphragm, and the body. The fluid is controlled by pressing or separating the diaphragm against the seal on the inner surface of the body.

- Valve types are divided into two types: Weir types (400 type) and Straight types (500 type). The basic structures are the same.

Features

①Excellent airtightness

- Because the actuator is completely isolated from the flow path by the diaphragm, there is no leakage to the outside or contamination of the fluid from the outside air.

- Our diaphragms are subjected to various tests under severe conditions to confirm their durability and safety. It has high sealing reliability against external leakage and/or valve seat leakage and has been highly evaluated by users in a wide range of industries for its stable quality and performance.

②Excellent cleanability

- The fluid passage section is streamlined and has no pocket sections, which minimizes liquid pools and provides self-purification.

③Good maintainability

- This is a simple structure of three parts: the actuator, the diaphragm, and the body. Easy to disassembly and assembly.

- Due to top entry structure, the diaphragm can be replaced only by removing the bolts and nuts of the body with piping.

- Due to interchangeability of each parts, it is also easy to change manual valve to be automated valve.

④Excellent corrosion and chemical resistance

- The simple body shape, suitable for lining processing.

- The combination of various lining of bodies such as rubber and fluorocarbon resin and abundant diaphragm materials enables the valve to be manufactured to meet a wide range of fluid conditions. It also offers superior cost performance compared to special alloy-based materials.

⑤Environmentally friendly

- Since the structure is simple, the number of parts is less than that of other valve types, and there is no waste in consumables.

- Striving to reduce environmental impact by using lead-free chloroprene diaphragms and environmentally friendly paints, and by improving durability and reducing air consumption of actuator.

Related Products

-

SENSEZ PXV.PXI Compact Pressure Sensors

-

TONE WSW116R Wide Top Chest

-

Nagasaki Jack NWD-501G/501GP/501GR/501GRP Wide type

-

Vessel No.MX5P Double-ended MAGNUM bit (5 piece set)

-

Watanabe WRBI-DIO8V Digital input/output module – Remote I/O

-

SENSEZ Level Control YJ Water Level Control and Monitoring Devices