Nissan Tanaka

NISSAN TANAKA TORR-1300 Pressure Regulator For Semiconductors

Manufacturer: Nissan Tanaka

Model: TORR-1300

High-pressure, standard model for primary side high pressure: TORR-1300

Features

- The TORR series has earned high trust due to its long track record and is a pressure regulator that can be considered a synonym for “pressure regulators for semiconductor gases.”

- We assemble it in a class 1000 clean room with all parts being of the 0.3μm class.

- We have integrated a filter in the primary chamber’s flow path to reduce internal leaks.

- We conduct helium leak tests and perform shipment inspections for all items.

- We also offer the option to manufacture electrolytic polishing specifications (with a surface roughness of Ra0.25μm) for gas-contacting metal parts.

- Users widely utilize the TORR-1300 series as a standard model for primary pressure reduction equipment, such as cylinder cabinets, for primary high-pressure applications.

Basic Specifications

Use materials

Gas connection part

Main body: SUS316L

Diaphragm: SUS316L

Filter: SUS316

Pressure Gauge: SUS316L (Threaded Connection)

Joint or fitting: SUS316L (Welded connection)

Other gas contact parts: SUS316L, SUS316, Fluororesin

Non-contact gas part

Cap: C3771

Pressure regulating handle: ABS plastic, C3604

Performance

Inlet side maximum working pressure: 15MPa

Outlet side maximum working pressure: 1.0MPa

Maximum flow rate: 550L/min(nor)(P1=10MPa, P2=1.0MPa, N₂ GAS)

Operating temperature: -5~40℃

Weight: 1.3kg (4 ports)

Built-in filter filtration degree: 5μm

Diameter of inlet and outlet ports: 1/4″

External leak amount: 1.3×10-9Pa・m3/sec below (Threaded Connection) & 1.3×10-10Pa・m3/sec below (Welded connection)

