Bolt & Nut, High Tension Bolt, Japan, Nippon Steel Bolten

NIPPON STEEL BOLTEN – SHTB Torque Type Super High Strength Bolt

Made in Japan

Manufacturer: Nippon Sumikin Bolten

Model: SHTB

Features

- SHTB is an epoch-making bolt that overcomes delayed fracture by adopting bolt shape and new thread shape which can mitigate stress concentration, development of material excellent in delayed fracture resistance, and about 1.5 of conventional bolt (F10T) We realized ultrahigh strength as doubled.

- I obtained the certification of the Minister of Land, Infrastructure, Transport and Tourism (certification number: MBLT – 0113).

- By adopting SHTB, many merits such as compact bolt joint, reduced bolt tightening cost, shortened construction period, etc. are obtained.

- Construction has the same efficient tightening workability as the conventional Torsha type high-strength bolt.

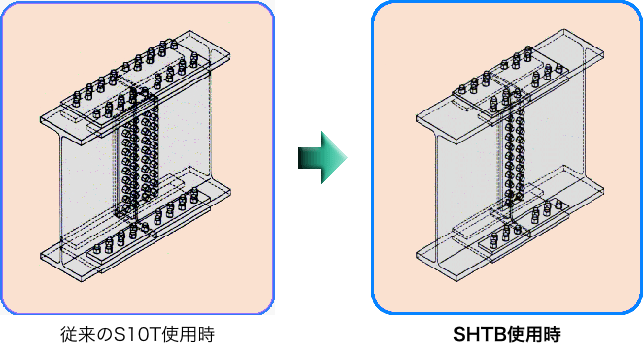

Conceptual diagram of fitting compactification

Size Chart

Weight of bolt (unit: g)

| Neck Length | Bolt type | |||

|---|---|---|---|---|

| SHTB 16 | SHTB 20 | SHTB 22 | SHTB 24 | |

| 50 | 222 | |||

| 55 | 230 | 378 | ||

| 60 | 238 | 391 | 526 | |

| 65 | 246 | 404 | 541 | 714 |

| 70 | 254 | 417 | 556 | 732 |

| 75 | 262 | 430 | 571 | 750 |

| 80 | 270 | 443 | 586 | 768 |

| 85 | 278 | 456 | 601 | 786 |

| 90 | 286 | 469 | 616 | 804 |

| 95 | 294 | 482 | 631 | 822 |

| 100 | 302 | 495 | 646 | 840 |

| 105 | 310 | 508 | 661 | 858 |

| 110 | 521 | 676 | 876 | |

| 115 | 534 | 691 | 894 | |

| 120 | 547 | 706 | 912 | |

| 125 | 560 | 721 | 930 | |

| 130 | 573 | 736 | 948 | |

| 135 | 751 | 966 | ||

| 140 | 766 | 984 | ||

| 145 | 781 | 1002 | ||

| 150 | 1020 | |||

| 155 | 1038 | |||

| 160 | 1056 | |||

Bolt length

Please choose the bolt’s neck length by adding the following length to the tightening length (the total thickness of the steel to be tightened).

| Bolt type | Add length (mm) | (Note) It is 5 mm longer than the “added length” of the conventional TC bolt. |

|---|---|---|

| SHTB 16 | 30 | |

| SHTB 20 | 35 | |

| SHTB 22 | 40 | |

| SHTB 24 | 45 |

standard

Mechanical properties of bolt

| standard | Proof stress (N / mm²) | Tensile strength (N / mm²) | Elongation (%) | Aperture (%) | Hardness (HRC) |

|---|---|---|---|---|---|

| SHTB | 1,260 or more | 1,400 to 1,490 | 14 or more | 40 or more | 39 – 47 |

Design proof

| Bolt type | Long-term tolerable capacity (kN) | Short term permissible proof stress (kN) | ||||

|---|---|---|---|---|---|---|

| 1-sided shear | Two-sided shear | Tension | 1-sided shear | Two-sided shear | Tension | |

