Nissan Tanaka

NISSAN TANAKA 115Z/515Z/151/15405E Blowpipe

Manufacturer: Nissan Tanaka

Model: 115Z/515Z/151/15405E

Gouging Blowpipe

Features

Ideal for processing such as back-gouging of weld joints, removal of defects, and trimming of corner materials.

Available in two types: for acetylene gas (model: 115Z) and for LPG (model: 515Z).

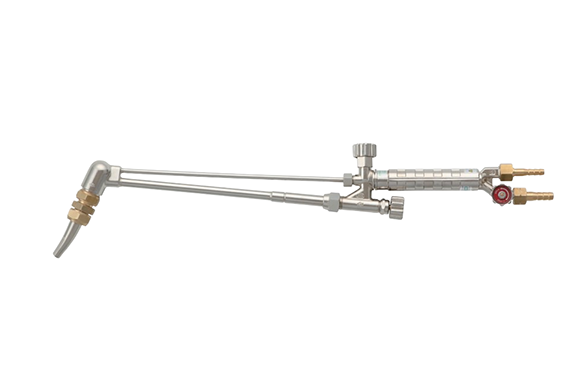

Gouging Blowpipe Z

For processing with approximate dimensions of width between 5 to 17mm and depth between 3 to 12mm (dimensions of the groove).

Gouging (Groove Cutting) is a method used primarily for the back-gouging of welded joints. It involves heating the required area with a preheating flame of oxygen and acetylene (or propane) and then blowing away the formed iron oxide using the heat generated by the oxidation reaction.

Scarfing Blowpipe

Features

We offer two types that are ideal for scarfing operations (C65 and 1000E).

C65 can be used with acetylene or LPG by changing the nozzle.

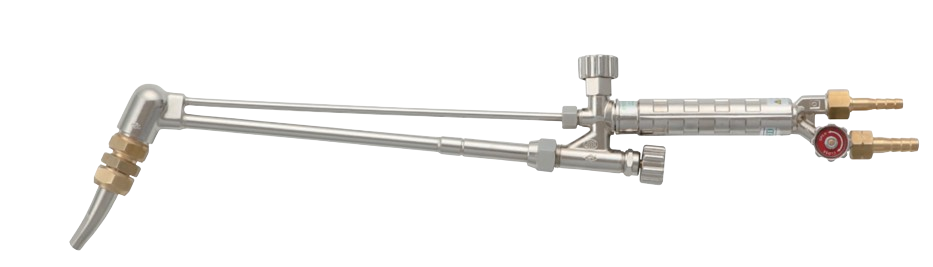

Mighty-C65 scarfing blowpipe

For processing scarf dimensions with a groove width of 23 to 40mm and groove depth of 1 to 2mm. Its primary application is for removing burrs at the tundish, among other uses

Scarfing (or metal scarfing) is a method used to remove defects and impurities that have occurred on the surface of steel pieces in order to maintain high-quality steel. This is done by heating the required area with a preheating flame, such as oxygen and acetylene (or propane), and then blowing away the iron oxide formed by the oxidation reaction with oxygen. Scarfing is a process used to remove defects and impurities from the surface of steel.

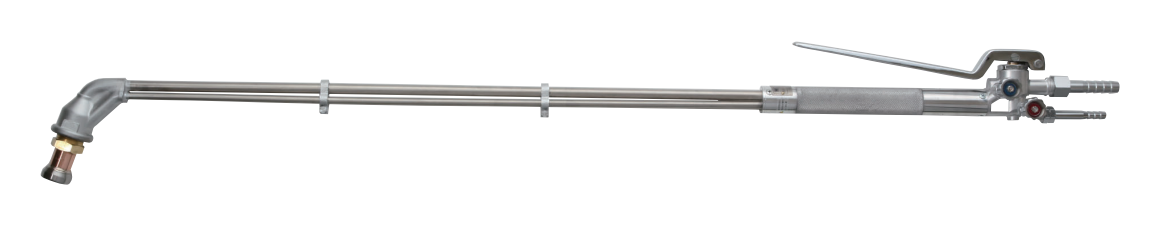

Mighty 1000E scarfing blowpipe

For processing scarfing width between 80-110mm and scarfing depth of 2-3mm (shallow scarfing) or 4-5mm (deep scarfing). Its primary application is for removing blemishes on slabs and similar uses

