Nissan Tanaka

NISSAN TANAKA LMRV Revolutionary Main Laser Processing

Manufacturer: NISSAN TANAKA

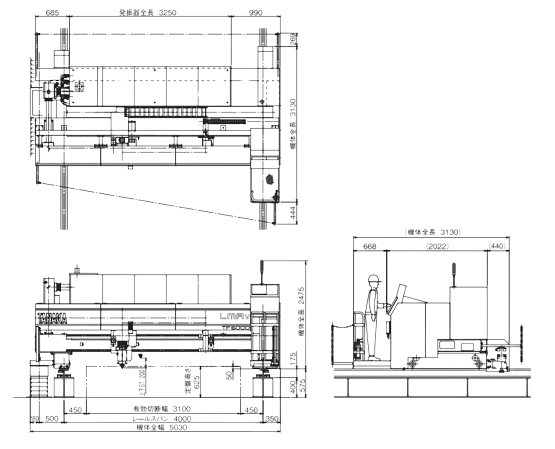

Model: LMRV: TF2000, TF4000, TF6000

Features

Power Options 2kW・4kW・6kW

Small-scale processing is possible with the fiber laser cutting machine TF6000 (6kW), TF4000 (4kW), and TF2000 (2kW), which can handle workpieces up to 3 mm thick. A single machine can perform cutting, marking, and surface processing with high precision.

Diverse Head Options

Our laser cutting machines can be equipped with a variety of cutting heads ranging from 2.6mm to 5.6mm, enabling fine control of the laser beam. This allows for optimal processing quality for different material thicknesses.

Automatic Lens Cleaning System

With just one button, the machine automatically cleans the lens, ensuring that the cutting quality is consistently high. This system greatly reduces the frequency of lens contamination, which can lead to costly downtime. The cleaning process maintains 10%-15% higher efficiency compared to manual cleaning, ensuring a stable production process.

Stable Cutting Performance

The stable beam output ensures consistent cutting quality. Furthermore, the machine is equipped with O.S. (Operating System) to control the beam quality, improving the cutting performance for materials like copper and brass.

Specifications

| Model | 25 | 30 | 35 | 40 | 45 | 50 | 55 | |||||||

| Maximum Cutting Size (mm) | 2,600 | 3,100 | 3,600 | 4,100 | 4,600 | 5,100 | 5,600 | |||||||

| X/Y Axis Stroke (mm) | 3,500 | 3,800 | 4,000 | 4,300 | 4,500 | 4800 | 5,000 | 5300 | 5,500 | 5800 | 6,000 | 6500 | 6,500 | 7000 |

| Maximum Material Weight | 50kg/m² (LMRV25~LMRV35) TF2000: TF4000: 37kg/m² (increase to 3,000) | |||||||||||||

| Z Axis Stroke (mm) | 200 | |||||||||||||

| Machine Length (mm) | 3,130 | |||||||||||||

| Machine Width (mm) | 4,530 | 4,830 | 5,030 | 5,330 | 5,530 | 5,830 | 6,030 | 6,330 | 6,530 | 6,830 | 7,130 | 7,530 | 7,630 | 8,030 |

| Machine Height (mm) | 2,475 (LMRV25~35) 2,575 (LMRV40~55) | |||||||||||||

| Machine Weight (kg) (TF4000: 400kg, TF6000: 500kg, TF2000: 300kg) | 4,300 | 4,400 | 4,500 | 5,200 | 5,400 | 5,900 | 6,200 | |||||||

Machine Cooling Method

| Equipment | Quantity |

|---|---|

| Plasma Source | 1 unit |

| Fiber Laser Cutting Machine (TF2000/TF4000/TF6000) | 1 unit |

| NC Control (FANUC SERIES 31iLB PANELi) | 1 unit |

| Water Cooling Equipment | 1 unit |

Remote Specifications

| Performance Parameter | Speed |

|---|---|

| Cutting Speed Range | 1 ~ 6,000 mm/min |

| Rapid Traverse Speed | 24,000 mm/min |

| Approach Speed | 12,000 mm/min |

| Plasma Cutting Speed | 20,000 mm/min |

| Plasma Beveling Speed | 15,000 mm/min |

| Drilling Speed | 24,000 mm/min |

Cooling Water Circulation Device

| Model | TF2000 | TF4000 | TF6000 |

|---|---|---|---|

| Model Name | RKL-5500-GTA-B | RKE-12000A-VTA | RKE-22000A-VTA |

| External Dimensions (L×W×H) | 1,404×800×1,780 | 1,440×930×1,800 | 2,010×1,200×2,190 |

| Cooling Water Quantity/Capacity | 390Kg / 140L | 550Kg / 160L | 1,050Kg / 250L |

Standard Cutting Specifications

| Specification | TF2000 | TF4000 | TF6000 |

|---|---|---|---|

| Maximum Cutting Thickness | 19mm | 22mm | 32mm |

| For Pressure <1MPa Oxygen Cutting | 8mm (10mm) | 8mm (10mm) | 12mm (16mm) |

| For Pressure ≥1MPa Oxygen Cutting | — | 16mm (20mm) | 20mm (28mm) |

| Air Cutting | — | — | 25mm |

Kouei is Distributor/Agent of Nissan Tanaka

Other items of Nissan Tanaka

Request the quotation for Nissan Tanaka

Related Products

-

NISSAN TANAKA SANARC SUPER DRYTUBE

-

NISSAN TANAKA TE-140 series, TE-140A Vacuum Generator For Semiconductor Use

-

NISSAN TANAKA TORR-1300 Pressure Regulator For Semiconductors

-

NISSAN TANAKA COMET(CMH Series) Industrial Pressure Regulator

-

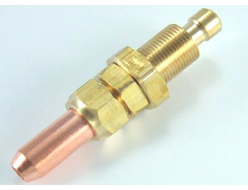

NISSAN TANAKA Nozzle For Cutting, Welding, Heating

-

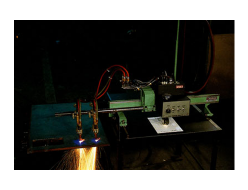

NISSAN TANAKA KT-510GX Photo Tracer Type Gas Cutting Machine