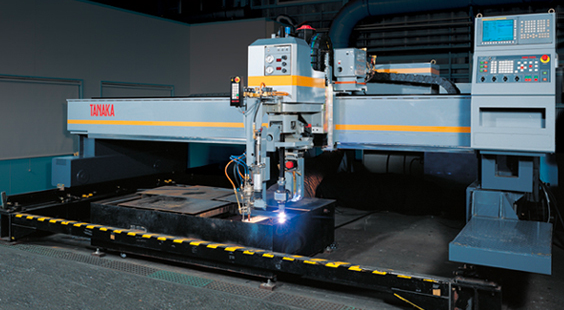

Cutting, Japan, Nissan Tanaka

NISSAN TANAKA KT-790PMX Ⅱ Plasma Bevel Cutting Machine

Manufacturer: Nissan Tanaka

Model: KT-790PMX Ⅱ

High-speed, Stable Cutting Performance!

Reduce cost with higher speeds!

The KT-790PMX Ⅱ is a plasma cutting machine that offers the ultimate in high-speed performance. In addition to the industry’s fastest traveling feed rates, it is capable of cutting speeds that are 1.3 to 2.0 times faster than conventional machines (depending on sheet metal thickness). It also provides high acceleration along the X and Y axes (3 times faster than conventional machines), as well as an ultra rapid traverse (50,000 mm/min). Together with a faster torch up-down speed (18,000 mm/min) and the incorpo- ration of the latest CNC system unit, the KT-790PMX Ⅱ dramatically shorten total cutting time.

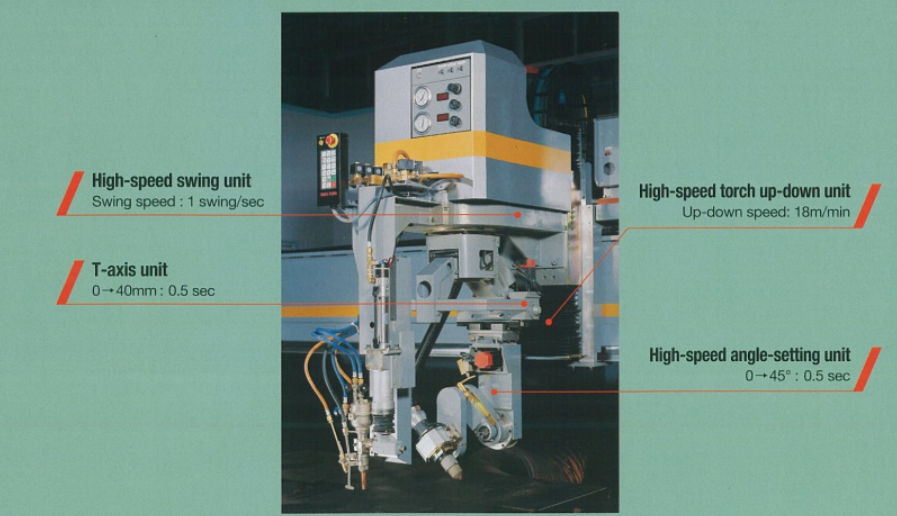

Automatic Bevel Cutting Unit

Bevel processing with a plasma cutting unit has initially become popular in the ship-building industry, and rapidly spread to other industries. In response to customer needs, Nissan Tanaka has continued to develop torch blocks for automatic bevel cutting. Recently, we have included two new types of bevel torch blocks to our lineup, to meet increasingly diverse bevel processing needs and demands for higher cutting quality.

Plasma Cutting Machine with High-speed Link Torch Block A high-speed angle setting unit and a high-speed torch rotation unit has been added to a conventional automated bevel torch block. A T-axis (horizontal shift) can be applied to both “S&T” and “S&D” command control.

Major Features

Speed, the greatest advantage of plasma cutting, has been further enhanced in the KT-790PMX Ⅱ. Nissan Tanaka has succeeded in achieving dramatically-high cutting speeds by reinforcing machine rigidity, increasing the accel- eration of the drive system, and employing the latest NC unit.

- High-current cutting allows 1.3 to 2.0 times faster cutting speeds compared to conventional machines depending on sheet metal thickness).

- Increased speeds along the X and Y axes (3 times faster acceleration compared to conventional machines), the adoption of an ultra rapid feed mode (50,000 mm/min), and a faster torch up-down speed (18,000 mm/min) ensure significant reduction in total cutting time.

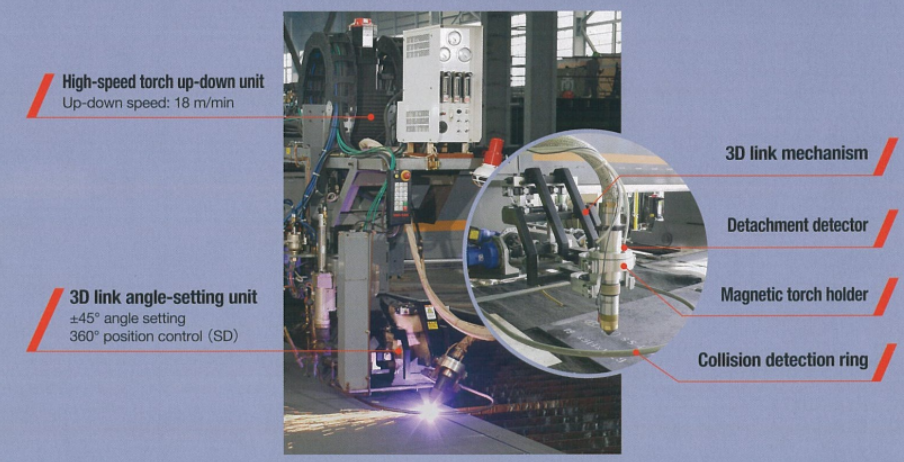

Plasma Cutting Machine with 3D Link Torch Block :The rotation of conventional machines has been eliminated, to produce a new type of automated bevel torch block that employs two drive units and a 3D link mechanism to control bevel position.