For processing scarfing width between 80-110mm and scarfing depth of 2-3mm (shallow scarfing) or 4-5mm (deep scarfing). Its primary application is for removing blemishes on slabs and similar uses

Dedicated Nozzle Capacity Chart

Gouging blowpipe

| Product name | Fuel Gas Used | Model | Nozzle Type | Approximate Groove Dimensions(mm) | Gas Pressure(MPa) | Gas Consumption (m³/h) | Total Length (mm) |

Weight (g) |

Connection Type | |||||

| Series Name | Number | Width | Depth | Oxygen | Fuel Gas | Cutting Oxygen | Preheating Oxygen | Fuel Gas | ||||||

| Gouging Blowpipe Z | Acetylene | 115Z | 1520 | 1 | 5〜9 | 3 — 6 | 0.3 – 0.5 | 0.01-0.05 | 2.4 – 4.4 | 0.38 – 0.93 | 0.35 – 0.85 | 522 | 800 | Oxygen JIS 2nd Grade Hose Fuel Gas JIS 3rd Grade Hose |

| 2 | 7〜10 | 3 — 6 | 0.3 – 0.5 | 2.8-5.1 | 0.46-1.21 | 0.42-1.10 | ||||||||

| 3 | 9〜13 | 5-10 | 0.4 – 0.7 | 3.0 – 5.5 | 0.49-1.21 | 0.45-1.10 | ||||||||

| 4 | 9〜13 | 5-10 | 0.4 – 0.7 | 3.2 – 5.7 | 0.51-1.32 | 0.47-1.20 | ||||||||

| 5 | 10-15 | 5-12 | 0.4 – 0.7 | 3.2 – 6.0 | 0.51-1.32 | 0.47-1.20 | ||||||||

| 6 | 10-15 | 5-12 | 0.4 – 0.7 | 3.4 〜6.5 | 0.55-1.43 | 0.50-1.30 | ||||||||

| 7 | 11-17 | 5-12 | 0.5 – 0.8 | 0.02 – 0.06 | 3.5 – 7.2 | 0.58-1.54 | 0.53-1.4 | |||||||

| Propane | 515Z | 1550 | 1 | 5-9 | 3 — 6 | 0.3 – 0.5 | 0.01-0.05 | 2.4 – 4.4 | 3.2 | 0.85 | ||||

| 2 | 7-10 | 3 — 6 | 0.3 – 0.5 | 2.8-5.1 | 3.2 | 0.85 | ||||||||

| 3 | 9-13 | 5 — 10 | 0.4 – 0.7 | 3.0 – 5.5 | 5.7 | 1.50 | ||||||||

| 4 | 9-13 | 5 — 10 | 0.4 – 0.7 | 3.2 – 5.7 | 5.7 | 1.50 | ||||||||

| 5 | 10-15 | 5-12 | 0.4 – 0.7 | 3.2 – 6.0 | 6.0 | 1.6 | ||||||||

| 6 | 10-15 | 5-12 | 0.4 – 0.7 | 3.4 – 6.5 | 6.0 | 1.6 | ||||||||

| 7 | 11-17 | 5-12 | 0.5 – 0.8 | 0.02 – 0.06 | 3.5 – 7.2 | 6.8 | 1.8 | |||||||

※We also have A-cutting nozzles, 1520L and 1550L, available for the gouging nozzle series that you already have.

