Nissan Tanaka

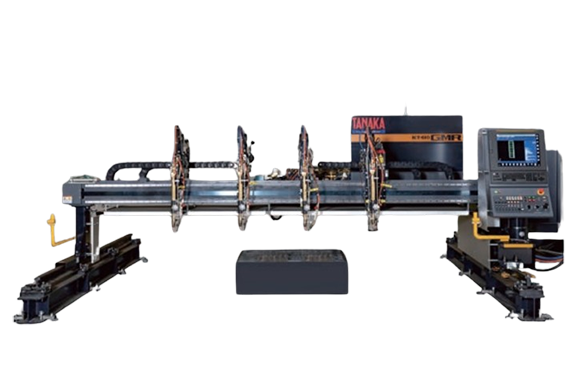

NISSAN TANAKA KT-610 GMR NC Gas Cutting Machine

Manufacturer: Nissan Tanaka

Model : KT-610 GMR

Feature

– Adopted single-side rack & pinion drive, speeding up the rapid feed & marking speed to 12m/min, achieving performance close to that of dual-side rack & pinion drive.

– The torch drive method employs steel belt drive, and by adopting the torch lifting device MT-100, the minimum torch width is ensured to be equivalent to that of the square bar specification. This allows for use in medium to large object cutting, as well as for planer applications.

– Comprehensive machine specifications: The NC device can choose between our own manufactured “RoboQ-150” and Fanuc’s “0i-LF Plus”.

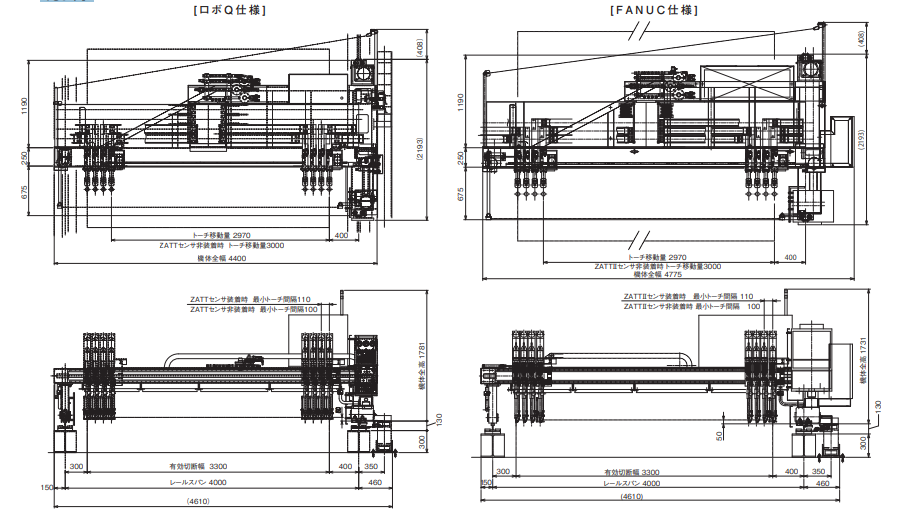

Dimensional Diagram

Specification

| Rail Span (mm) | 3,000 | 3,500 | 4,000 | 4,500 |

|---|---|---|---|---|

| Effective Cutting Width (mm) | 2,300 | 2,800 | 3,300 | 3,800 |

| Cross Stroke (mm) | 2,000※ | 2,500 ※ | 3000※ | 3,500 ※ |

| Standard Rail Length (mm) | 9,600 (can be extended at 1,200mm pitch) | |||

| Effective Cutting Length (mm) | 7,100 (Rail length –2,500) | |||

| Rapid Feed Rate (mm/min) | 12,000 | |||

| Marking Speed (mm/min) | 12,000 | |||

| Cutting Speed (mm/min) | 50~1,000 | |||

| Standard Number of Cutting Torches | 4 units (up to a maximum of 8 units) | |||

| Rail Size | 22 kg/m (CP5) rails (option to choose 37 kg/m (CP6) rails) | |||

| Drive Method | X-axis single-side rack & pinion drive Y-axis rack & pinion plus steel belt drive | |||

| Implementation Method | Hose hanger/cable bear selectable | |||

| NC Device | Robo Q-150 FANUC Series 0i-LF Plus | |||

| Option | Water spraying/steel plate height following/automatic ignition/Z marking/air plasma equipped Double heat shield/under-girder air blow/thick plate cutting function/automatic flame adjustment device/torch interval automatic setting device | |||

Kouei is Distributor/Agent of Nissan Tanaka

Other items of Nissan Tanaka

Request the quotation for Nissan Tanaka