Main features

- Employs FANUC motors with the high-speed torch rotation and bevel angle setting Angle-setting speed: 90°/sec, rotation speed: max. 60 rpm The bevel unit is driven using axis control in the CNC unit

- Equipped with a T-axis to allow both “S&T” and “S&D” bevel control

- Compatible with conventional NC data

- Compatible with third-party NC data (with minor modification of programming data)

Main features

- Compact and lightweight bevel torch block without torch rotation mechanism

- Approx. 1.5 times faster bevel torch position-setting speed (compared to conventional company machines)

- Simple and speedy alignment adjustments (requires one-fourth the time required by conventional company machines)

- Employs a torch holder with a magnet attachment/detachment structure, to reduce torch damage and misalignment of the bevel unit that are often caused by the torch coming into contact with the sheet metal

- Easy-to-replace torch cable

- Bevel control by “S&D” command

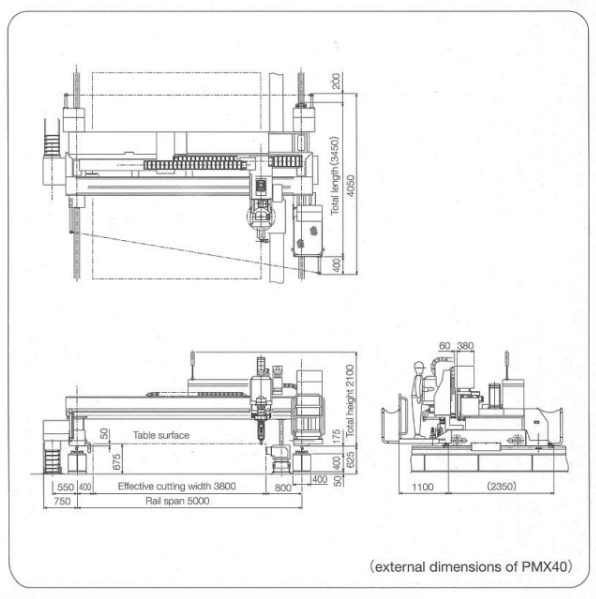

Specifications of the KT-790PMX Ⅱ

| Model | KT-790PMX Ⅱ | ||||||

|---|---|---|---|---|---|---|---|

| Effective cutting width [mm] | 2,800 | 3,300 | 3,800 | 4,300 | 4,800 | 5,300 | 5,800 |

| Rail span (mm) | 4,000 | 4,500 | 5,000 | 5,500 | 6,000 | 6,500 | 7,000 |

| Rail length (mm) | Standard: 9,600 *Rail length can be extendable as per 1,200 | ||||||

| Effective cutting length [mm] | Total Length -4,300 | ||||||

| Torch rotated system | 3D Link (TCL) | ||||||

| Option functions | Stainless Steel Cutting Function, Marking Device, Dust Collector, etc. | ||||||

| NC device | FANUC Series 31iMB | ||||||

| Driving system | Dual Side Rack & Pinion Drive | ||||||

| Torch head lifting speed (mm/min) | 20,000 | ||||||

| Torch head descending speed (mm/min) | 20,000 | ||||||

| Rail size | 50 kg/m | ||||||

Utility

Input power source

| Main unit | 30KVA |

|---|---|

| Plasma power source | 130KVA (with Pegasus 500) 70KVA (with HPR-260) |

| Cooling water circulation unit | 5KVA (with Pegasus 500) |

Fluides

| Pegasus 500 | Oxygen | 0.7MPa | 6 m³/h |

|---|---|---|---|

| Air | 0.7MPa | 55m³/h | |

| Water | – | 1 m³/h | |

| HPR-260 | Oxygen | 0.8 MPa | 6 m³/h |

| Air | 0.8 MPa | 55 m³/h |

※LPG gas is needed when using the optional Z-marker.

※Air volume may vary according to machine specifications.

Standard components

- Operator deck

- Vertical cutting torch block

- Arc tracing sensor + initial height sensor

- Access prevention sensor (phototube safety device)

- Revolving light (3 colors)

- Coordinate rotation function

- Scheduled operation function

- Fume purging fan

- Cutting status display

※Automatic operation time, piercing time and rotation, drawing displays, cutting conditions, etc. are displayed on the control panel LCD

Optional specifications

- Automatic bevel cutting unit (high-speed link or 3D link unit)

- Z-marker

- Electrode consumption detector

- Dust collector (stand-alone type)

- Stainless steel cutting function

-

Kouei is Distributor/Agent of Nissan Tanaka

Other items of Nissan Tanaka

Request the quotation for Nissan Tanaka