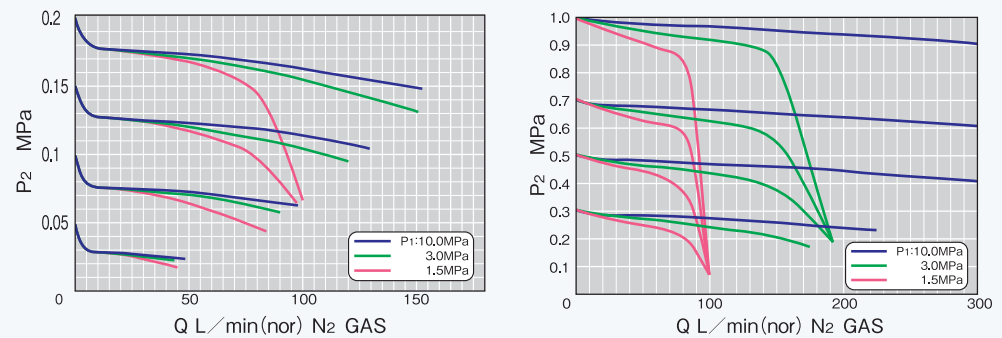

Flow Characteristics Diagram

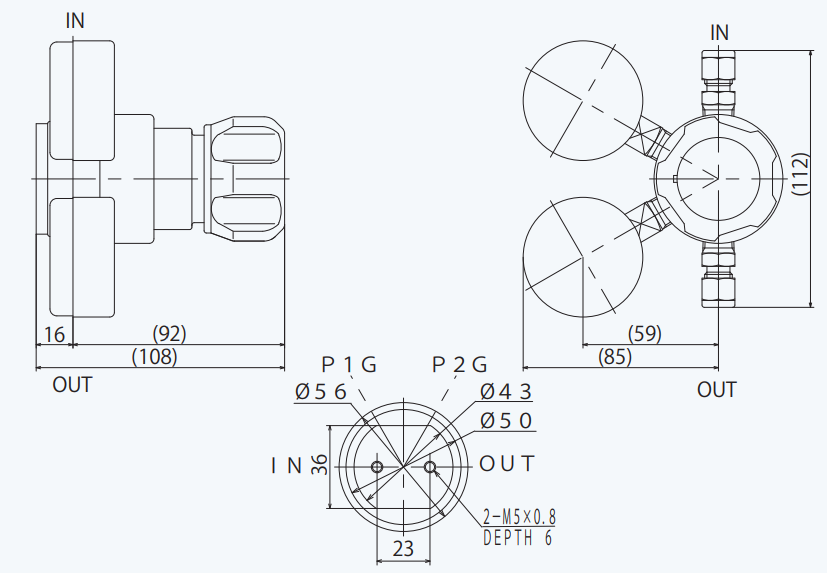

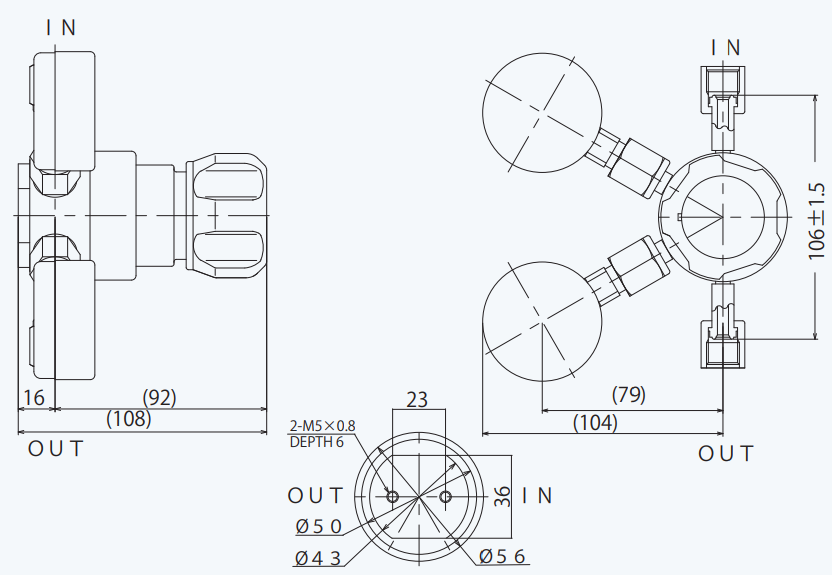

Appearance

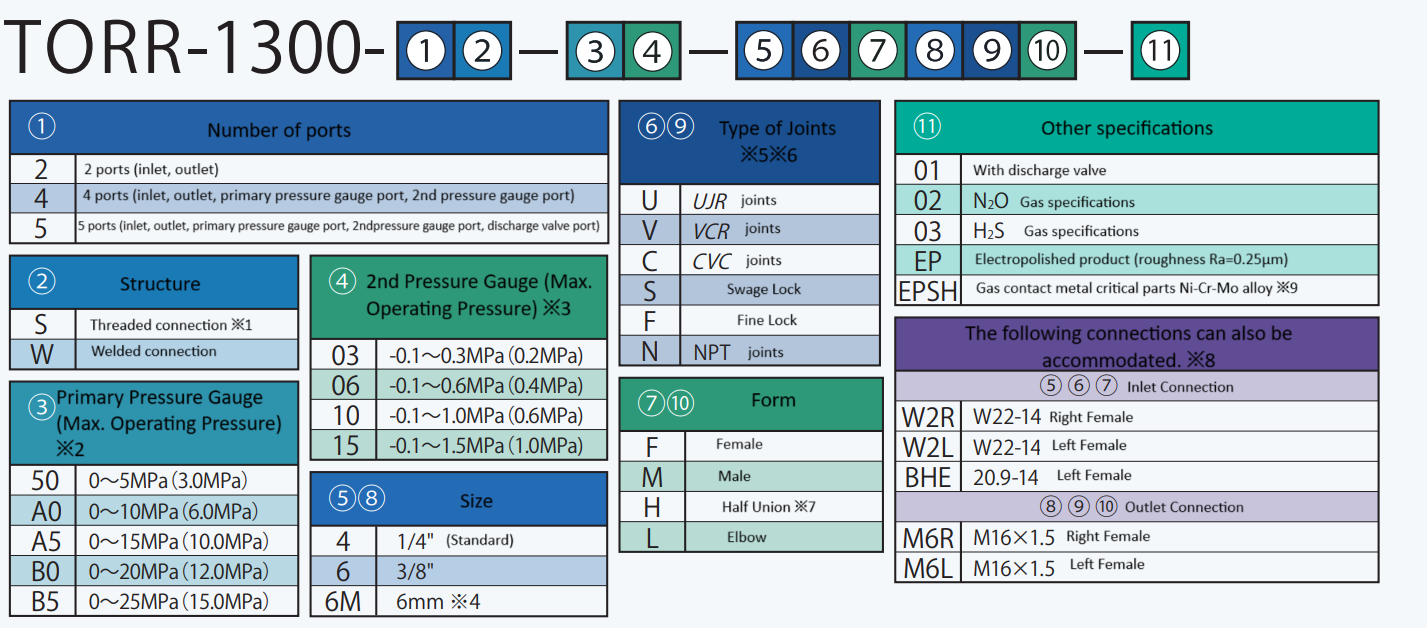

Description

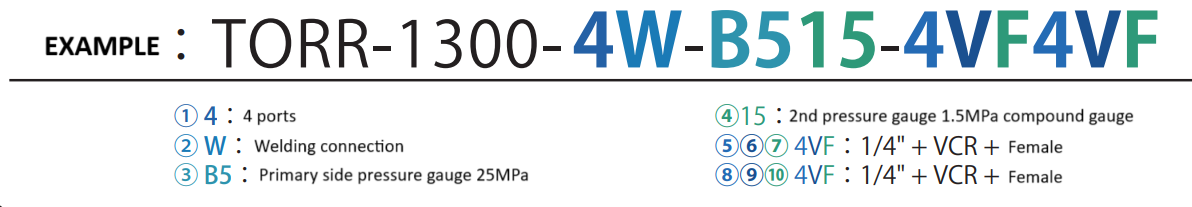

Designated Attention

※1 The “SH” series, which uses a high corrosion-resistant alloy of Ni-Cr-Mo alloy for the metal parts in contact with gas, cannot accommodate certain requirements. The Ni-Cr-Mo alloy is equivalent to the American Haynes company’s “Hastelloy C-22.”

※2 In cases without a primary side pressure gauge, the symbol will be B5.

※3 In cases without a secondary side pressure gauge, the symbol will vary depending on the pressure used.

| Operating Pressure | Symbol |

|---|---|

| ~0.2MPa | 03 |

| ~0.4MPa | 06 |

| ~0.6MPa | 10 |

| ~1.0MPa | 15 |

※ 4 Only fitting type S (Swagelok) can be selected.

※5 For other shapes, different symbols will be used.

※6 When using italic fittings, the structure will fundamentally be a welded connection. For other types of fittings, the structure will fundamentally be a threaded connection.

※7 Only fitting types S (Swagelok) and F (Finelok) can be selected.

※8If W (weld connection) is chosen for structure ②, M6R and M6L cannot be selected. W2R, W2L, and BHE will be treated as special products.

※9 Even when using the “SH” series, the material of the metal parts in contact with the gas of the pressure gauge will be SUS316L. If you require a pressure gauge with Ni-Cr-Mo alloy contact gas metal parts, please contact us.

⚠️Warning: For correct usage, please make sure to read the ‘Instruction Manual’ carefully before use.

Kouei is Distributor/Agent of Nissan Tanaka

Other items of Nissan Tanaka

Request the quotation for Nissan Tanaka

Related Products

-

NISSAN TANAKA KT-5NX Straight Line Cutting Machine

-

NISSAN TANAKA LMXVIIZ CO2 Laser Bevel Cutting Machine

-

NISSAN TANAKA REB 6, BRB 4 Pipe Beveling Machine

-

NISSAN TANAKA S-TORR V T50 Pressure Regulator For Semiconductors

-

NISSAN TANAKA COMET(CML Series) Industrial Pressure Regulator

-

NISSAN TANAKA TORR-3300 Series Pressure Regulator For Semiconductors