Japan, Nippon Seimitsu

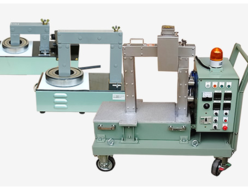

Nippon Seimitsu CP Series Multi-stage Turbo Blower

Product Made in Japan

Manufacturer: Nippon Seimitsu Co., Ltd.

Model: CP Series

Blower

A device that generates a large volume of high-pressure air by rotating an impeller at high speed, designed based on fluid theory

A blower designed based on fluid theory

- As a power source for dust collection and cleaning equipment

- Used in various situations where suction and discharge are required

- The basic design eliminates the surging area, allowing for free operation without having to worry about the operating area.

- Air filters, exhaust silencers, and other options available

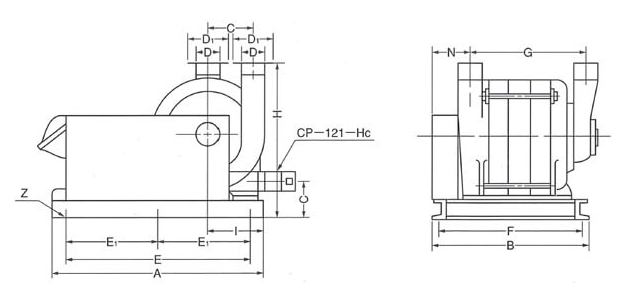

Multi-stage Turbo Blower (1)

Our standard multi-stage turbo blower serves as a suction source or discharge source for various devices.

It offers a wide range of performance, from high pressure and low air volume to medium pressure and medium air volume, and is characterized by its ease of use with no surging range.

Overview

Dimensions

| Classification | Specifications | Performance (point of use) | Electric motor | Belt type – Book | External dimensions (mm) | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Air volume m3/min | Static pressure kPa | Rotation speed: 50/60 min-1 | Power phase -V | Output power (kW) | Number of poles | A | B | C | D | E/E1 | F | G | H | I | N | Z | D1 | Flanges | |||

| Belt transmission pressure type | CP3-122-H4 | 2 | 12.74 | 5800 | 3-200 | 1.5 | 2 | A-2 | 570 | 440 | 127 | 80 | 450 | 410 | 286 | 390 | 140 | 119 | 4-⌀14 | |||

| CP3-122-H3 | 5.6 | 5.9 | 4655 | 3-200 | 1.5 | 2 | A-2 | 630 | 360 | 150 | 102 | 500 | 330 | 209 | 515 | 190 | 146 | 4-⌀14 | ||||

| CP3-123-H3 | 6 | 8.8 | 4550 | 3-200 | 2.2 | 2 | A-2 | 700 | 530 | 150 | 102 | 580 | 490 | 321 | 520 | 190 | 167 | 4-⌀14 | ||||

| CP3-125-H3 | 6 | 13.7 | 5350 | 3-200 | 3.7 | 2 | A-3 | 700 | 530 | 150 | 102 | 580 | 490 | 321 | 520 | 190 | 167 | 4-⌀14 | ||||

| CP3-5500A-H | 6 | 20.58 | 5650 | 3-200 | 5.5 | 2 | A-4 | 760 | 556 | 150 | 102 | 600 | 520 | 433 | 560 | 200 | 133 | 4-⌀14 | ||||

| CP3-1210-H3 | 20 | 7.84 | 3800 | 3-200 | 7.5 | 4 | A-4 | 940 | 620 | 180 | 165 | 320 | 584 | 534 | 710 | 220 | 132 | 6-⌀14 | ||||

| CP3-1210-H4 | 6 | 22.54 | 5200 | 3-200 | 7.5 | 2 | A-5 | 760 | 686 | 150 | 102 | 600 | 650 | 545 | 585 | 200 | 145 | 4-⌀14 | ||||

| CP3-11KA-H | Ten | 23.52 | 4000 | 3-200 | 11 | 4 | V-3 | 1020 | 680 | 237 | 106 | 400 | 620 | 425 | 795 | 295 | 185 | 6-⌀18 | 185 | ○ | ||

| CP3-1215-H3 | 20 | 12.74 | 4100 | 3-200 | 11 | 2 | V-6 | 960 | 750 | 180 | 165 | 350 | 710 | 636 | 735 | 240 | 155 | 6-⌀18 | ||||

| CP3-15KA-H | 12 | 27.44 | 4000 | 3-200 | 15 | 4 | V-3 | 1020 | 790 | 237 | 106 | 400 | 730 | 535 | 795 | 295 | 185 | 6-⌀18 | 185 | ○ | ||

| CP3-1230-H | 15 | 29.4 | 3500 | 3-200 | 22 | 4 | V-4 | 1300 | 970 | 272 | 120 | 1000 | 900 | 650 | 950 | 375 | 197 | 4-⌀24 | 235 | ○ | ||

