Japan, Nikkin Flux

Nikkin Flux Carbon, ALPUR SS, ALPUR3, ALPUR EG Degassing Mixer

Made in Japan

Manufacturer: Nikkin Flux

Model:Degassing Mixer: Carbon, ALPUR SS, ALPUR3, ALPUR EG

Features of Nikkin’s Degassing Mixer

High degassing effect

A wide variety of mixers are

Anti-oxidation treatment (impregnation treatment) on the surface of the mixer

Made of high quality domestic carbon

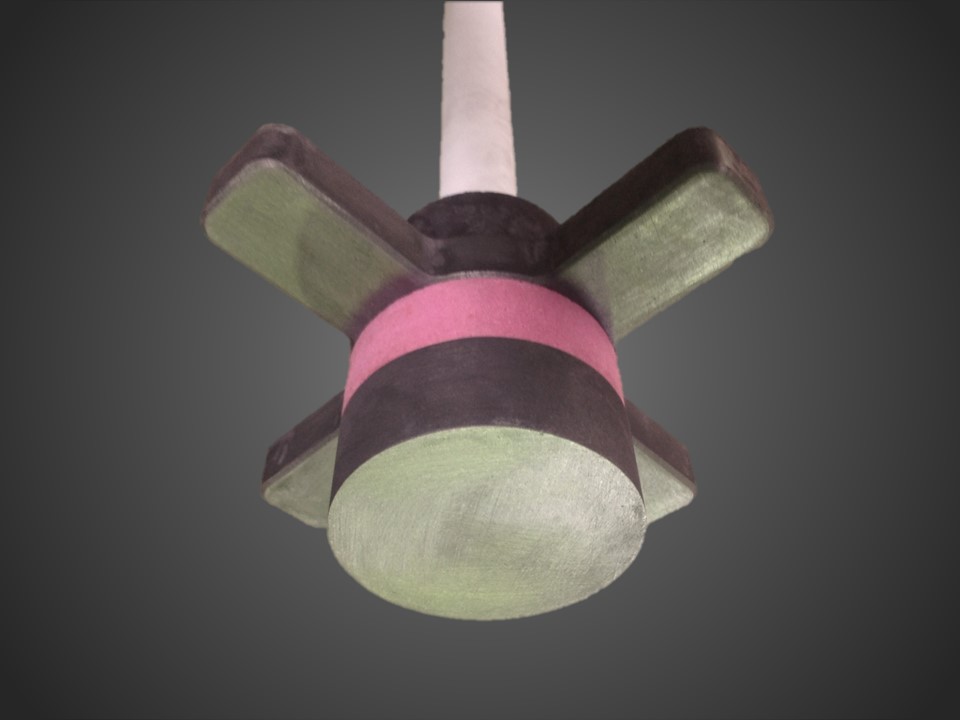

Carbon Mixer

Carbon mixer with bubble crashing method. We supply customized carbon mixer based upon your furnace and frange drawing or current create drawing from existing mixer. Application: inline degassing equipment.

Max size: Shaft: Carbon (OD80 x L1000mm) Impeller : Carbon (OD240mm)

Production leadtime: 1-2weeks

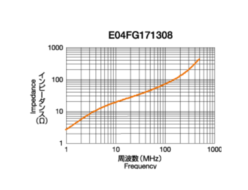

ALPUR SS Mixer

Ceramic mixer with bubble crashing method. Application: inline degassing equipment, furnance

Insert Gas: Ar or N2 30L/min (0.3MPa)

Frange: EG Type (PCD110 6-OD11)

Material: Shaft: SIALON (OD55 x L1200mm) Impeller : Super SIALON (OD240 x L40mm, 8 Impellers)

ALPUR3 Mixer

ALPUR EG Mixer

Material: /b> Adapter, Impeller, Screw Nut: Carbon Shaft: SIALON Porous Ring: Hi-Alumina

Other items of Nikkin Flux

Request the quotation for Nikkin Flux