Japan, Nitta

Nitta Flame Resistant Tubing

Product Made in Japan

Manufacturer: Nitta

Product’s name: Flame Resistant Tubing

[For spot welded piping] Flexible flame-retardant tube FUK

| Fluid used | Air |

Water |

|---|---|---|

| Operating temperature limit | -40℃~ +80℃ | 0℃~ +60℃ |

| Maximum working pressure | 0.7~ 0.8MPa | 0.6~ 0.7MPa |

Adopts a flame-retardant resin for the outer layer.

Excellent in flexibility, abrasion resistance and sliding properties.

With no need to peel off the outer layer.

Our line-up of products with increased inner diameters contributes to the increase in flow volume.

[For spot welded piping] Flame-retardant tube FS

| Fluid used | Air |

Water |

|---|---|---|

| Operating temperature limit | -40℃~ +100℃ | 0℃~ +70℃ |

| Maximum working pressure | 0.7~ 1.2MPa | |

Tubes which utilize a flame-retardant resin.

Our line-up of products with increased inner diameters contributes to the increase in flow volume.

Markings along the tubing as an insertion length indicator.

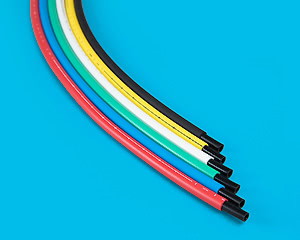

[For spot welding piping] Flame-retardant tube FW (2 layers)

| Fluid used | Air |

Water |

|---|---|---|

| Operating temperature limit | -40℃~ +80℃ | 0℃~ +70℃ |

| Maximum working pressure | 0.8~ 1.0MPa | |

A double-layer structure with a flame-retardant resin for inner and outer layers.

Markings along the tubing as an insertion length indicator.

Before using FW tubes, peel off outer covers with Nitta’s special cutter (TC02, TC03).

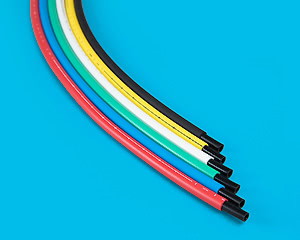

[For spot welding piping] Flame-retardant tube FWU (2 layers, flexible)

| Fluid used | Air |

Water |

|---|---|---|

| Operating temperature limit | -40℃~ +80℃ | 0℃~ +50℃ |

| Maximum working pressure | 0.6~ 0.9MPa | |

Tubes with higher flexibility than FW, with a double-layer structure which utilizes a flame-retardant resin for the outer layer and an ether-based polyurethane resin for the inner layer.

Ether polyurethane resin for the inner layer is used to prevent degradation by water or mold under high temperature and high humidity.

Markings along the tubing as an insertion length indicator.

Related Products

-

Kyowa PS-05KC PS-C Miniature Pressure Sensor

-

IKURATOOLS ISK-RC16LE Cordless Rebar Cutter

-

IMADA TAA-MTS-TB series Torque-Angle Measurement Unit

-

WINOA IKK Stainless Cut Wire

-

Ascon BP-0 General-purpose manual machine (suction type) Blast Cabinet

-

Automatic Ultrasonic Flaw Detector For Differential Case Laser Welds