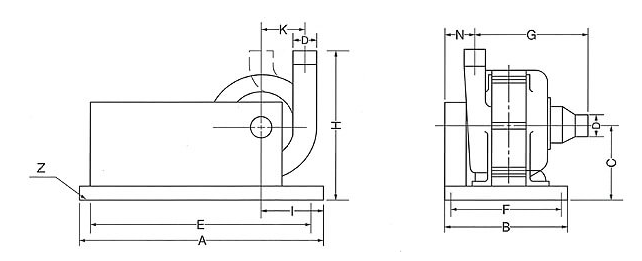

Multi-stage turbo blower (2)

This type of turbo blower has the suction port located at the front of the equipment.

Overview

Dimensions

| Classification | Specifications | Performance (point of use) | Electric motor | Belt type – Book | External dimensions (mm) | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Air volume m3/min | Static pressure kPa | Rotation speed: 50/60 min-1 | Power phase -V | Output power (kW) | Number of poles | A | B | C | D | D1 | E | F | G | H | I | K | N | Z | |||

| Belt transmission pressure type | CP3-121-H7 | 2.5 | 5.6 | 7300 | 3-200 | 0.75 | 2 | A-1 | 550 | 330 | 165 | 68 | 63.5 | 450 | 300 | 127 | 335 | 135 | 0 | 201 | 4-⌀9 | |

| CP3-123-H4 | 3.5 | 14.7 | 7800 | 3-200 | 2.2 | 2 | Flat A-2 | 600 | 400 | 195 | 80 | 76 | 500 | 370 | 363 | 385 | 140 | 127 | 129 | 4-⌀10 | ||

| CP3-3700A-H | 3 | 19.6 | 7750 | 3-200 | 3.7 | 2 | Flat A-3 | 650 | 460 | 245 | 80 | 76 | 500 | 430 | 455 | 415 | 125 | 127 | 102 | 4-⌀14 | ||

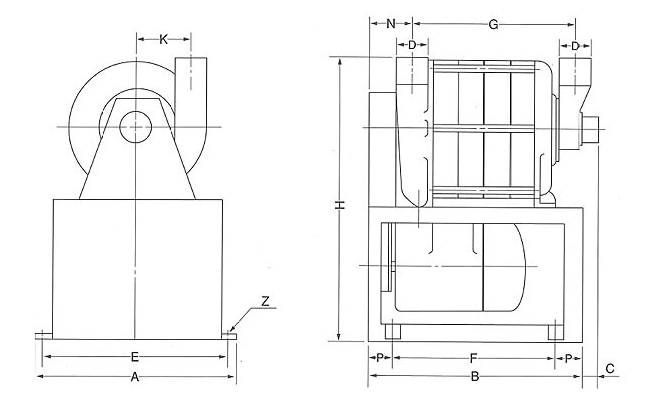

Multi-stage turbo blower (3)

This is a space-saving (vertical) turbo blower.

Overview

Dimensions

| Classification | Specifications | Performance (point of use) | Electric motor | Belt type – Book | External dimensions (mm) | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Air volume m3/min | Static pressure kPa | Rotation speed: 50/60 min-1 | Power supply phase -V | Output power (kW) | Number of poles | A | B | C | D | E | F | G | H | K | N | P | Z | |||

| Belt transmission pressure type | CPK3-123-V1 | 2 | 18.1 | 7100 | 3-200 | 2.2 | 2 | A-2 | 480 | 460 | 30 | 80 | 450 | 300 | 286 | 710 | 127 | 135 | 80 | 4-⌀15 | |

| CPK3-125-V1 | 3.4 | 19.6 | 7450 | 3-200 | 3.7 | 2 | A-3 | 480 | 570 | 30 | 80 | 450 | 370 | 394 | 710 | 127 | 135 | 100 | 4-⌀15 | ||

| CPK3-1275-V1 | 6 | 19.6 | 5400 | 3-200 | 5.5 | 2 | A-4 | 540 | 620 | 30 | 102 | 510 | 510 | 433 | 930 | 150 | 142 | 55 | 4-⌀15 | ||

Related Products

-

Nippon Chemical Screw PA66/BU(Nominal diameter) PA66 (66 nylon)/Bush

-

Kanetec KETN-3060A Powerful Waveform Electromagnetic Chuck

-

SANKO ELECTRONIC LABORATORY TY-20Z Needle And Iron Piece Detector Metal Detector

-

TONE BLB-S Short Neck Long Ball Point Hex Key Wrench L-Type

-

Fukudaco Bearing Heater

-

KGK BMN Wideband Vertical Transducers