Scarfing blowpipe

| Product name | Fuel Gas Used | Model | Nozzle Type | Approximate Groove Dimensions (mm) | Gas Pressure(MPa) | Gas Consumption (m³/h) | Total Length (mm) | Weight (g) | Connection Type | |||||

| Series Name | Number | Width | Depth | Oxygen | Fuel Gas | Cutting Oxygen | Preheating Oxygen | Fuel Gas | ||||||

| Mighty-C65 scarfing blowpipe | Acetylene | 151 | 5140 | 6 | 23 〜25 | 1〜2 | 0.6 〜0.8 | 0.06 | 16 〜24 | 0.93 | 0.84 | 1,304 | 1,980 | Oxygen JIS 2nd Grade Hose Fuel Gas JIS 3rd Grade Hose |

| 8 | 25 〜28 | 0.6 〜0.8 | 0.06 | 25 〜38 | 1.23 | 1.12 | ||||||||

| 10 | 30〜35 | 0.6 〜0.8 | 0.07 | 28 〜42 | 1.54 | 1.40 | ||||||||

| 12 | 32 〜37 | 0.7 〜0.9 | 0.07 | 30〜45 | 1.85 | 1.68 | ||||||||

| 14 | 35 〜40 | 0.8 〜1.0 | 0.08 | 36 〜54 | 2.16 | 1.96 | ||||||||

| Propane | 5150 | 6 | 14 〜17 | 0.6 〜0.8 | 0.06 | 10〜15 | 1.88 | 0.50 | ||||||

| 8 | 18 〜21 | 0.06 | 16 〜24 | 2.06 | 0.55 | |||||||||

| 10 | 23 〜25 | 0.07 | 23 〜34 | 2.25 | 0.60 | |||||||||

| 12 | 25 〜28 | 0.07 | 30〜45 | 3.19 | 0.85 | |||||||||

| 14 | 3〇〜35 | 0.08 | 33 〜50 | 3.75 | 1.00 | |||||||||

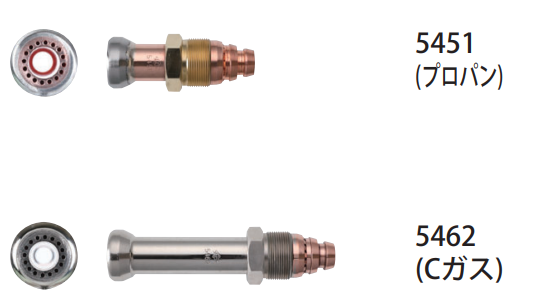

※We also have a 5462 nozzle available for C-gas. Please contact our sales department for more details.

| Product name | Fuel Gas Used | Model | Nozzle Type | Length (mm) | Weight (g) | Connection Type |

| Mighty 1000E Scarfing Blowpipe | Propane | 15405E | 5451 | 1,297 | 2,900 | 1/2-inch Oxygen Hose Fuel Gas JIS No. 3 Hose Nozzle |

| Division | Oxygen pressure | Fuel gas pressure | Width | Depth (mm) | Oxygen consumption (m³/h) | Fuel gas consumption (m³/h) |

| Shallow | 0.8 〜1.0 | 0.04 | 80〜110 | 2〜3 | 195〜210 | 1.4 |

| Deep | 4〜5 | 195〜210 | 1.4 |

Kouei is Distributor/Agent of Nissan Tanaka

Other items of Nissan Tanaka

Request the quotation for Nissan Tanaka

Related Products

-

NISSAN TANAKA 0MC Series Analytical Pressure Regulators

-

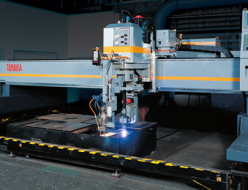

NISSAN TANAKA KT-790 NC Gas Cutting Machine

-

NISSAN TANAKA KT-790PMX Ⅱ Plasma Bevel Cutting Machine

-

NISSAN TANAKA [FP] Flame Planer

-

NISSAN TANAKA 114C, 514C Cutting Torch (C Type)

-

NISSAN TANAKA V-F22AR, AU-888 Pressure Regulator For Other Applications