Nissan Tanaka

NISSAN TANAKA KT-650J NC Gas Cutting Machine

Manufacturer: Nissan Tanaka

Model : KT-650J

Feature

This is the sister machine of the gantry type KT-650 equipped with dual-side rack & pinion. For the NC control device, TANAKA’s top-of-the-line ROBOCUT series Robo Q-150 is adopted, focusing on operability and maintainability as a model.

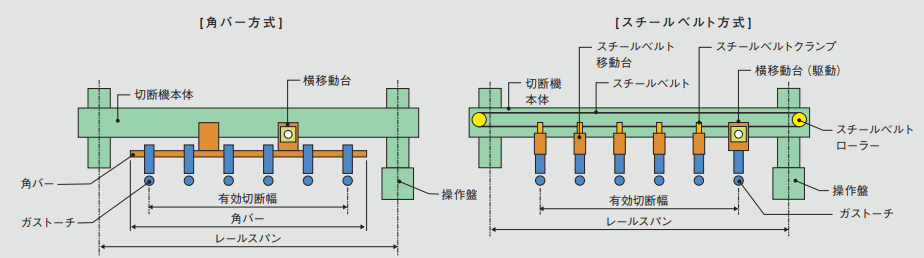

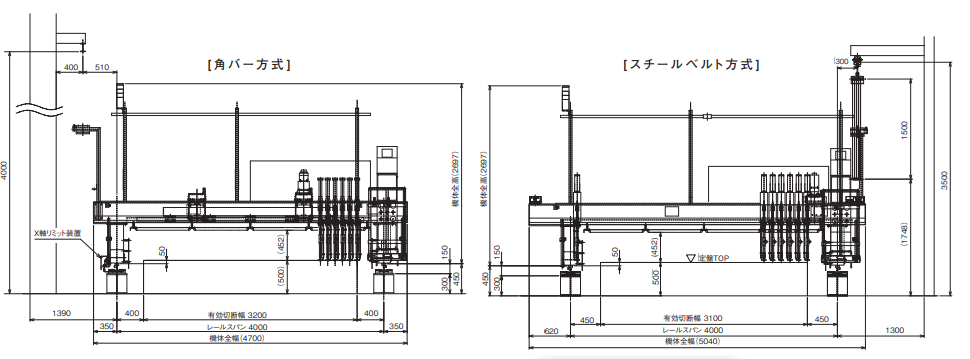

Types of Horizontal Drive Methods

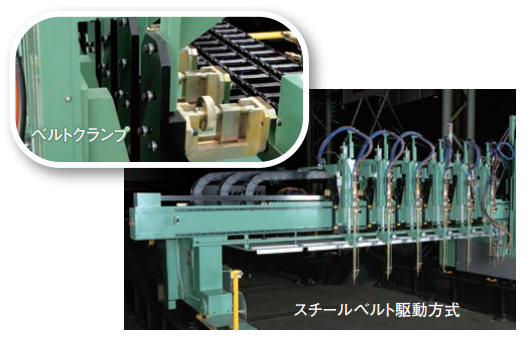

- A method where the gas torch is mounted on a square bar connected to the moving table, and the entire square bar is moved. It is a drive method advantageous for small item shape cutting and planer cutting with multiple torches, suitable for low-variety and high-volume production.

- A method in which each gas torch is equipped with a lateral moving table and connected by a steel belt for movement. This allows for cutting of large-sized materials with a significant horizontal axis stroke, installation of square bars in spaces where they cannot protrude from the machine body, and simultaneous mirror cutting by using clamps on the front and rear sides of the steel belt.

Dimensional Diagram of KT-650J

Specification

| Rail Span (mm) | 4,000~6,000 | |

| Effective Cutting Width (mm) | Rail span -900 | |

| Rail Length (mm) | Standard 9,600 (Extendable in increments of 1,200) | |

| Effective Cutting Length (mm) | Rail Length: -2,500 (For a rail length of 9,600, it becomes 7,100) | |

| Horizontal Drive Method | Square Bar Method | Steel Belt Method |

| Single Torch Stroke (mm) | 1,500~2,500mm | Variable depending on the number of torches |

| Number of Blowpipes | Standard 6 units (up to a maximum of 16 units) | Standard 6 units (up to a maximum of 8 units) |

| Rapid Feed/Marking Speed (mm/min) | 12,000 | |

| NC Device | Robo Q-150 | |

| Drive Method | Dual-Side Rack & Pinion | |

| Rail Size (kg/m) | 37 OR 50 | |

Kouei is Distributor/Agent of Nissan Tanaka

Other items of Nissan Tanaka

Request the quotation for Nissan Tanaka