| SHTB 16 | 46 | 92 | 92 | 69 | 138 | 139 |

| SHTB 20 | 72 | 143 | 144 | 107 | 215 | 217 |

| SHTB 22 | 87 | 173 | 175 | 130 | 260 | 262 |

| SHTB 24 | 103 | 206 | 208 | 155 | 309 | 312 |

| Bolt type | Maximum yield strength (kN) | ||

|---|---|---|---|

| 1-sided shear | Two-sided shear | Tension | |

| SHTB 16 | 169 | 338 | 230 |

| SHTB 20 | 264 | 528 | 358 |

| SHTB 22 | 319 | 639 | 442 |

| SHTB 24 | 380 | 760 | 517 |

Design bolt tension

| Bolt type | Effective cross section (mm²) | Reference tension | Tensile long-term permissible stress | Design bolt tension (kN) | Standard bolt tension (kN) |

|---|---|---|---|---|---|

| SHTB 16 | 164 | 760 (N / mm²) | 460 (N / mm²) | 155 | 171 |

| SHTB 20 | 256 | 242 | 266 | ||

| SHTB 22 | 316 | 299 | 329 | ||

| SHTB 24 | 369 | 349 | 384 |

Here, the reference value of material strength (specified proof stress) = 1260 (N / mm²).

Remarks: Design bolt tension = effective cross-sectional area × specified proof stress × 75%

standard bolt tension = 10% increase of design value (same concept as S10T)

Introduction tension

| Bolt type | Introduced tension average value at normal temperature (kN) | Introduced tension average value (kN) other than room temperature |

|---|---|---|

| SHTB 16 | 161 to 193 | 155 to 203 |

| SHTB 20 | 252 to 302 | 242 to 317 |

| SHTB 22 | 311 to 373 | 299-391 |

| SHTB 24 | 363 to 435 | 349 to 457 |

Standard sign (Certification number of the Minister of Land, Infrastructure, Transport and Tourism)

| standard | Remarks | Certification number |

|---|---|---|

| SHTB | Minister of Land, Infrastructure, Transport and Tourism General Certification Standard | MBLT-0113 |

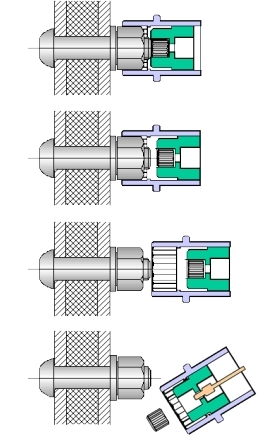

Construction

It has the same efficient tightening workability as the conventional Torsha type high-strength bolt.

- Fully insert the inner sleeve into the bolt grip, then gently press the clamping machine and snap the outer sleeve onto the nut.

- Switch on the clamping machine.

The outer sleeve is rotated and tightened, and when the specified torque is reached the rupture groove is cut. - When the fracture groove breaks, switch off, simultaneously pull the tightening machine toward you and remove the outer sleeve.

- Pull the tip lever and pull out the pin tail of the inner sleeve.

【Precautions for use】

- Please use SHTB in indoor environment. Also, please do not use it indoors under the corrosive environment such as hot spring facilities, hot water pool etc. (For delayed breakdown prevention) If you are unsure about the use environment, please consult us.

- 12 G SHTB (12 G hot dip galvanized high strength hexagon bolt) is available for outdoor use, so please consult us separately.

- Since the introduction tension of SHTB is higher than ordinary high tension bolt, please use the corresponding tightening machine.

- When tightening, please check the mark of the bolt head.

SHTB compliant tightening machine list

| Primary tightening model list | |||||

|---|---|---|---|---|---|

| Bolt type | Shear runner type | Shear wrench type | |||

| SR-31 | SR-51 | KS-2024-1 | KS-4001 B | 6922K | |

| SR-32 | SR-52 | KS-2024-2 | KS-4002B | ||

| SHTB 16 | ○ | ○ | ○ | ||

| SHTB 20 | ○ | ○ | ○ | ||

| SHTB 22 | ○ | ○ | ○ | ||

| SHTB 24 | ○ | ○ | |||

| Torque range | 150 to 300 N · m | 300 to 500 N · m | 160 to 310 N · m | 300 to 500 N · m | 118 to 225 N · m |

| Machine type list for final tightening | ||||||

|---|---|---|---|---|---|---|

| Bolt type | M-201 RAT | GM-201AT | GM-221 AT | GH-241AT | V301T | 6924N |

| M-202 RAT | GM-202AT | GM-222AT | GH-242AT | V302T | ||

| SHTB 16 | ○ | ○ | ○ | |||

| SHTB 20 | ○ | ○ | ||||

| SHTB 22 | ○ | ○ | ○ | |||

| SHTB 24 | ○ | ○ | ||||