Okabe

Okabe B90-0410 Metal Lath Formwork

Product Made in Japan

Manufacturer: Okabe

Model: B90-0410

Stay-in-place lath formwork for footing beam work

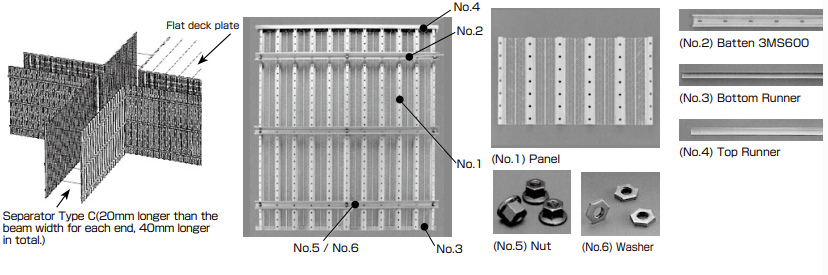

◆Parts

| No | Component Parts | Size (mm) | Weight (PC) | Quantity (pc/bundle) | Packing |

|---|---|---|---|---|---|

| 1 | Panel | W=600 | 1.70 (kg/m) | – | – |

| 2 | Batten 3MS600 | 3060 | 2.60 (kg) | 20 | Secured with PP strap |

| 3 | Bottom Runner | 2000 | 0.38 (kg) | 50 | Secured with PP strap |

| 4 | Top Runner | 2500 | 0.67 (kg) | 50 | Secured with PP strap |

| 5 | Nut (set outside the panel) | Distance between the parallel sides: 14 | 0.015 (kg) | 2,000 nuts (500 nuts x 4 bags) | Case |

| 6 | Washer (set inside the panel) | Distance between the parallel sides: 14 | 0.003 (kg) | 4,000 nuts (200 nuts x 20 bags) | Case |

| 7 | Joint | For φ10 hole | – | 5,000 nuts (1,000 nuts x 5 bags) | Case |

Note 1: The standard height of the Panel is 500~4,000mm. Please consult our salesperson when you need

taller / shorter height.

Note 2: The product is used to receive flat deck plates when the concrete slab is placed at the same time

◆Application

● All foundation construction

● For Buildings: footing beam, footing, strip footing, mat foundation, pressure-resisting board, concrete stopper, etc.

● For Civil engineering construction: pillar foundation, retaining wall, concrete block, construction joint, etc.

● For other construction: steel tower foundation, wind turbine tower foundation.turbine tower foundation

Features

● Efficient formwork installation: Fully systemized component parts of the product streamline the installation of formwork panels.

● No need for formwork removal: All components of the products are permanent. No need for formwork removal after concrete solidification, but just burying them in the ground.

● Can place slab concrete simultaneously with f: The vertical members of panels are highly rigid. Placing slab concrete simultaneously with footing beam concrete is applicable with flat deck

plates.

● Space-saving: The volume of materials carried in is 1/7 compared with plywood panels, and the volume carried out is zero as no need for formwork removal.

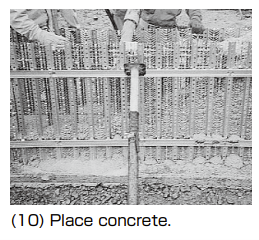

● Concrete filling conditions can be checked: Concrete filling conditions can be visually checked because of the use of steel netting for formwork panels so that quality control is easy.

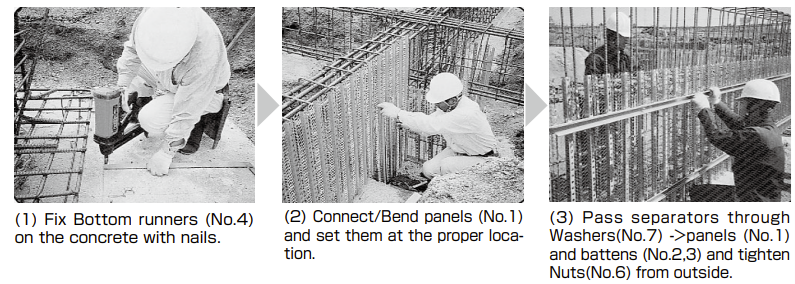

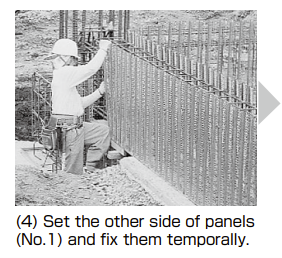

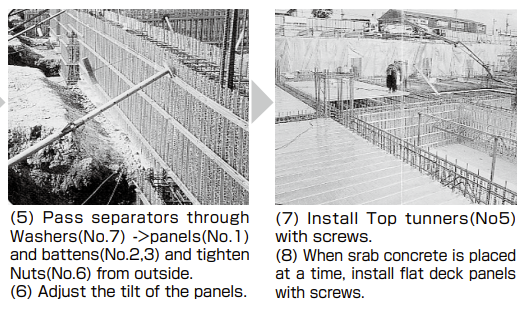

◆How to use

Cautions

● Please read and understand the Technical Manual (W600) before executing or designing construction work.

◆Name of component parts